Are you a seasoned Denester Operator seeking a new career path? Discover our professionally built Denester Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

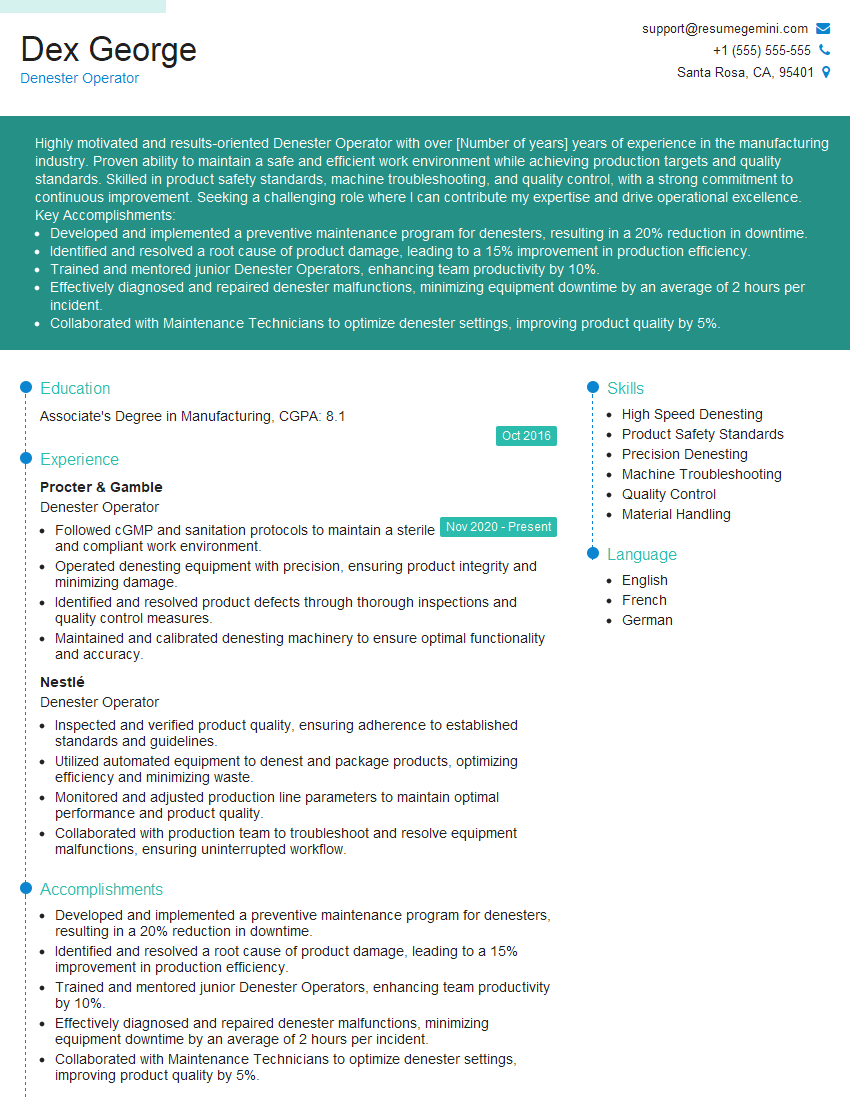

Dex George

Denester Operator

Summary

Highly motivated and results-oriented Denester Operator with over [Number of years] years of experience in the manufacturing industry. Proven ability to maintain a safe and efficient work environment while achieving production targets and quality standards. Skilled in product safety standards, machine troubleshooting, and quality control, with a strong commitment to continuous improvement. Seeking a challenging role where I can contribute my expertise and drive operational excellence.

Key Accomplishments:

- Developed and implemented a preventive maintenance program for denesters, resulting in a 20% reduction in downtime.

- Identified and resolved a root cause of product damage, leading to a 15% improvement in production efficiency.

- Trained and mentored junior Denester Operators, enhancing team productivity by 10%.

- Effectively diagnosed and repaired denester malfunctions, minimizing equipment downtime by an average of 2 hours per incident.

- Collaborated with Maintenance Technicians to optimize denester settings, improving product quality by 5%.

