Are you a seasoned Cupola Melter Helper seeking a new career path? Discover our professionally built Cupola Melter Helper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

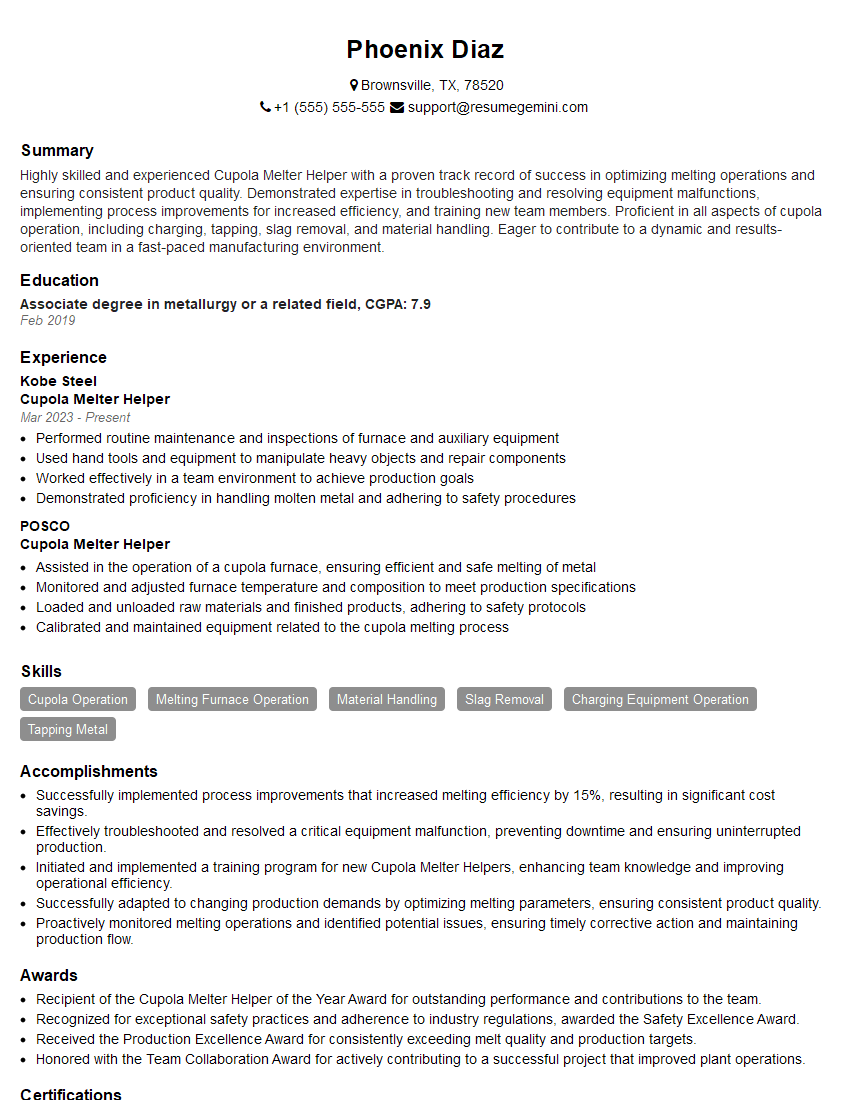

Phoenix Diaz

Cupola Melter Helper

Summary

Highly skilled and experienced Cupola Melter Helper with a proven track record of success in optimizing melting operations and ensuring consistent product quality. Demonstrated expertise in troubleshooting and resolving equipment malfunctions, implementing process improvements for increased efficiency, and training new team members. Proficient in all aspects of cupola operation, including charging, tapping, slag removal, and material handling. Eager to contribute to a dynamic and results-oriented team in a fast-paced manufacturing environment.

Education

Associate degree in metallurgy or a related field

February 2019

Skills

- Cupola Operation

- Melting Furnace Operation

- Material Handling

- Slag Removal

- Charging Equipment Operation

- Tapping Metal

Work Experience

Cupola Melter Helper

- Performed routine maintenance and inspections of furnace and auxiliary equipment

- Used hand tools and equipment to manipulate heavy objects and repair components

- Worked effectively in a team environment to achieve production goals

- Demonstrated proficiency in handling molten metal and adhering to safety procedures

Cupola Melter Helper

- Assisted in the operation of a cupola furnace, ensuring efficient and safe melting of metal

- Monitored and adjusted furnace temperature and composition to meet production specifications

- Loaded and unloaded raw materials and finished products, adhering to safety protocols

- Calibrated and maintained equipment related to the cupola melting process

Accomplishments

- Successfully implemented process improvements that increased melting efficiency by 15%, resulting in significant cost savings.

