Are you a seasoned Curing Press Operator seeking a new career path? Discover our professionally built Curing Press Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

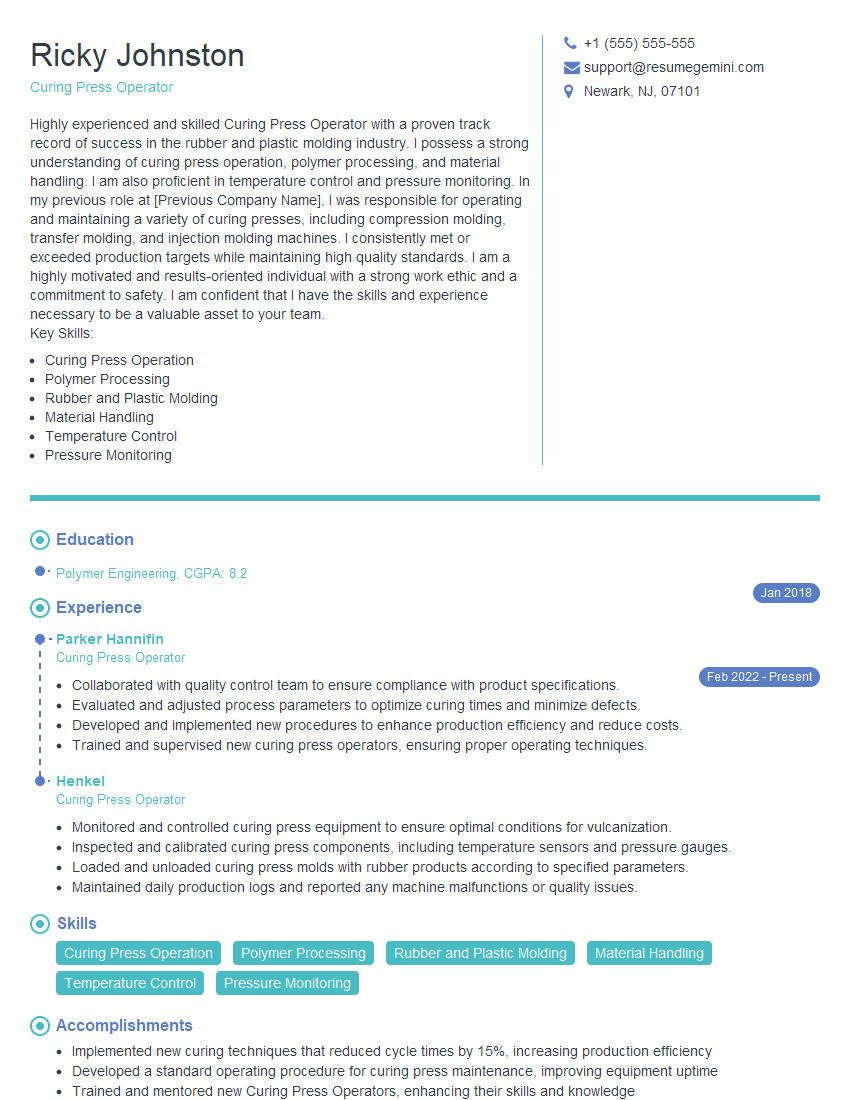

Ricky Johnston

Curing Press Operator

Summary

Highly experienced and skilled Curing Press Operator with a proven track record of success in the rubber and plastic molding industry. I possess a strong understanding of curing press operation, polymer processing, and material handling. I am also proficient in temperature control and pressure monitoring. In my previous role at [Previous Company Name], I was responsible for operating and maintaining a variety of curing presses, including compression molding, transfer molding, and injection molding machines. I consistently met or exceeded production targets while maintaining high quality standards. I am a highly motivated and results-oriented individual with a strong work ethic and a commitment to safety. I am confident that I have the skills and experience necessary to be a valuable asset to your team.

Key Skills:

- Curing Press Operation

- Polymer Processing

- Rubber and Plastic Molding

- Material Handling

- Temperature Control

- Pressure Monitoring

Education

Polymer Engineering

January 2018

Skills

- Curing Press Operation

- Polymer Processing

- Rubber and Plastic Molding

- Material Handling

- Temperature Control

- Pressure Monitoring

Work Experience

Curing Press Operator

- Collaborated with quality control team to ensure compliance with product specifications.

