Are you a seasoned Dehydrogenation Operator seeking a new career path? Discover our professionally built Dehydrogenation Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

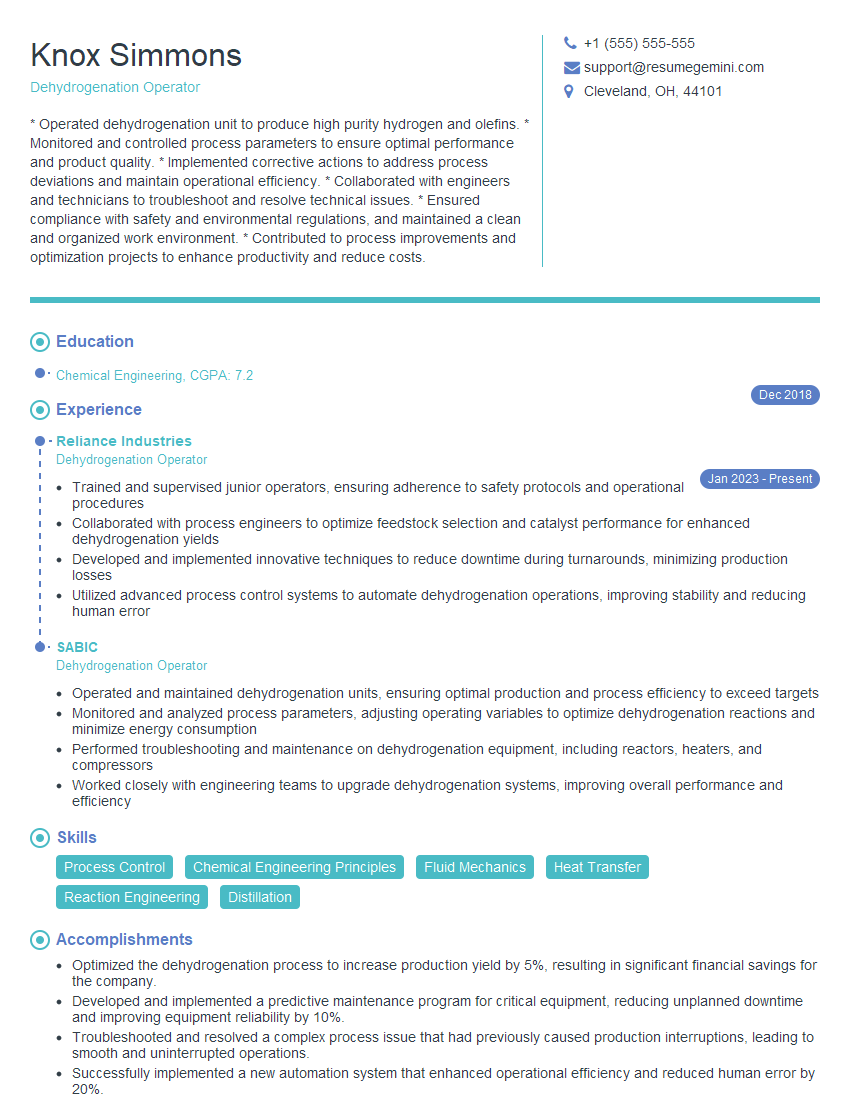

Knox Simmons

Dehydrogenation Operator

Summary

* Operated dehydrogenation unit to produce high purity hydrogen and olefins. * Monitored and controlled process parameters to ensure optimal performance and product quality. * Implemented corrective actions to address process deviations and maintain operational efficiency. * Collaborated with engineers and technicians to troubleshoot and resolve technical issues. * Ensured compliance with safety and environmental regulations, and maintained a clean and organized work environment. * Contributed to process improvements and optimization projects to enhance productivity and reduce costs.

