Are you a seasoned Cupola Mechanic seeking a new career path? Discover our professionally built Cupola Mechanic Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

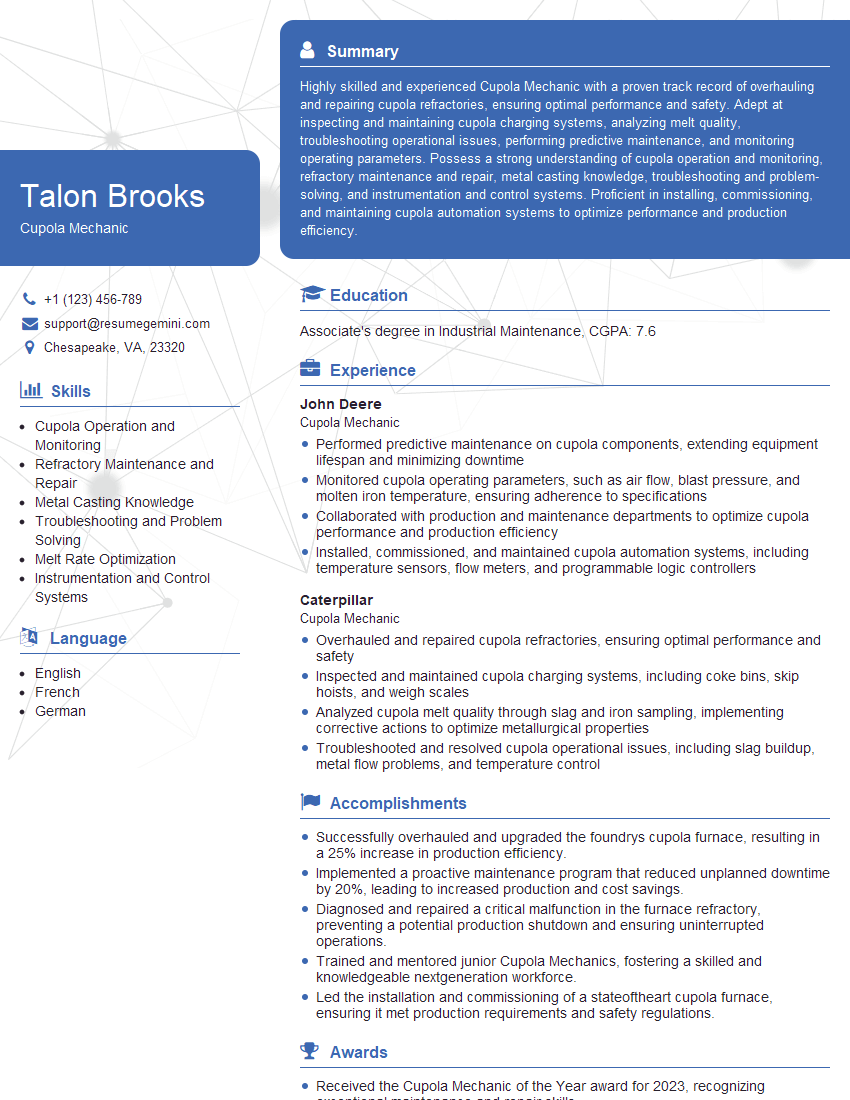

Talon Brooks

Cupola Mechanic

Summary

Highly skilled and experienced Cupola Mechanic with a proven track record of overhauling and repairing cupola refractories, ensuring optimal performance and safety. Adept at inspecting and maintaining cupola charging systems, analyzing melt quality, troubleshooting operational issues, performing predictive maintenance, and monitoring operating parameters. Possess a strong understanding of cupola operation and monitoring, refractory maintenance and repair, metal casting knowledge, troubleshooting and problem-solving, and instrumentation and control systems. Proficient in installing, commissioning, and maintaining cupola automation systems to optimize performance and production efficiency.

Education

Associate’s degree in Industrial Maintenance

March 2017

Skills

- Cupola Operation and Monitoring

- Refractory Maintenance and Repair

- Metal Casting Knowledge

- Troubleshooting and Problem Solving

- Melt Rate Optimization

- Instrumentation and Control Systems

Work Experience

Cupola Mechanic

- Performed predictive maintenance on cupola components, extending equipment lifespan and minimizing downtime

- Monitored cupola operating parameters, such as air flow, blast pressure, and molten iron temperature, ensuring adherence to specifications

- Collaborated with production and maintenance departments to optimize cupola performance and production efficiency

- Installed, commissioned, and maintained cupola automation systems, including temperature sensors, flow meters, and programmable logic controllers

Cupola Mechanic

- Overhauled and repaired cupola refractories, ensuring optimal performance and safety

- Inspected and maintained cupola charging systems, including coke bins, skip hoists, and weigh scales

- Analyzed cupola melt quality through slag and iron sampling, implementing corrective actions to optimize metallurgical properties

- Troubleshooted and resolved cupola operational issues, including slag buildup, metal flow problems, and temperature control

Accomplishments

- Successfully overhauled and upgraded the foundrys cupola furnace, resulting in a 25% increase in production efficiency.