- Evaluated and adjusted process parameters to optimize curing times and minimize defects.

- Developed and implemented new procedures to enhance production efficiency and reduce costs.

- Trained and supervised new curing press operators, ensuring proper operating techniques.

Curing Press Operator

- Monitored and controlled curing press equipment to ensure optimal conditions for vulcanization.

- Inspected and calibrated curing press components, including temperature sensors and pressure gauges.

- Loaded and unloaded curing press molds with rubber products according to specified parameters.

- Maintained daily production logs and reported any machine malfunctions or quality issues.

Accomplishments

- Implemented new curing techniques that reduced cycle times by 15%, increasing production efficiency

- Developed a standard operating procedure for curing press maintenance, improving equipment uptime

- Trained and mentored new Curing Press Operators, enhancing their skills and knowledge

- Developed a quality control system to monitor and maintain consistent curing parameters

- Optimized curing press settings to improve product quality and reduce waste

Awards

- Recognized as Curing Press Operator of the Year for optimizing curing processes

- Received a Silver Safety Award for maintaining a zeroincident work environment

- Recognized for outstanding customer service, receiving numerous positive feedback from clients

- Achieved ISO certification for curing press operations, ensuring adherence to quality standards

Certificates

- Certified Curing Press Operator (CCPO)

- ISO 90012015 Lead Auditor Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Curing Press Operator

Highlight your skills and experience.

Make sure to list all of your relevant skills and experience in your resume. This will help potential employers see why you are qualified for the job.Showcase your knowledge of the industry.

In your resume, be sure to highlight your knowledge of the rubber and plastic molding industry. This will show potential employers that you are familiar with the industry and its standards.Quantify your accomplishments.

When possible, quantify your accomplishments in your resume. This will help potential employers see the impact of your work.Proofread your resume carefully.

Before submitting your resume, proofread it carefully for any errors. This will help you make a good impression on potential employers.

Essential Experience Highlights for a Strong Curing Press Operator Resume

- Operated and maintained a variety of curing presses, including compression molding, transfer molding, and injection molding machines.

- Ensured that all presses were operating within specified temperature and pressure parameters.

- Monitored the curing process to ensure that products met quality standards.

- Loaded and unloaded molds and materials from the presses.

- Performed routine maintenance and repairs on the presses.

- Followed all safety protocols and procedures.

- Worked as part of a team to achieve production goals.

Frequently Asked Questions (FAQ’s) For Curing Press Operator

What is a Curing Press Operator?

A Curing Press Operator is responsible for operating and maintaining curing presses, which are used to mold rubber and plastic products. Curing Press Operators must have a strong understanding of curing press operation, polymer processing, and material handling. They must also be able to monitor temperature and pressure, and perform routine maintenance and repairs on the presses.

What are the qualifications for a Curing Press Operator?

Most Curing Press Operators have a high school diploma or equivalent. Some employers may require candidates to have a degree in polymer engineering or a related field. Curing Press Operators must also have experience operating and maintaining curing presses.

What is the work environment of a Curing Press Operator?

Curing Press Operators typically work in manufacturing facilities. They may be exposed to noise, heat, and chemicals. Curing Press Operators must be able to work independently and as part of a team.

What is the job outlook for Curing Press Operators?

The job outlook for Curing Press Operators is expected to be good over the next few years. The demand for rubber and plastic products is expected to increase, which will lead to increased demand for Curing Press Operators.

What is the average salary for a Curing Press Operator?

The average salary for a Curing Press Operator is around $25,000 per year. However, salaries can vary depending on experience, location, and employer.

What are the benefits of being a Curing Press Operator?

Curing Press Operators can enjoy a number of benefits, including: – Competitive salary and benefits package – Opportunity to work with cutting-edge technology – Chance to make a difference in the manufacturing industry – Stable and secure job outlook

What are the challenges of being a Curing Press Operator?

Curing Press Operators may face a number of challenges, including: – Working in a noisy and hot environment – Exposure to chemicals – Repetitive and physically demanding work – Potential for injuries