Are you a seasoned Deflash and Wash Operator seeking a new career path? Discover our professionally built Deflash and Wash Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

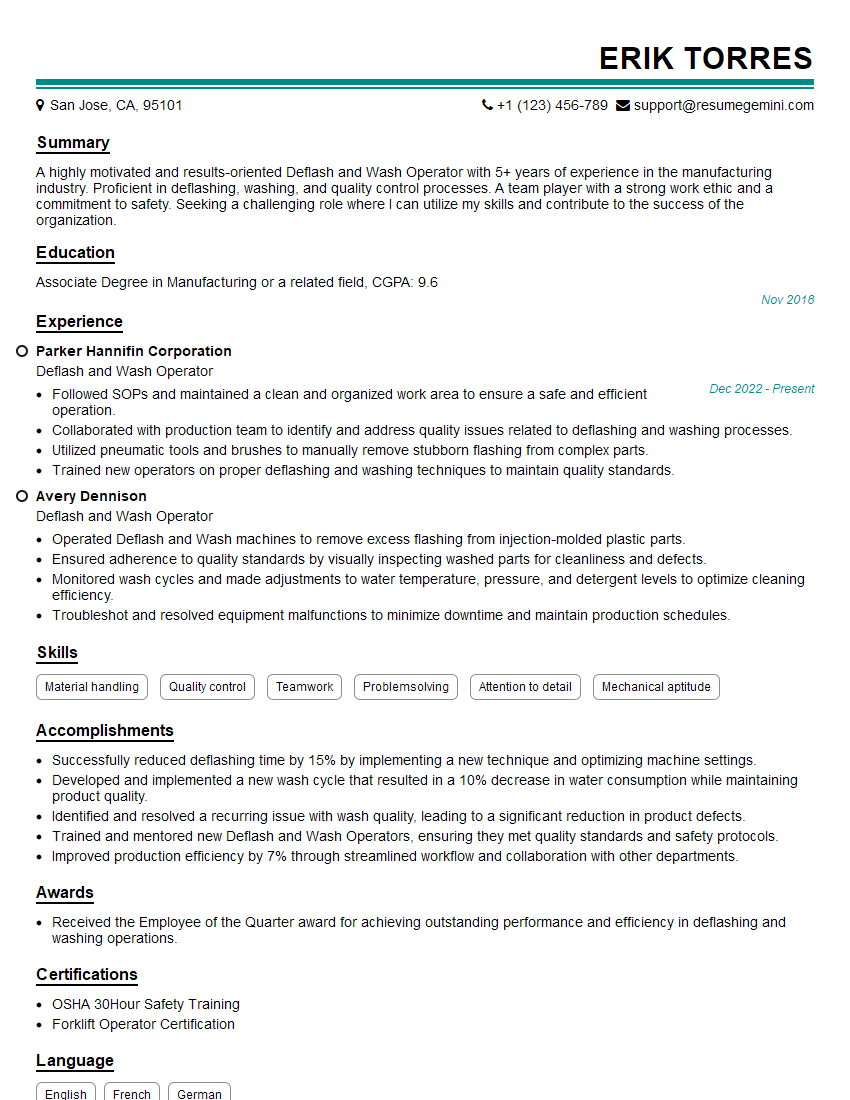

Erik Torres

Deflash and Wash Operator

Summary

A highly motivated and results-oriented Deflash and Wash Operator with 5+ years of experience in the manufacturing industry. Proficient in deflashing, washing, and quality control processes. A team player with a strong work ethic and a commitment to safety. Seeking a challenging role where I can utilize my skills and contribute to the success of the organization.

Education

Associate Degree in Manufacturing or a related field

November 2018

Skills

- Material handling

- Quality control

- Teamwork

- Problemsolving

- Attention to detail

- Mechanical aptitude

Work Experience

Deflash and Wash Operator

- Followed SOPs and maintained a clean and organized work area to ensure a safe and efficient operation.

- Collaborated with production team to identify and address quality issues related to deflashing and washing processes.

- Utilized pneumatic tools and brushes to manually remove stubborn flashing from complex parts.

- Trained new operators on proper deflashing and washing techniques to maintain quality standards.

Deflash and Wash Operator

- Operated Deflash and Wash machines to remove excess flashing from injection-molded plastic parts.

- Ensured adherence to quality standards by visually inspecting washed parts for cleanliness and defects.

- Monitored wash cycles and made adjustments to water temperature, pressure, and detergent levels to optimize cleaning efficiency.

- Troubleshot and resolved equipment malfunctions to minimize downtime and maintain production schedules.

Accomplishments

- Successfully reduced deflashing time by 15% by implementing a new technique and optimizing machine settings.

- Developed and implemented a new wash cycle that resulted in a 10% decrease in water consumption while maintaining product quality.

- Identified and resolved a recurring issue with wash quality, leading to a significant reduction in product defects.

- Trained and mentored new Deflash and Wash Operators, ensuring they met quality standards and safety protocols.

- Improved production efficiency by 7% through streamlined workflow and collaboration with other departments.

Awards

- Received the Employee of the Quarter award for achieving outstanding performance and efficiency in deflashing and washing operations.

Certificates

- OSHA 30Hour Safety Training

- Forklift Operator Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Deflash and Wash Operator

- Highlight your experience in deflashing and washing processes.

- Emphasize your quality control skills and attention to detail.

- Showcase your ability to troubleshoot and resolve issues.

- Quantify your accomplishments with specific metrics whenever possible.

Essential Experience Highlights for a Strong Deflash and Wash Operator Resume

- Deflash molded parts using a variety of tools and techniques.

- Wash and clean parts to remove any remaining flash or debris.

- Inspect parts for quality and identify any defects.

- Troubleshoot and resolve any issues with the deflashing or washing process.

- Maintain a clean and organized work area.

- Adhere to all safety protocols and procedures.

- Work as part of a team to meet production goals.

Frequently Asked Questions (FAQ’s) For Deflash and Wash Operator

What is the role of a Deflash and Wash Operator?

A Deflash and Wash Operator is responsible for removing flash, or excess material, from molded parts using a variety of tools and techniques. They also wash and clean the parts to remove any remaining debris or contaminants.

What are the key skills required for a Deflash and Wash Operator?

The key skills required for a Deflash and Wash Operator include material handling, quality control, teamwork, problem-solving, attention to detail, and mechanical aptitude.

What is the average salary for a Deflash and Wash Operator?

The average salary for a Deflash and Wash Operator varies depending on their experience and location. However, according to Indeed, the average salary for a Deflash and Wash Operator in the United States is $32,000 per year.

What are the career prospects for a Deflash and Wash Operator?

The career prospects for a Deflash and Wash Operator are good. With experience, Deflash and Wash Operators can move into supervisory roles or other positions in the manufacturing industry.

What are the working conditions like for a Deflash and Wash Operator?

Deflash and Wash Operators typically work in a factory setting. The work can be physically demanding and may require standing for long periods of time. However, many companies offer safety equipment and training to help reduce the risk of injuries.