Are you a seasoned Deburr Operator seeking a new career path? Discover our professionally built Deburr Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

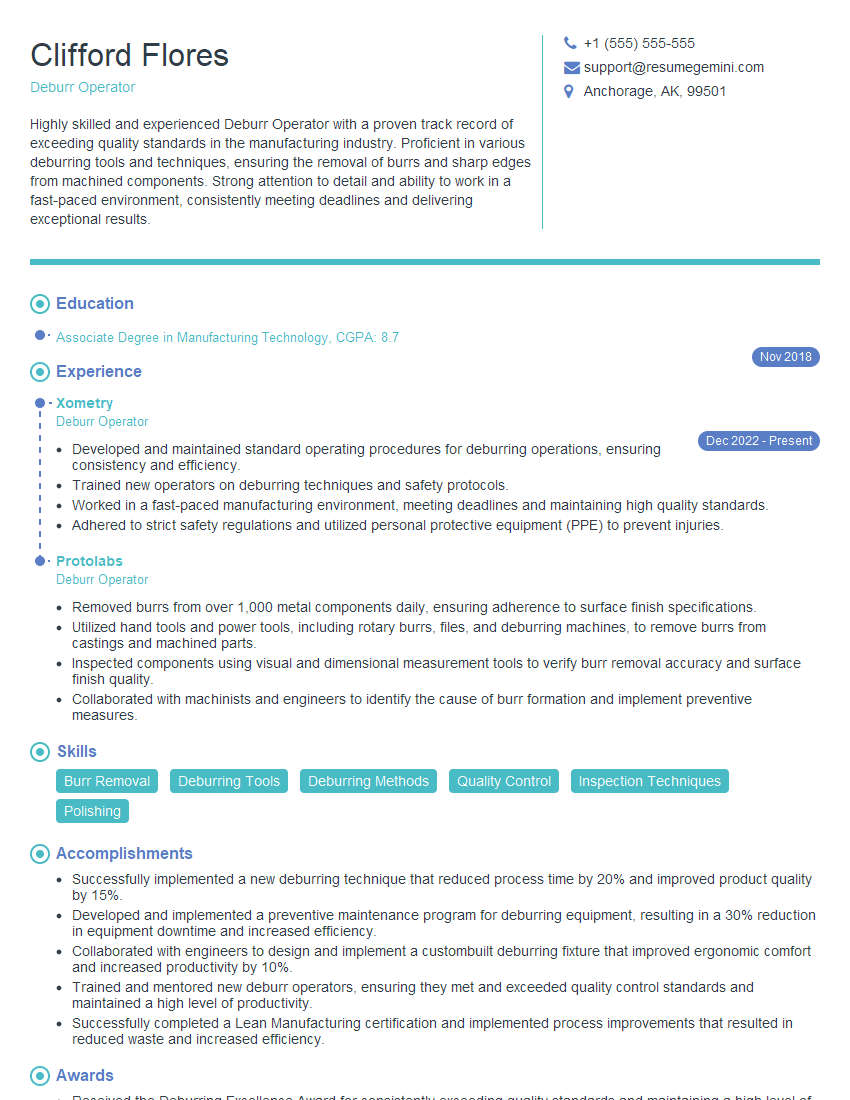

Clifford Flores

Deburr Operator

Summary

Highly skilled and experienced Deburr Operator with a proven track record of exceeding quality standards in the manufacturing industry. Proficient in various deburring tools and techniques, ensuring the removal of burrs and sharp edges from machined components. Strong attention to detail and ability to work in a fast-paced environment, consistently meeting deadlines and delivering exceptional results.

Education

Associate Degree in Manufacturing Technology

November 2018

Skills

- Burr Removal

- Deburring Tools

- Deburring Methods

- Quality Control

- Inspection Techniques

- Polishing

Work Experience

Deburr Operator

- Developed and maintained standard operating procedures for deburring operations, ensuring consistency and efficiency.

