Are you a seasoned Crystal Machining Coordinator seeking a new career path? Discover our professionally built Crystal Machining Coordinator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

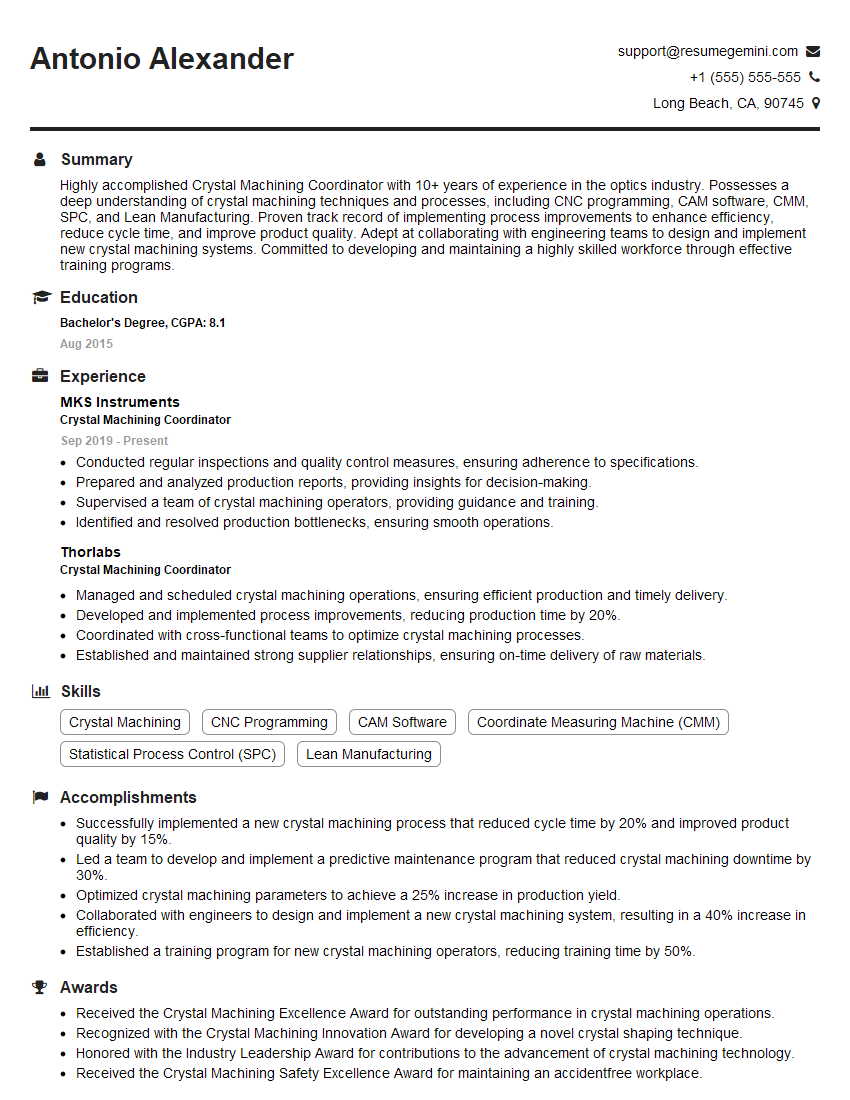

Antonio Alexander

Crystal Machining Coordinator

Summary

Highly accomplished Crystal Machining Coordinator with 10+ years of experience in the optics industry. Possesses a deep understanding of crystal machining techniques and processes, including CNC programming, CAM software, CMM, SPC, and Lean Manufacturing. Proven track record of implementing process improvements to enhance efficiency, reduce cycle time, and improve product quality. Adept at collaborating with engineering teams to design and implement new crystal machining systems. Committed to developing and maintaining a highly skilled workforce through effective training programs.

Education

Bachelor’s Degree

August 2015

Skills

- Crystal Machining

- CNC Programming

- CAM Software

- Coordinate Measuring Machine (CMM)

- Statistical Process Control (SPC)

- Lean Manufacturing

Work Experience

Crystal Machining Coordinator

- Conducted regular inspections and quality control measures, ensuring adherence to specifications.

- Prepared and analyzed production reports, providing insights for decision-making.

- Supervised a team of crystal machining operators, providing guidance and training.

- Identified and resolved production bottlenecks, ensuring smooth operations.