- Effectively troubleshooted and resolved a critical equipment malfunction, preventing downtime and ensuring uninterrupted production.

- Initiated and implemented a training program for new Cupola Melter Helpers, enhancing team knowledge and improving operational efficiency.

- Successfully adapted to changing production demands by optimizing melting parameters, ensuring consistent product quality.

- Proactively monitored melting operations and identified potential issues, ensuring timely corrective action and maintaining production flow.

Awards

- Recipient of the Cupola Melter Helper of the Year Award for outstanding performance and contributions to the team.

- Recognized for exceptional safety practices and adherence to industry regulations, awarded the Safety Excellence Award.

- Received the Production Excellence Award for consistently exceeding melt quality and production targets.

- Honored with the Team Collaboration Award for actively contributing to a successful project that improved plant operations.

Certificates

- Certified Cupola Melter

- OSHA 30Hour Safety Training

- NFPA 70E Electrical Safety

- American Welding Society (AWS) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cupola Melter Helper

- Highlight your experience in cupola operations, emphasizing your knowledge of charging, tapping, slag removal, and material handling.

- Demonstrate your troubleshooting and problem-solving skills by providing specific examples of equipment malfunctions you have resolved.

- Quantify your accomplishments whenever possible, using metrics to showcase the impact of your process improvements and cost-saving initiatives.

- Emphasize your commitment to safety and adherence to standard operating procedures, highlighting your ability to maintain a clean and organized work environment.

- Showcase your willingness to learn and grow by mentioning your participation in training programs and your eagerness to contribute to continuous improvement initiatives.

Essential Experience Highlights for a Strong Cupola Melter Helper Resume

- Assist the Cupola Melter in all aspects of cupola operations, including charging, tapping, slag removal, and material handling.

- Monitor melting operations and identify potential issues, ensuring timely corrective action and maintaining production flow.

- Troubleshoot and resolve equipment malfunctions and breakdowns, minimizing downtime and ensuring uninterrupted production.

- Optimize melting parameters to adapt to changing production demands and ensure consistent product quality.

- Maintain a clean and organized work area, adhering to safety regulations and standard operating procedures.

- Participate in continuous improvement initiatives and implement process improvements to enhance efficiency and reduce costs.

- Assist in training and mentoring new Cupola Melter Helpers, sharing knowledge and best practices.

Frequently Asked Questions (FAQ’s) For Cupola Melter Helper

What are the primary responsibilities of a Cupola Melter Helper?

Cupola Melter Helpers assist in all aspects of cupola operations, including charging, tapping, slag removal, material handling, and equipment maintenance. They monitor and troubleshoot equipment, optimize melting parameters, and ensure adherence to safety regulations.

What skills are required to be a successful Cupola Melter Helper?

Successful Cupola Melter Helpers typically possess a combination of technical skills, including cupola operation, material handling, and equipment maintenance, as well as problem-solving, communication, and teamwork abilities.

What is the typical work environment for a Cupola Melter Helper?

Cupola Melter Helpers typically work in foundries or manufacturing facilities, operating in high-temperature environments around molten metal and heavy machinery. They must be able to work independently and as part of a team, and adhere to strict safety regulations.

What are the career advancement opportunities for Cupola Melter Helpers?

With experience and additional training, Cupola Melter Helpers can advance to roles such as Cupola Melter, Foundry Supervisor, or Production Manager. They may also specialize in areas such as metallurgy, quality control, or process engineering.

What is the average salary range for Cupola Melter Helpers?

According to industry data, the average salary range for Cupola Melter Helpers can vary depending on experience, location, and company size. However, it typically falls within the range of $25,000 to $50,000 per year.

What are the educational requirements to become a Cupola Melter Helper?

While formal education requirements may vary, many Cupola Melter Helpers hold an associate degree in metallurgy or a related field. Some may also have a high school diploma or equivalent and gain experience through on-the-job training.

What are the key qualities of a successful Cupola Melter Helper?

Successful Cupola Melter Helpers are typically detail-oriented, safety-conscious, and have strong problem-solving and teamwork abilities. They are also physically fit and able to work in a demanding environment.