Are you a seasoned Curing Press Maintainer seeking a new career path? Discover our professionally built Curing Press Maintainer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

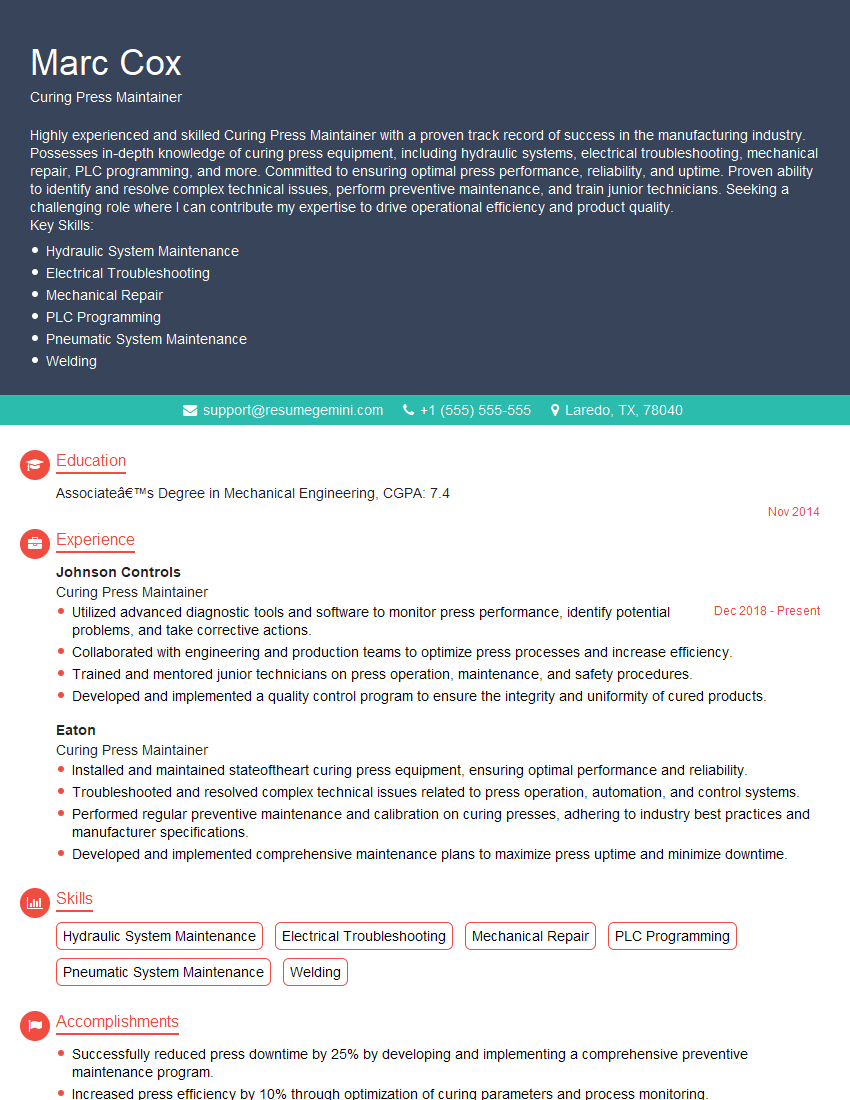

Marc Cox

Curing Press Maintainer

Summary

Highly experienced and skilled Curing Press Maintainer with a proven track record of success in the manufacturing industry. Possesses in-depth knowledge of curing press equipment, including hydraulic systems, electrical troubleshooting, mechanical repair, PLC programming, and more. Committed to ensuring optimal press performance, reliability, and uptime. Proven ability to identify and resolve complex technical issues, perform preventive maintenance, and train junior technicians. Seeking a challenging role where I can contribute my expertise to drive operational efficiency and product quality.

Key Skills:

- Hydraulic System Maintenance

- Electrical Troubleshooting

- Mechanical Repair

- PLC Programming

- Pneumatic System Maintenance

- Welding

Education

Associate’s Degree in Mechanical Engineering

November 2014

Skills

- Hydraulic System Maintenance

- Electrical Troubleshooting

- Mechanical Repair

- PLC Programming

- Pneumatic System Maintenance

- Welding

Work Experience

Curing Press Maintainer

- Utilized advanced diagnostic tools and software to monitor press performance, identify potential problems, and take corrective actions.

- Collaborated with engineering and production teams to optimize press processes and increase efficiency.

- Trained and mentored junior technicians on press operation, maintenance, and safety procedures.

- Developed and implemented a quality control program to ensure the integrity and uniformity of cured products.

Curing Press Maintainer

- Installed and maintained stateoftheart curing press equipment, ensuring optimal performance and reliability.

- Troubleshooted and resolved complex technical issues related to press operation, automation, and control systems.