Education

Chemical Engineering

December 2018

Skills

- Process Control

- Chemical Engineering Principles

- Fluid Mechanics

- Heat Transfer

- Reaction Engineering

- Distillation

Work Experience

Dehydrogenation Operator

- Trained and supervised junior operators, ensuring adherence to safety protocols and operational procedures

- Collaborated with process engineers to optimize feedstock selection and catalyst performance for enhanced dehydrogenation yields

- Developed and implemented innovative techniques to reduce downtime during turnarounds, minimizing production losses

- Utilized advanced process control systems to automate dehydrogenation operations, improving stability and reducing human error

Dehydrogenation Operator

- Operated and maintained dehydrogenation units, ensuring optimal production and process efficiency to exceed targets

- Monitored and analyzed process parameters, adjusting operating variables to optimize dehydrogenation reactions and minimize energy consumption

- Performed troubleshooting and maintenance on dehydrogenation equipment, including reactors, heaters, and compressors

- Worked closely with engineering teams to upgrade dehydrogenation systems, improving overall performance and efficiency

Accomplishments

- Optimized the dehydrogenation process to increase production yield by 5%, resulting in significant financial savings for the company.

- Developed and implemented a predictive maintenance program for critical equipment, reducing unplanned downtime and improving equipment reliability by 10%.

- Troubleshooted and resolved a complex process issue that had previously caused production interruptions, leading to smooth and uninterrupted operations.

- Successfully implemented a new automation system that enhanced operational efficiency and reduced human error by 20%.

- Collaborated with engineering team to design and install a new cooling system that improved product quality and reduced energy consumption.

Awards

- Received the Safety Excellence Award for maintaining an outstanding safety record and implementing innovative safety practices throughout the plant.

- Recognized for exceptional performance in operating and maintaining the dehydrogenation unit, ensuring optimal production efficiency.

- Received the Innovation Award for developing a novel catalyst that significantly improved the selectivity and conversion rate in the dehydrogenation process.

- Recognized for exceptional teamwork and collaboration in achieving production targets and maintaining a positive and productive work environment.

Certificates

- Certified Dehydrogenation Operator

- OSHA 40Hour HAZWOPER

- CFR 1910.119 Process Safety Management (PSM)

- ISO 9001 Quality Management System

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Dehydrogenation Operator

- Highlight your experience in operating and controlling dehydrogenation units.

- Quantify your accomplishments with specific metrics, such as increased production output or reduced downtime.

- Demonstrate your knowledge of process control, chemical engineering principles, and safety procedures.

- Emphasize your ability to work independently and as part of a team.

Essential Experience Highlights for a Strong Dehydrogenation Operator Resume

- Operate and monitor dehydrogenation unit to produce hydrogen and olefins.

- Control process parameters such as temperature, pressure, and flow rates to ensure optimal performance.

- Monitor product quality and make adjustments to process parameters as necessary.

- Troubleshoot and resolve process deviations and equipment malfunctions.

- Maintain a clean and safe work environment.

- Follow established safety procedures and comply with environmental regulations.

- Work with engineers and technicians to improve process efficiency and product quality.

Frequently Asked Questions (FAQ’s) For Dehydrogenation Operator

What is the role of a Dehydrogenation Operator?

A Dehydrogenation Operator is responsible for operating and monitoring a dehydrogenation unit to produce hydrogen and olefins. They control process parameters, troubleshoot and resolve equipment issues, and maintain a safe and efficient work environment.

What are the key skills required for a Dehydrogenation Operator?

Key skills include process control, chemical engineering principles, fluid mechanics, heat transfer, reaction engineering, and distillation.

What is the educational background required for a Dehydrogenation Operator?

A bachelor’s degree in chemical engineering is typically required.

What are the career prospects for a Dehydrogenation Operator?

Dehydrogenation Operators can advance to positions such as Production Supervisor, Process Engineer, or Plant Manager.

What is the average salary for a Dehydrogenation Operator?

The average salary for a Dehydrogenation Operator in the United States is around $75,000 per year.

What are the working conditions for a Dehydrogenation Operator?

Dehydrogenation Operators typically work in a plant environment, where they may be exposed to noise, heat, and chemicals. They must be able to work independently and as part of a team.