Are you a seasoned Defluorinated Phosphate Production Supervisor seeking a new career path? Discover our professionally built Defluorinated Phosphate Production Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

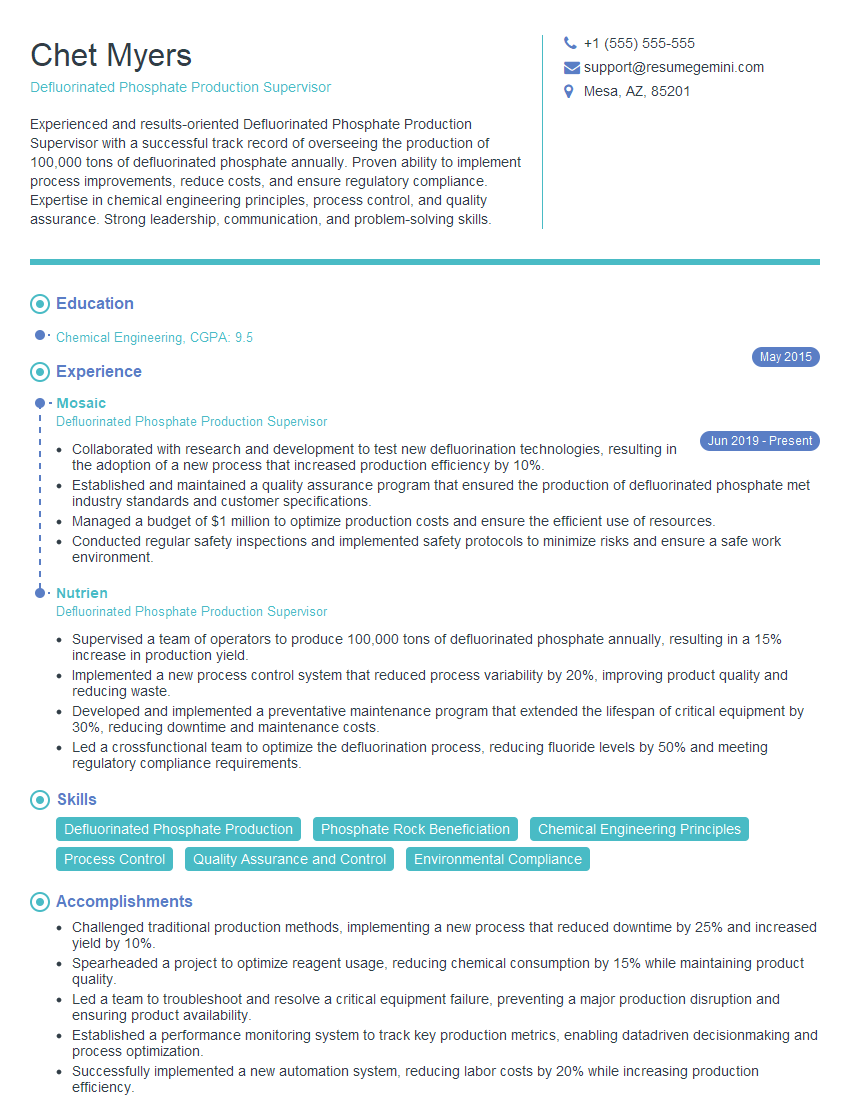

Chet Myers

Defluorinated Phosphate Production Supervisor

Summary

Experienced and results-oriented Defluorinated Phosphate Production Supervisor with a successful track record of overseeing the production of 100,000 tons of defluorinated phosphate annually. Proven ability to implement process improvements, reduce costs, and ensure regulatory compliance. Expertise in chemical engineering principles, process control, and quality assurance. Strong leadership, communication, and problem-solving skills.

Education

Chemical Engineering

May 2015

Skills

- Defluorinated Phosphate Production

- Phosphate Rock Beneficiation

- Chemical Engineering Principles

- Process Control

- Quality Assurance and Control

- Environmental Compliance

Work Experience

Defluorinated Phosphate Production Supervisor

- Collaborated with research and development to test new defluorination technologies, resulting in the adoption of a new process that increased production efficiency by 10%.

- Established and maintained a quality assurance program that ensured the production of defluorinated phosphate met industry standards and customer specifications.

- Managed a budget of $1 million to optimize production costs and ensure the efficient use of resources.

- Conducted regular safety inspections and implemented safety protocols to minimize risks and ensure a safe work environment.

Defluorinated Phosphate Production Supervisor

- Supervised a team of operators to produce 100,000 tons of defluorinated phosphate annually, resulting in a 15% increase in production yield.