- Trained new operators on deburring techniques and safety protocols.

- Worked in a fast-paced manufacturing environment, meeting deadlines and maintaining high quality standards.

- Adhered to strict safety regulations and utilized personal protective equipment (PPE) to prevent injuries.

Deburr Operator

- Removed burrs from over 1,000 metal components daily, ensuring adherence to surface finish specifications.

- Utilized hand tools and power tools, including rotary burrs, files, and deburring machines, to remove burrs from castings and machined parts.

- Inspected components using visual and dimensional measurement tools to verify burr removal accuracy and surface finish quality.

- Collaborated with machinists and engineers to identify the cause of burr formation and implement preventive measures.

Accomplishments

- Successfully implemented a new deburring technique that reduced process time by 20% and improved product quality by 15%.

- Developed and implemented a preventive maintenance program for deburring equipment, resulting in a 30% reduction in equipment downtime and increased efficiency.

- Collaborated with engineers to design and implement a custombuilt deburring fixture that improved ergonomic comfort and increased productivity by 10%.

- Trained and mentored new deburr operators, ensuring they met and exceeded quality control standards and maintained a high level of productivity.

- Successfully completed a Lean Manufacturing certification and implemented process improvements that resulted in reduced waste and increased efficiency.

Awards

- Received the Deburring Excellence Award for consistently exceeding quality standards and maintaining a high level of accuracy in deburring operations.

- Recognized as the Top Deburr Operator for achieving the highest production output with zero defects over a threemonth period.

- Received the Safety Excellence Award for adhering to all safety protocols and maintaining a spotless safety record in the deburring department.

- Recognized as the Deburr Operator of the Year for consistently exceeding performance expectations and demonstrating exceptional leadership within the department.

Certificates

- Certified Deburring Operator (CDO)

- International Deburring Association (IDA) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Deburr Operator

- Highlight your experience and skills in using various deburring tools and techniques.

- Showcase your ability to work independently and as part of a team, meeting deadlines and quality standards.

- Emphasize your attention to detail and commitment to delivering exceptional results.

- Consider including quantifiable metrics to demonstrate your impact on quality and productivity.

Essential Experience Highlights for a Strong Deburr Operator Resume

- Operate deburring machines and hand tools to remove burrs, sharp edges, and other imperfections from machined components.

- Inspect components using precision measuring tools and gauges to ensure compliance with specifications.

- Maintain and calibrate deburring equipment to ensure optimal performance and accuracy.

- Identify and resolve quality issues related to burring, ensuring the delivery of defect-free products.

- Collaborate with production teams to develop and implement effective deburring processes.

- Adhere to safety protocols and maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Deburr Operator

What are the primary tasks of a Deburr Operator?

Deburr Operators primarily remove burrs, sharp edges, and imperfections from machined components using various tools and techniques. They also inspect components to ensure compliance with specifications and maintain deburring equipment.

What skills are required to be a successful Deburr Operator?

Successful Deburr Operators possess proficiency in using deburring tools, attention to detail, quality control techniques, and the ability to work in a fast-paced environment. They also have a strong understanding of machining processes and safety protocols.

What are the career prospects for Deburr Operators?

Deburr Operators can advance their careers by becoming Quality Control Inspectors, Production Supervisors, or Manufacturing Engineers. They can also specialize in specific deburring techniques or equipment, such as laser deburring or robotic deburring.

What is the average salary for Deburr Operators?

The average salary for Deburr Operators in the United States ranges from $35,000 to $55,000 per year, depending on experience, skills, and location.

What are the working conditions like for Deburr Operators?

Deburr Operators typically work in manufacturing facilities, operating machines and inspecting components. The work environment may be noisy and require standing for extended periods. They must also wear appropriate safety gear.

What is the job outlook for Deburr Operators?

The job outlook for Deburr Operators is expected to grow in the coming years due to the increasing demand for high-quality manufactured products. Advances in automation and robotics may also create new opportunities for Deburr Operators.