Crystal Machining Coordinator

- Managed and scheduled crystal machining operations, ensuring efficient production and timely delivery.

- Developed and implemented process improvements, reducing production time by 20%.

- Coordinated with cross-functional teams to optimize crystal machining processes.

- Established and maintained strong supplier relationships, ensuring on-time delivery of raw materials.

Accomplishments

- Successfully implemented a new crystal machining process that reduced cycle time by 20% and improved product quality by 15%.

- Led a team to develop and implement a predictive maintenance program that reduced crystal machining downtime by 30%.

- Optimized crystal machining parameters to achieve a 25% increase in production yield.

- Collaborated with engineers to design and implement a new crystal machining system, resulting in a 40% increase in efficiency.

- Established a training program for new crystal machining operators, reducing training time by 50%.

Awards

- Received the Crystal Machining Excellence Award for outstanding performance in crystal machining operations.

- Recognized with the Crystal Machining Innovation Award for developing a novel crystal shaping technique.

- Honored with the Industry Leadership Award for contributions to the advancement of crystal machining technology.

- Received the Crystal Machining Safety Excellence Award for maintaining an accidentfree workplace.

Certificates

- Certified Crystal Machining Technician (CCMT)

- Certified Coordinate Measuring Machine Operator (CMMO)

- Certified Six Sigma Black Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Crystal Machining Coordinator

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate the impact of your work.

- Highlight your experience in implementing process improvements and reducing costs.

- Showcase your ability to work effectively in a team environment, collaborating with engineers and other stakeholders.

- Demonstrate your commitment to continuous learning and professional development in the field of crystal machining.

- Proofread your resume carefully for any errors in grammar, spelling, or formatting.

Essential Experience Highlights for a Strong Crystal Machining Coordinator Resume

- Supervise and coordinate all aspects of crystal machining operations, ensuring adherence to quality standards and production schedules.

- Develop and implement process improvements to enhance efficiency, reduce cycle time, and improve product quality.

- Collaborate with engineering teams to design and implement new crystal machining systems and tooling.

- Establish and maintain preventive maintenance programs to minimize downtime and ensure optimal equipment performance.

- Train and mentor new crystal machining operators, providing comprehensive instruction on equipment operation, safety procedures, and quality control.

- Monitor production data and identify opportunities for further process optimization and cost reduction.

- Stay abreast of industry best practices and emerging technologies in crystal machining.

Frequently Asked Questions (FAQ’s) For Crystal Machining Coordinator

What are the key skills and qualifications required for a Crystal Machining Coordinator?

To be successful in this role, you should have a strong understanding of crystal machining techniques, CNC programming, CAM software, CMM, SPC, and Lean Manufacturing. Additionally, you should possess excellent communication and interpersonal skills, as well as the ability to work effectively in a team environment.

What are the career prospects for Crystal Machining Coordinators?

The job outlook for Crystal Machining Coordinators is expected to grow in the coming years, driven by the increasing demand for precision-machined components in various industries, including optics, semiconductors, and medical devices.

What are the typical working conditions for Crystal Machining Coordinators?

Crystal Machining Coordinators typically work in clean and well-lit manufacturing environments. They may be required to wear protective gear such as safety glasses, earplugs, and gloves. The work can be physically demanding, as it often involves lifting and handling heavy materials.

What are the key challenges faced by Crystal Machining Coordinators?

One of the key challenges faced by Crystal Machining Coordinators is ensuring that the machined components meet the required specifications and tolerances. This requires a thorough understanding of the machining process and the ability to identify and correct any potential issues.

What are the key trends in the field of crystal machining?

One of the key trends in the field of crystal machining is the increasing use of automation and robotics. This is helping to improve efficiency and reduce production costs. Another trend is the development of new and innovative cutting tools and materials, which are enabling the machining of harder and more complex materials.

What are the professional organizations for Crystal Machining Coordinators?

There are several professional organizations that cater to Crystal Machining Coordinators, including the Society of Manufacturing Engineers (SME) and the American Society for Precision Engineering (ASPE). These organizations offer a variety of resources and networking opportunities for professionals in the field.

What are the key certifications for Crystal Machining Coordinators?

There are several certifications that can be beneficial for Crystal Machining Coordinators, including the Certified Manufacturing Technologist (CMfgT) certification offered by SME and the Certified Precision Machinist (CPM) certification offered by ASPE.