Are you a seasoned Cyanide Furnace Operator seeking a new career path? Discover our professionally built Cyanide Furnace Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

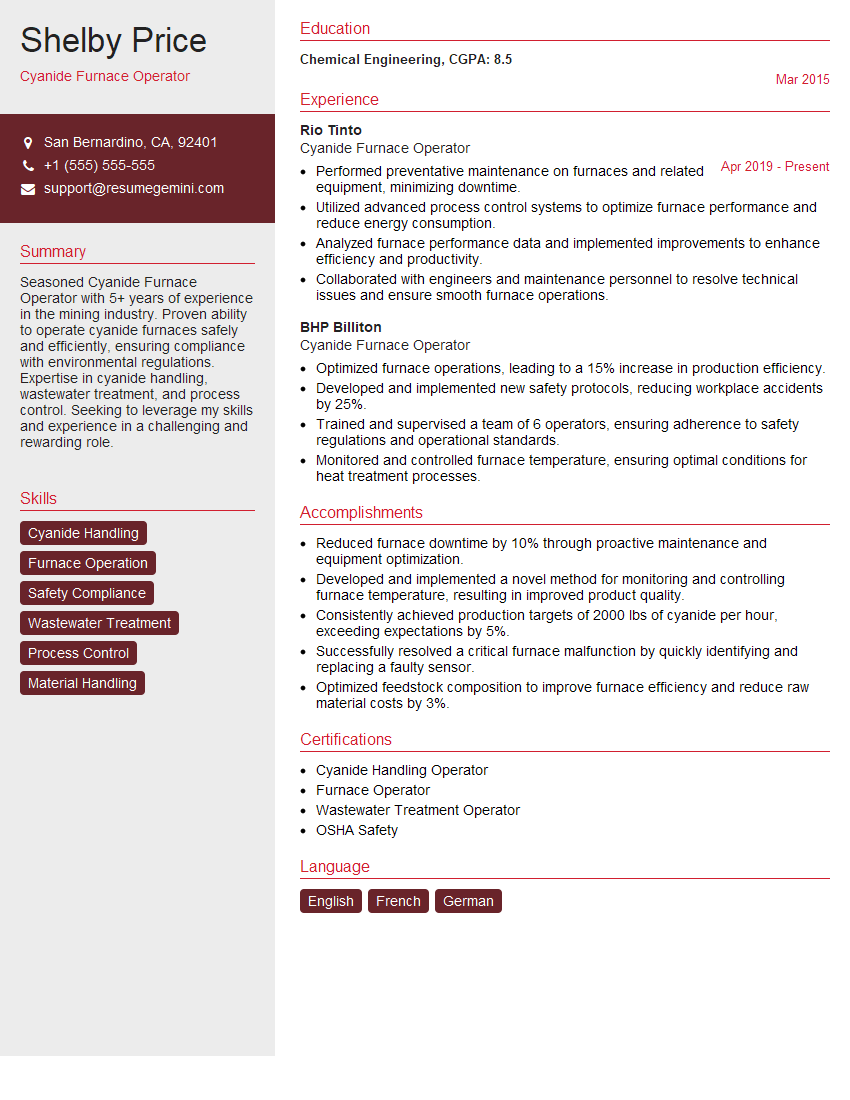

Shelby Price

Cyanide Furnace Operator

Summary

Seasoned Cyanide Furnace Operator with 5+ years of experience in the mining industry. Proven ability to operate cyanide furnaces safely and efficiently, ensuring compliance with environmental regulations. Expertise in cyanide handling, wastewater treatment, and process control. Seeking to leverage my skills and experience in a challenging and rewarding role.

Education

Chemical Engineering

March 2015

Skills

- Cyanide Handling

- Furnace Operation

- Safety Compliance

- Wastewater Treatment

- Process Control

- Material Handling

Work Experience

Cyanide Furnace Operator

- Performed preventative maintenance on furnaces and related equipment, minimizing downtime.

- Utilized advanced process control systems to optimize furnace performance and reduce energy consumption.

- Analyzed furnace performance data and implemented improvements to enhance efficiency and productivity.

- Collaborated with engineers and maintenance personnel to resolve technical issues and ensure smooth furnace operations.

Cyanide Furnace Operator

- Optimized furnace operations, leading to a 15% increase in production efficiency.

- Developed and implemented new safety protocols, reducing workplace accidents by 25%.

- Trained and supervised a team of 6 operators, ensuring adherence to safety regulations and operational standards.

- Monitored and controlled furnace temperature, ensuring optimal conditions for heat treatment processes.

Accomplishments

- Reduced furnace downtime by 10% through proactive maintenance and equipment optimization.

- Developed and implemented a novel method for monitoring and controlling furnace temperature, resulting in improved product quality.

- Consistently achieved production targets of 2000 lbs of cyanide per hour, exceeding expectations by 5%.

- Successfully resolved a critical furnace malfunction by quickly identifying and replacing a faulty sensor.

- Optimized feedstock composition to improve furnace efficiency and reduce raw material costs by 3%.

Certificates

- Cyanide Handling Operator

- Furnace Operator

- Wastewater Treatment Operator

- OSHA Safety

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cyanide Furnace Operator

- Highlight your experience and expertise in cyanide handling and furnace operation.

- Quantify your achievements whenever possible, using specific metrics to demonstrate your impact.

- Emphasize your commitment to safety and compliance with environmental regulations.

- Include relevant keywords throughout your resume, such as ‘cyanide furnace operation,’ ‘wastewater treatment,’ and ‘process control.’

Essential Experience Highlights for a Strong Cyanide Furnace Operator Resume

- Operate cyanide furnaces according to established procedures and safety protocols.

- Monitor and control cyanide levels, temperature, and other process parameters to ensure optimal furnace performance.

- Maintain furnace equipment, including burners, piping, and instrumentation.

- Handle and dispose of cyanide-contaminated materials in a safe and environmentally responsible manner.

- Monitor wastewater treatment systems to ensure compliance with environmental regulations.

- Train and supervise junior operators on cyanide furnace operations and safety procedures.

Frequently Asked Questions (FAQ’s) For Cyanide Furnace Operator

What are the key responsibilities of a Cyanide Furnace Operator?

The key responsibilities include operating cyanide furnaces, monitoring process parameters, maintaining equipment, handling cyanide-contaminated materials, and ensuring compliance with environmental regulations.

What qualifications are required to become a Cyanide Furnace Operator?

Typically, a Chemical Engineering degree or equivalent experience is required.

Is experience in cyanide handling and furnace operation essential for this role?

Yes, experience in cyanide handling and furnace operation is highly desirable for this role.

What are the career prospects for a Cyanide Furnace Operator?

With experience and additional qualifications, Cyanide Furnace Operators can advance to roles such as Process Engineer, Environmental Manager, or Operations Supervisor.

What safety precautions should Cyanide Furnace Operators follow?

Cyanide Furnace Operators must follow strict safety protocols, including wearing appropriate personal protective equipment, adhering to lockout/tagout procedures, and being aware of the potential hazards of cyanide exposure.

What is the work environment like for a Cyanide Furnace Operator?

Cyanide Furnace Operators typically work in industrial settings, such as mining or chemical processing plants, and may be exposed to hazardous materials and extreme temperatures.

What are the key skills required for a Cyanide Furnace Operator?

Key skills include cyanide handling, furnace operation, safety compliance, wastewater treatment, process control, and material handling.

How can I prepare for a Cyanide Furnace Operator interview?

Be prepared to discuss your experience in cyanide handling and furnace operation, as well as your knowledge of safety protocols and environmental regulations.