Are you a seasoned Crankshaft Grinder seeking a new career path? Discover our professionally built Crankshaft Grinder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

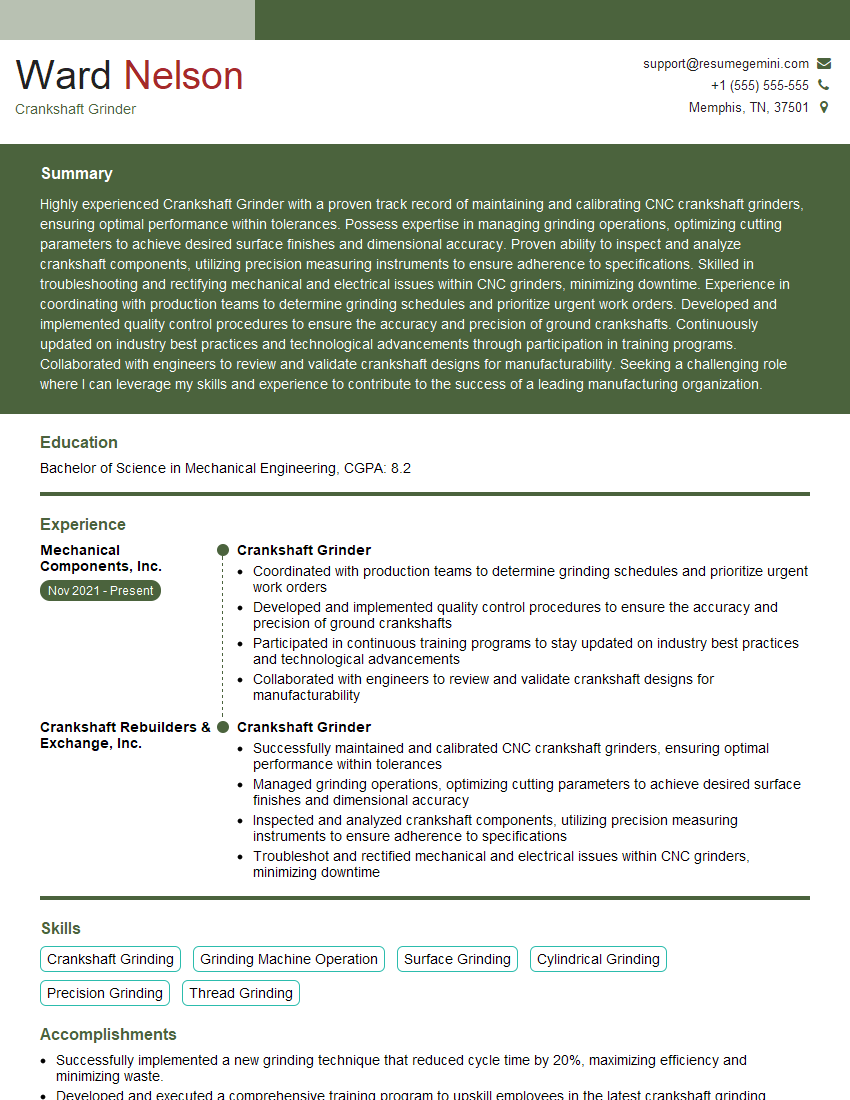

Ward Nelson

Crankshaft Grinder

Summary

Highly experienced Crankshaft Grinder with a proven track record of maintaining and calibrating CNC crankshaft grinders, ensuring optimal performance within tolerances. Possess expertise in managing grinding operations, optimizing cutting parameters to achieve desired surface finishes and dimensional accuracy. Proven ability to inspect and analyze crankshaft components, utilizing precision measuring instruments to ensure adherence to specifications. Skilled in troubleshooting and rectifying mechanical and electrical issues within CNC grinders, minimizing downtime. Experience in coordinating with production teams to determine grinding schedules and prioritize urgent work orders. Developed and implemented quality control procedures to ensure the accuracy and precision of ground crankshafts. Continuously updated on industry best practices and technological advancements through participation in training programs. Collaborated with engineers to review and validate crankshaft designs for manufacturability. Seeking a challenging role where I can leverage my skills and experience to contribute to the success of a leading manufacturing organization.

