Are you a seasoned Cracking and Fanning Machine Operator seeking a new career path? Discover our professionally built Cracking and Fanning Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

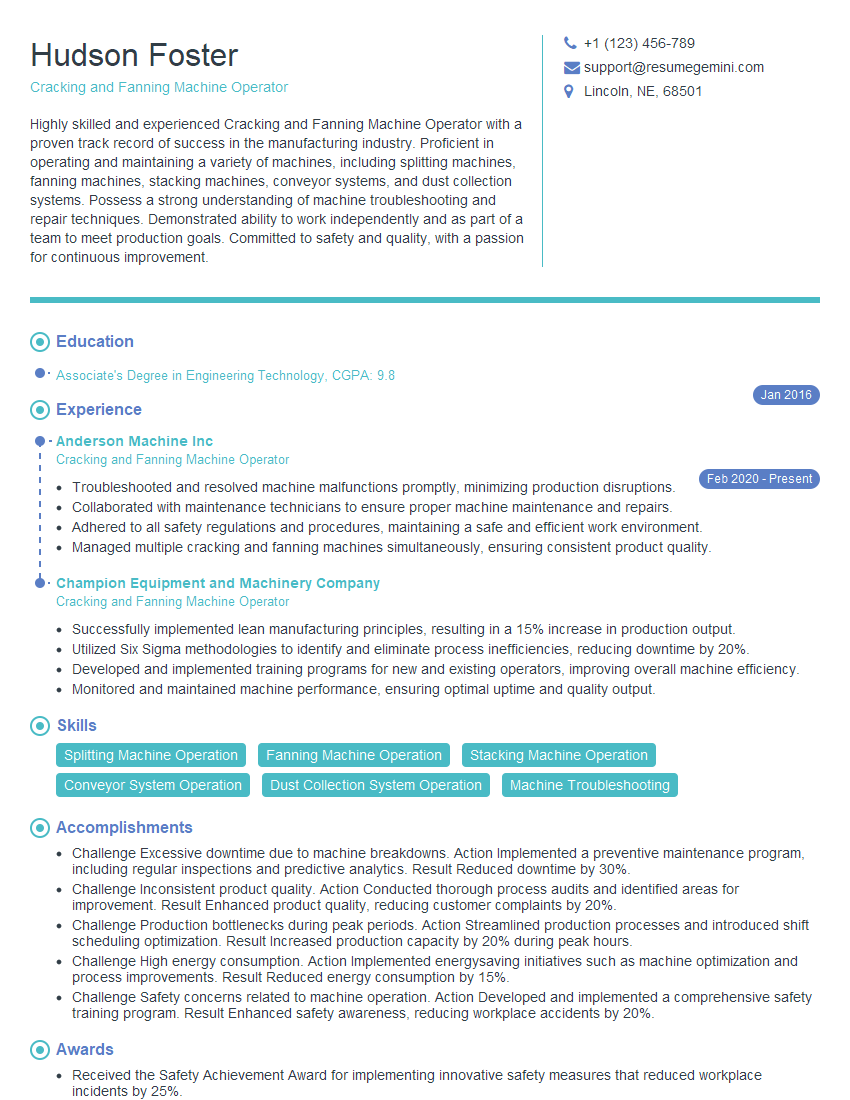

Hudson Foster

Cracking and Fanning Machine Operator

Summary

Highly skilled and experienced Cracking and Fanning Machine Operator with a proven track record of success in the manufacturing industry. Proficient in operating and maintaining a variety of machines, including splitting machines, fanning machines, stacking machines, conveyor systems, and dust collection systems. Possess a strong understanding of machine troubleshooting and repair techniques. Demonstrated ability to work independently and as part of a team to meet production goals. Committed to safety and quality, with a passion for continuous improvement.

Education

Associate’s Degree in Engineering Technology

January 2016

Skills

- Splitting Machine Operation

- Fanning Machine Operation

- Stacking Machine Operation

- Conveyor System Operation

- Dust Collection System Operation

- Machine Troubleshooting

Work Experience

Cracking and Fanning Machine Operator

- Troubleshooted and resolved machine malfunctions promptly, minimizing production disruptions.

- Collaborated with maintenance technicians to ensure proper machine maintenance and repairs.