- Implemented a proactive maintenance program that reduced unplanned downtime by 20%, leading to increased production and cost savings.

- Diagnosed and repaired a critical malfunction in the furnace refractory, preventing a potential production shutdown and ensuring uninterrupted operations.

- Trained and mentored junior Cupola Mechanics, fostering a skilled and knowledgeable nextgeneration workforce.

- Led the installation and commissioning of a stateoftheart cupola furnace, ensuring it met production requirements and safety regulations.

Awards

- Received the Cupola Mechanic of the Year award for 2023, recognizing exceptional maintenance and repair skills.

- Recognized as the top Cupola Mechanic in the region for three consecutive years, for demonstrating expertise in furnace operation and maintenance.

- Received the National Cupola Mechanics Associations Safety Excellence Award for maintaining an accidentfree workplace.

- Recognized for developing a groundbreaking method for inspecting and repairing cupola shells, significantly reducing maintenance costs.

Certificates

- Cupola Mechanic Certification

- Foundry Technology Certification

- Metallurgy Certification

- Safety Regulations and Compliance Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cupola Mechanic

- Highlight your experience and skills in cupola operation, maintenance, and repair.

- Quantify your accomplishments with specific numbers and metrics whenever possible.

- Showcase your knowledge of refractory materials and their applications in cupola maintenance.

- Demonstrate your problem-solving abilities and experience in troubleshooting cupola operational issues.

- Emphasize your commitment to safety and adherence to industry standards.

Essential Experience Highlights for a Strong Cupola Mechanic Resume

- Overhauled and repaired cupola refractories to ensure optimal performance and safety.

- Inspected and maintained cupola charging systems, including coke bins, skip hoists, and weigh scales.

- Analyzed cupola melt quality through slag and iron sampling, implementing corrective actions to optimize metallurgical properties.

- Troubleshooted and resolved cupola operational issues, including slag buildup, metal flow problems, and temperature control.

- Performed predictive maintenance on cupola components to extend equipment lifespan and minimize downtime.

- Monitored cupola operating parameters, such as air flow, blast pressure, and molten iron temperature, ensuring adherence to specifications.

- Collaborated with production and maintenance departments to optimize cupola performance and production efficiency.

Frequently Asked Questions (FAQ’s) For Cupola Mechanic

What are the primary responsibilities of a Cupola Mechanic?

Cupola Mechanics are responsible for maintaining and repairing cupolas, which are used to melt iron and other metals. Their duties include inspecting and repairing refractories, maintaining charging systems, analyzing melt quality, troubleshooting operational issues, and performing predictive maintenance.

What qualifications are required to become a Cupola Mechanic?

Typically, Cupola Mechanics have an associate’s degree in Industrial Maintenance or a related field. They also typically have several years of experience working with cupolas and other industrial equipment.

What are the career prospects for Cupola Mechanics?

Cupola Mechanics can advance to supervisory roles or become Maintenance Managers. They may also specialize in a particular area of cupola maintenance, such as refractory repair or instrumentation and control.

What is the work environment of a Cupola Mechanic?

Cupola Mechanics typically work in foundries or other industrial settings. They may be exposed to heat, noise, and fumes, and they may have to work in confined spaces.

What are the safety precautions that Cupola Mechanics must follow?

Cupola Mechanics must follow all safety precautions when working with cupolas. These precautions include wearing appropriate personal protective equipment, following lockout/tagout procedures, and being aware of the potential hazards of working with molten metal.

What are the key skills that Cupola Mechanics need?

Cupola Mechanics need to have strong mechanical skills and be able to work independently. They also need to be able to troubleshoot problems and make repairs quickly and efficiently.

What are the challenges faced by Cupola Mechanics?

Cupola Mechanics face a number of challenges, including working with molten metal, working in confined spaces, and being exposed to heat and noise. They also need to be able to work independently and make quick decisions.

What is the future of the Cupola Mechanic profession?

The future of the Cupola Mechanic profession is expected to be stable. As the demand for metal castings increases, so will the demand for Cupola Mechanics to maintain and repair cupolas.