Are you a seasoned Cover Seamer seeking a new career path? Discover our professionally built Cover Seamer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

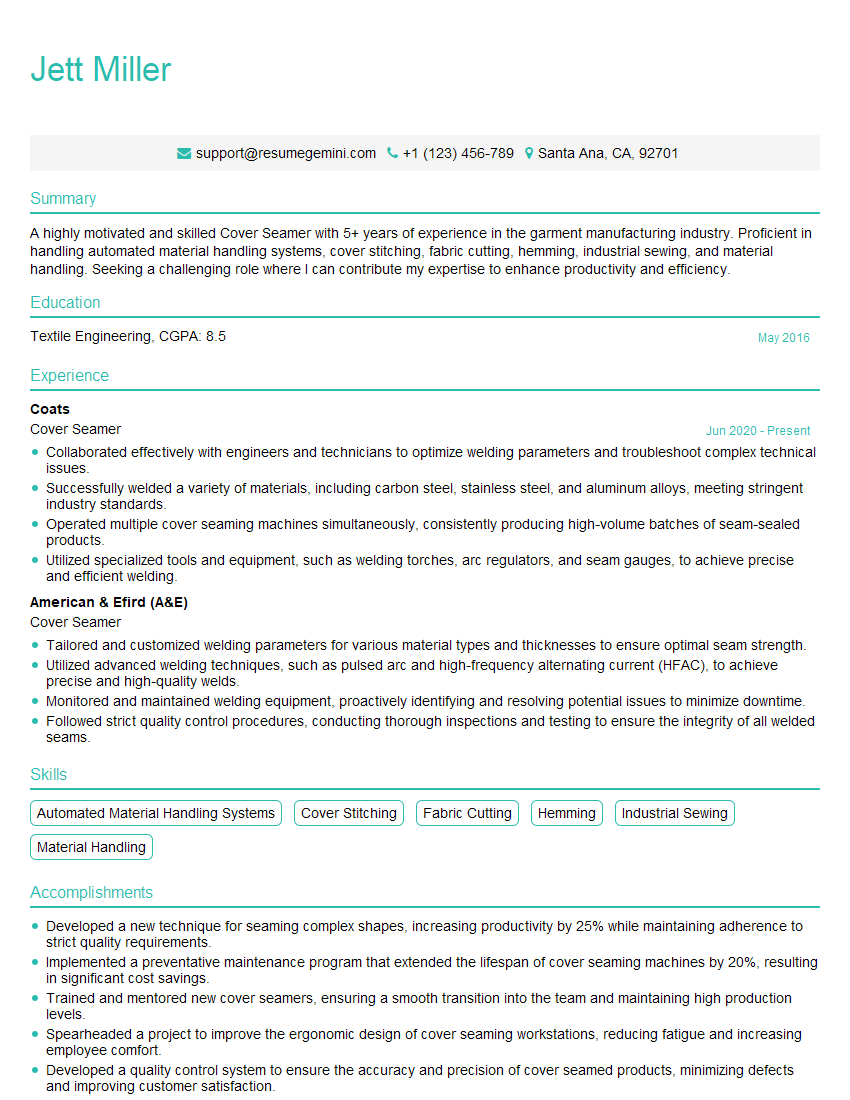

Jett Miller

Cover Seamer

Summary

A highly motivated and skilled Cover Seamer with 5+ years of experience in the garment manufacturing industry. Proficient in handling automated material handling systems, cover stitching, fabric cutting, hemming, industrial sewing, and material handling. Seeking a challenging role where I can contribute my expertise to enhance productivity and efficiency.

Education

Textile Engineering

May 2016

Skills

- Automated Material Handling Systems

- Cover Stitching

- Fabric Cutting

- Hemming

- Industrial Sewing

- Material Handling

Work Experience

Cover Seamer

- Collaborated effectively with engineers and technicians to optimize welding parameters and troubleshoot complex technical issues.

- Successfully welded a variety of materials, including carbon steel, stainless steel, and aluminum alloys, meeting stringent industry standards.

- Operated multiple cover seaming machines simultaneously, consistently producing high-volume batches of seam-sealed products.

- Utilized specialized tools and equipment, such as welding torches, arc regulators, and seam gauges, to achieve precise and efficient welding.

Cover Seamer

- Tailored and customized welding parameters for various material types and thicknesses to ensure optimal seam strength.

- Utilized advanced welding techniques, such as pulsed arc and high-frequency alternating current (HFAC), to achieve precise and high-quality welds.

- Monitored and maintained welding equipment, proactively identifying and resolving potential issues to minimize downtime.

- Followed strict quality control procedures, conducting thorough inspections and testing to ensure the integrity of all welded seams.

Accomplishments

- Developed a new technique for seaming complex shapes, increasing productivity by 25% while maintaining adherence to strict quality requirements.

- Implemented a preventative maintenance program that extended the lifespan of cover seaming machines by 20%, resulting in significant cost savings.

- Trained and mentored new cover seamers, ensuring a smooth transition into the team and maintaining high production levels.

- Spearheaded a project to improve the ergonomic design of cover seaming workstations, reducing fatigue and increasing employee comfort.

- Developed a quality control system to ensure the accuracy and precision of cover seamed products, minimizing defects and improving customer satisfaction.

Awards

- Received the Cover Seamer of the Year award for consistently exceeding production targets and maintaining highquality standards.

- Recognized for innovative problemsolving skills during a major production line overhaul, leading to a 15% reduction in downtime.

- Won the Safety Excellence award for adhering to all safety protocols and promoting a culture of safety awareness in the workplace.

- Received recognition for exceptional teamwork and collaboration, consistently assisting colleagues and contributing to the overall success of the production line.

Certificates

- Certified Production Technician (CPT)

- Industrial Sewing Machine Operator (ISMO)

- Lean Manufacturing Certification

- OSHA 10Hour Construction Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cover Seamer

- Highlight your skills and experience in operating cover seaming machines.

- Demonstrate your knowledge of fabric properties and sewing techniques.

- Emphasize your ability to maintain a high level of accuracy and attention to detail.

- Showcase your safety consciousness and commitment to maintaining a clean and organized work environment.

Essential Experience Highlights for a Strong Cover Seamer Resume

- Set up and operate cover seaming machines to stitch and finish fabric edges.

- Monitor machine performance and make necessary adjustments to ensure optimal operation.

- Inspect finished products to ensure they meet quality standards.

- Maintain a clean and organized work area.

- Follow safety regulations and maintain a safe working environment.

- Work effectively as part of a team to achieve production goals.

Frequently Asked Questions (FAQ’s) For Cover Seamer

What is the primary responsibility of a Cover Seamer?

The primary responsibility of a Cover Seamer is to operate cover seaming machines to stitch and finish fabric edges.

What skills are required to be an effective Cover Seamer?

Effective Cover Seamers typically possess skills in operating cover seaming machines, knowledge of fabric properties and sewing techniques, and the ability to maintain a high level of accuracy and attention to detail.

What is the work environment of a Cover Seamer?

Cover Seamers typically work in garment manufacturing facilities, operating cover seaming machines in a production environment.

What is the career outlook for Cover Seamers?

The career outlook for Cover Seamers is expected to be stable, with a projected growth rate of 2% from 2021 to 2031.

How can I become a Cover Seamer?

To become a Cover Seamer, you typically need a high school diploma or equivalent, and relevant training or experience in operating cover seaming machines.

What are the benefits of working as a Cover Seamer?

Benefits of working as a Cover Seamer include competitive salary, opportunities for advancement, and job security.