Education

Bachelor of Science in Mechanical Engineering

October 2017

Skills

- Crankshaft Grinding

- Grinding Machine Operation

- Surface Grinding

- Cylindrical Grinding

- Precision Grinding

- Thread Grinding

Work Experience

Crankshaft Grinder

- Coordinated with production teams to determine grinding schedules and prioritize urgent work orders

- Developed and implemented quality control procedures to ensure the accuracy and precision of ground crankshafts

- Participated in continuous training programs to stay updated on industry best practices and technological advancements

- Collaborated with engineers to review and validate crankshaft designs for manufacturability

Crankshaft Grinder

- Successfully maintained and calibrated CNC crankshaft grinders, ensuring optimal performance within tolerances

- Managed grinding operations, optimizing cutting parameters to achieve desired surface finishes and dimensional accuracy

- Inspected and analyzed crankshaft components, utilizing precision measuring instruments to ensure adherence to specifications

- Troubleshot and rectified mechanical and electrical issues within CNC grinders, minimizing downtime

Accomplishments

- Successfully implemented a new grinding technique that reduced cycle time by 20%, maximizing efficiency and minimizing waste.

- Developed and executed a comprehensive training program to upskill employees in the latest crankshaft grinding technologies.

- Identified and resolved a critical issue in the grinding process, preventing potential equipment damage and production delays.

- Successfully implemented lean manufacturing principles, reducing setup times and optimizing material flow in the crankshaft grinding area.

- Developed a preventative maintenance program that extended the lifespan of crankshaft grinding equipment, reducing downtime and maintenance costs.

Awards

- Recognized for outstanding contributions to the crankshaft grinding process, resulting in a significant increase in productivity.

- Awarded Employee of the Quarter for exceptional performance and dedication to maintaining the highest standards in crankshaft grinding.

- Received industry recognition for innovative ideas that contributed to the advancement of crankshaft grinding practices.

- Honored with a Safety Star award for maintaining an exemplary safety record in the crankshaft grinding department.

Certificates

- Certified Crankshaft Grinder

- ISO 9001:2015

- ASME B46.1

- ANSI B25.1

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Crankshaft Grinder

Highlight your technical skills and experience

: Quantify your accomplishments and provide specific examples of your work.Emphasize your problem-solving abilities

: Describe how you have successfully resolved complex technical issues.Showcase your teamwork skills

: Highlight your ability to collaborate with others in a fast-paced manufacturing environment.Tailor your resume to each job application

: Research the company and specific job requirements to ensure your resume is relevant.

Essential Experience Highlights for a Strong Crankshaft Grinder Resume

- Successfully maintained and calibrated CNC crankshaft grinders, ensuring optimal performance within tolerances.

- Managed grinding operations, optimizing cutting parameters to achieve desired surface finishes and dimensional accuracy.

- Inspected and analyzed crankshaft components, utilizing precision measuring instruments to ensure adherence to specifications.

- Troubleshot and rectified mechanical and electrical issues within CNC grinders, minimizing downtime.

- Coordinated with production teams to determine grinding schedules and prioritize urgent work orders.

- Developed and implemented quality control procedures to ensure the accuracy and precision of ground crankshafts.

- Participated in continuous training programs to stay updated on industry best practices and technological advancements.

Frequently Asked Questions (FAQ’s) For Crankshaft Grinder

What are the key responsibilities of a Crankshaft Grinder?

The key responsibilities of a Crankshaft Grinder include maintaining and calibrating CNC crankshaft grinders, managing grinding operations, inspecting and analyzing crankshaft components, troubleshooting and rectifying mechanical and electrical issues, and coordinating with production teams.

What qualifications are required to become a Crankshaft Grinder?

Typically, a high school diploma or equivalent is required to become a Crankshaft Grinder. Additional training or experience in machining or mechanical engineering may be beneficial.

What is the work environment of a Crankshaft Grinder?

Crankshaft Grinders typically work in manufacturing facilities, operating CNC grinders and other equipment. The work environment may be noisy and require attention to detail and safety procedures.

What are the career advancement opportunities for a Crankshaft Grinder?

With experience and additional training, Crankshaft Grinders may advance to roles such as CNC programmer, quality control inspector, or supervisor.

What are the key skills required for a Crankshaft Grinder?

Key skills for a Crankshaft Grinder include mechanical aptitude, attention to detail, problem-solving abilities, and proficiency in operating CNC grinders.

What is the average salary for a Crankshaft Grinder?

The average salary for a Crankshaft Grinder varies depending on experience, location, and industry. According to Indeed, the average salary in the United States is around $45,000 per year.