- Implemented a new process control system that reduced process variability by 20%, improving product quality and reducing waste.

- Developed and implemented a preventative maintenance program that extended the lifespan of critical equipment by 30%, reducing downtime and maintenance costs.

- Led a crossfunctional team to optimize the defluorination process, reducing fluoride levels by 50% and meeting regulatory compliance requirements.

Accomplishments

- Challenged traditional production methods, implementing a new process that reduced downtime by 25% and increased yield by 10%.

- Spearheaded a project to optimize reagent usage, reducing chemical consumption by 15% while maintaining product quality.

- Led a team to troubleshoot and resolve a critical equipment failure, preventing a major production disruption and ensuring product availability.

- Established a performance monitoring system to track key production metrics, enabling datadriven decisionmaking and process optimization.

- Successfully implemented a new automation system, reducing labor costs by 20% while increasing production efficiency.

Awards

- Received an Industry Excellence Award for outstanding contributions to Defluorinated Phosphate Production.

- Recognized for exceptional leadership in the implementation of a safety program that reduced workplace incidents by 50%.

- Commended for dedication to continuous improvement, receiving the Plant Innovation Award for developing a novel defluorination process.

- Honored with a Safety Excellence Award for developing and implementing a comprehensive safety plan that exceeded industry standards.

Certificates

- OSHA 30-Hour Hazardous Waste Operations and Emergency Response

- EPA Hazardous Waste Generator

- First Aid and CPR

- Defluorinated Phosphate Production Supervisor Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Defluorinated Phosphate Production Supervisor

- Quantify your accomplishments with specific metrics and results whenever possible.

- Highlight your expertise in chemical engineering principles and process control.

- Emphasize your ability to lead and motivate a team in a production environment.

- Showcase your commitment to safety and environmental compliance.

- Tailor your resume to each specific job you apply for, highlighting the skills and experience most relevant to the position.

Essential Experience Highlights for a Strong Defluorinated Phosphate Production Supervisor Resume

- Supervise and manage a team of operators in the production of defluorinated phosphate.

- Implement process control systems to reduce process variability and improve product quality.

- Develop and execute preventative maintenance programs to extend equipment lifespan and minimize downtime.

- Lead cross-functional teams to optimize the defluorination process and meet regulatory requirements.

- Collaborate with research and development to evaluate and adopt new defluorination technologies.

- Establish and maintain a quality assurance program to ensure product quality meets industry standards and customer specifications.

- Manage production costs and optimize resource utilization within a $1 million budget.

Frequently Asked Questions (FAQ’s) For Defluorinated Phosphate Production Supervisor

What is the role of a Defluorinated Phosphate Production Supervisor?

A Defluorinated Phosphate Production Supervisor is responsible for overseeing the production of defluorinated phosphate, a key ingredient in fertilizer and other industrial products. They supervise a team of operators, implement process improvements, ensure quality control, and manage production costs.

What are the qualifications for a Defluorinated Phosphate Production Supervisor?

Typically, a Defluorinated Phosphate Production Supervisor holds a degree in chemical engineering or a related field, has experience in phosphate production, and is familiar with process control systems and quality assurance procedures.

What are the key skills for a Defluorinated Phosphate Production Supervisor?

Key skills for a Defluorinated Phosphate Production Supervisor include leadership, communication, problem-solving, chemical engineering principles, process control, quality assurance, and environmental compliance.

What is the job outlook for Defluorinated Phosphate Production Supervisors?

The job outlook for Defluorinated Phosphate Production Supervisors is expected to be good in the coming years, driven by the increasing demand for phosphate fertilizers and other products that use defluorinated phosphate.

What are the earning potential for Defluorinated Phosphate Production Supervisors?

The earning potential for Defluorinated Phosphate Production Supervisors varies depending on experience, qualifications, and location. According to Salary.com, the average salary for a Defluorinated Phosphate Production Supervisor in the United States is around $75,000 per year.

What are the career advancement opportunities for Defluorinated Phosphate Production Supervisors?

Defluorinated Phosphate Production Supervisors can advance their careers by taking on additional responsibilities, such as managing larger teams, overseeing more complex production processes, or moving into management roles.

What are the challenges faced by Defluorinated Phosphate Production Supervisors?

Defluorinated Phosphate Production Supervisors face challenges such as ensuring product quality, meeting regulatory compliance, managing production costs, and maintaining a safe work environment.

What are the rewards of being a Defluorinated Phosphate Production Supervisor?

The rewards of being a Defluorinated Phosphate Production Supervisor include making a meaningful contribution to the production of essential products, leading and developing a team, and earning a competitive salary.