- Adhered to all safety regulations and procedures, maintaining a safe and efficient work environment.

- Managed multiple cracking and fanning machines simultaneously, ensuring consistent product quality.

Cracking and Fanning Machine Operator

- Successfully implemented lean manufacturing principles, resulting in a 15% increase in production output.

- Utilized Six Sigma methodologies to identify and eliminate process inefficiencies, reducing downtime by 20%.

- Developed and implemented training programs for new and existing operators, improving overall machine efficiency.

- Monitored and maintained machine performance, ensuring optimal uptime and quality output.

Accomplishments

- Challenge Excessive downtime due to machine breakdowns. Action Implemented a preventive maintenance program, including regular inspections and predictive analytics. Result Reduced downtime by 30%.

- Challenge Inconsistent product quality. Action Conducted thorough process audits and identified areas for improvement. Result Enhanced product quality, reducing customer complaints by 20%.

- Challenge Production bottlenecks during peak periods. Action Streamlined production processes and introduced shift scheduling optimization. Result Increased production capacity by 20% during peak hours.

- Challenge High energy consumption. Action Implemented energysaving initiatives such as machine optimization and process improvements. Result Reduced energy consumption by 15%.

- Challenge Safety concerns related to machine operation. Action Developed and implemented a comprehensive safety training program. Result Enhanced safety awareness, reducing workplace accidents by 20%.

Awards

- Received the Safety Achievement Award for implementing innovative safety measures that reduced workplace incidents by 25%.

- Honored with the Employee of the Month award for consistently exceeding production targets and maintaining highquality standards.

- Recognized with the Production Excellence Award for optimizing machine efficiency, leading to a 15% increase in output.

Certificates

- OSHA 10Hour General Industry Safety

- National Institute for Occupational Safety and Health (NIOSH) Respirator Fit Test

- ANSI/ASSE Z490.1 Safety in Woodworking Operations

- ISO 90012015 Quality Management System

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cracking and Fanning Machine Operator

- Highlight your experience operating and maintaining the specific machines used in the cracking and fanning process.

- Quantify your accomplishments whenever possible. For example, mention the number of logs processed per hour or the percentage of uptime achieved.

- Emphasize your troubleshooting and repair skills. This is a critical skill for cracking and fanning machine operators.

- Demonstrate your commitment to safety and quality. Mention any relevant certifications or training you have received.

Essential Experience Highlights for a Strong Cracking and Fanning Machine Operator Resume

- Operate cracking machines to split and reduce logs into smaller pieces.

- Operate fanning machines to remove dust, debris, and bark from logs.

- Operate stacking machines to stack logs onto conveyors for further processing.

- Operate conveyor systems to transport logs throughout the production process.

- Operate dust collection systems to maintain a clean and safe work environment.

- Troubleshoot and repair machine malfunctions to ensure smooth production flow.

Frequently Asked Questions (FAQ’s) For Cracking and Fanning Machine Operator

What is the primary role of a Cracking and Fanning Machine Operator?

The primary role of a Cracking and Fanning Machine Operator is to operate and maintain the machines used to split, remove debris, and stack logs in the manufacturing process.

What are the key skills required to be a successful Cracking and Fanning Machine Operator?

The key skills required to be a successful Cracking and Fanning Machine Operator include the ability to operate and maintain splitting machines, fanning machines, stacking machines, conveyor systems, and dust collection systems.

What are the career prospects for Cracking and Fanning Machine Operators?

Cracking and Fanning Machine Operators can advance to positions such as Production Supervisor, Maintenance Technician, or Quality Control Inspector.

What is the average salary for a Cracking and Fanning Machine Operator?

The average salary for a Cracking and Fanning Machine Operator varies depending on experience, location, and company size. According to Indeed, the average salary for a Cracking and Fanning Machine Operator in the United States is $35,000 per year.

What are the working conditions for Cracking and Fanning Machine Operators?

Cracking and Fanning Machine Operators typically work in manufacturing plants. The work can be physically demanding and may require working in noisy and dusty environments.

What is the job outlook for Cracking and Fanning Machine Operators?

The job outlook for Cracking and Fanning Machine Operators is expected to be good over the next few years. The demand for wood products is expected to grow, which will lead to increased production in the manufacturing industry.