- Performed regular preventive maintenance and calibration on curing presses, adhering to industry best practices and manufacturer specifications.

- Developed and implemented comprehensive maintenance plans to maximize press uptime and minimize downtime.

Accomplishments

- Successfully reduced press downtime by 25% by developing and implementing a comprehensive preventive maintenance program.

- Increased press efficiency by 10% through optimization of curing parameters and process monitoring.

- Successfully integrated advanced automation systems into the press operation, reducing labor costs and improving consistency.

- Identified and resolved a critical press component failure, preventing a major downtime event.

- Implemented a conditionbased monitoring system for early detection of potential press issues.

Awards

- Recognized for exceptional contributions to improving press uptime by implementing innovative maintenance strategies.

- Received industry recognition for developing a novel approach to press diagnostics and troubleshooting.

- Honored for exceptional safety performance and implementation of best practices in press maintenance.

- Recognized for contributions to the development of new press maintenance standards and guidelines.

Certificates

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Hydraulics Technician (CHT)

- Certified Electrical Technician (CET)

- Certified Mechanical Technician (CMT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Curing Press Maintainer

- Highlight your technical skills and experience: Emphasize your proficiency in hydraulic system maintenance, electrical troubleshooting, mechanical repair, PLC programming, and other relevant technical skills.

- Quantify your accomplishments: Use specific metrics and data to demonstrate the impact of your work, such as reducing downtime, increasing production efficiency, or improving product quality.

- Showcase your problem-solving abilities: Describe instances where you successfully identified and resolved complex technical issues, demonstrating your analytical and critical thinking skills.

- Emphasize your commitment to safety: Highlight your understanding of safety protocols and your experience in implementing and maintaining a safe work environment.

- Demonstrate your teamwork and communication skills: Describe your experience in collaborating with engineering, production, and maintenance teams, effectively communicating technical information, and contributing to a positive work environment.

Essential Experience Highlights for a Strong Curing Press Maintainer Resume

- Installed, maintained, and repaired state-of-the-art curing press equipment to ensure optimal performance and reliability.

- Troubleshooted and resolved complex technical issues related to press operation, automation, and control systems, minimizing downtime and maintaining production efficiency.

- Performed regular preventive maintenance and calibration on curing presses, adhering to industry best practices and manufacturer specifications, to maximize press uptime and product quality.

- Developed and implemented comprehensive maintenance plans to optimize press processes, reduce maintenance costs, and extend equipment lifespan.

- Utilized advanced diagnostic tools and software to monitor press performance, identify potential problems, and take corrective actions, ensuring proactive maintenance and preventing unexpected breakdowns.

- Collaborated with engineering and production teams to optimize press processes and increase efficiency, contributing to overall operational excellence.

- Trained and mentored junior technicians on press operation, maintenance, and safety procedures, ensuring a skilled and knowledgeable workforce.

- Developed and implemented a quality control program to ensure the integrity and uniformity of cured products, meeting customer specifications and industry standards.

Frequently Asked Questions (FAQ’s) For Curing Press Maintainer

What is the primary responsibility of a Curing Press Maintainer?

The primary responsibility of a Curing Press Maintainer is to ensure the optimal performance and reliability of curing press equipment by installing, maintaining, and repairing it, performing preventive maintenance, and troubleshooting and resolving technical issues.

What are the essential technical skills required for this role?

Essential technical skills for a Curing Press Maintainer include hydraulic system maintenance, electrical troubleshooting, mechanical repair, PLC programming, pneumatic system maintenance, and welding.

How can a Curing Press Maintainer contribute to operational efficiency?

By performing regular preventive maintenance, optimizing press processes, and collaborating with engineering and production teams, a Curing Press Maintainer can minimize downtime, reduce maintenance costs, and improve overall production efficiency.

What is the importance of safety in this role?

Safety is paramount for a Curing Press Maintainer. They must have a thorough understanding of safety protocols, be able to identify and mitigate potential hazards, and ensure that the work environment is safe for themselves and others.

How can I enhance my resume for a Curing Press Maintainer position?

To enhance your resume, highlight your technical skills and experience, quantify your accomplishments, showcase your problem-solving abilities, emphasize your commitment to safety, and demonstrate your teamwork and communication skills.

What are the career prospects for a Curing Press Maintainer?

With experience and additional training, a Curing Press Maintainer can advance to roles such as Maintenance Supervisor, Engineering Technician, or Plant Manager.

What are the key qualities of a successful Curing Press Maintainer?

Successful Curing Press Maintainers possess strong technical skills, a commitment to safety, analytical and problem-solving abilities, and effective communication and teamwork skills.

What is the typical work environment for this role?

Curing Press Maintainers typically work in manufacturing facilities, operating and maintaining curing press equipment. The work environment can involve exposure to noise, dust, and chemicals, and may require working in confined spaces or at heights.