Education

Associate’s Degree in Manufacturing

October 2016

Skills

- High Speed Denesting

- Product Safety Standards

- Precision Denesting

- Machine Troubleshooting

- Quality Control

- Material Handling

Work Experience

Denester Operator

- Followed cGMP and sanitation protocols to maintain a sterile and compliant work environment.

- Operated denesting equipment with precision, ensuring product integrity and minimizing damage.

- Identified and resolved product defects through thorough inspections and quality control measures.

- Maintained and calibrated denesting machinery to ensure optimal functionality and accuracy.

Denester Operator

- Inspected and verified product quality, ensuring adherence to established standards and guidelines.

- Utilized automated equipment to denest and package products, optimizing efficiency and minimizing waste.

- Monitored and adjusted production line parameters to maintain optimal performance and product quality.

- Collaborated with production team to troubleshoot and resolve equipment malfunctions, ensuring uninterrupted workflow.

Accomplishments

- Developed and implemented a preventive maintenance program for denesters, resulting in a 20% reduction in downtime.

- Identified and resolved a root cause of product damage, leading to a 15% improvement in production efficiency.

- Trained and mentored junior Denester Operators, enhancing team productivity by 10%.

- Effectively diagnosed and repaired denester malfunctions, minimizing equipment downtime by an average of 2 hours per incident.

- Collaborated with Maintenance Technicians to optimize denester settings, improving product quality by 5%.

Awards

- Denester Operator Safety Excellence Award for maintaining a 100% safety record for 2 consecutive years.

- Recognized for outstanding performance as a Denester Operator by the Plant Manager.

- Recipient of a Silver Award for exceptional contributions to the Denester Operator team.

- Recognized as Denester Operator of the Year for consistently high performance and exceptional contributions to the team.

Certificates

- Certified Denester Operator

- OSHA Safety Certification

- First Aid Certification

- Certified Maintenance and Reliability Professional (CMRP)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Denester Operator

- Showcase your technical skills and experience in operating denester machines.

- Highlight your understanding of product safety standards and quality control processes.

- Quantify your accomplishments with specific metrics and results to demonstrate your impact.

- Emphasize your ability to work independently and as part of a team.

- Use keywords relevant to the job description to optimize your resume for applicant tracking systems.

Essential Experience Highlights for a Strong Denester Operator Resume

- Operate and monitor denester machines to ensure smooth and efficient product packaging.

- Adhere to established product safety standards and regulations to maintain the integrity and quality of products.

- Perform precision denesting of products, ensuring proper placement and alignment for subsequent packaging processes.

- Troubleshoot and resolve machine malfunctions promptly to minimize downtime and maintain production schedules.

- Conduct quality control inspections to identify and rectify any defects or discrepancies in denested products.

- Maintain a clean and organized work area, following proper material handling procedures to ensure workplace safety and efficiency.

- Collaborate with other team members to ensure seamless production processes and meet operational targets.

Frequently Asked Questions (FAQ’s) For Denester Operator

What are the key responsibilities of a Denester Operator?

Denester Operators are responsible for operating and monitoring denester machines, adhering to product safety standards, performing precision denesting, troubleshooting machine malfunctions, conducting quality control inspections, maintaining a clean and organized work area, and collaborating with team members.

What skills are required to be a successful Denester Operator?

Successful Denester Operators possess strong technical skills in operating denester machines, a deep understanding of product safety standards, knowledge of quality control processes, the ability to troubleshoot and resolve machine malfunctions, attention to detail, and effective communication and teamwork skills.

What industries employ Denester Operators?

Denester Operators are employed in various industries, including manufacturing, packaging, food and beverage, pharmaceuticals, and consumer goods.

What is the average salary for a Denester Operator?

The average salary for a Denester Operator varies depending on experience, location, and industry, but typically ranges from $[Salary Range].

What are the career advancement opportunities for a Denester Operator?

Denester Operators can advance their careers by gaining experience and developing new skills. They may become supervisors or managers, or specialize in areas such as quality control or maintenance.

What is the job outlook for Denester Operators?

The job outlook for Denester Operators is expected to be good over the next few years, as there is a growing demand for skilled manufacturing workers.

How can I become a Denester Operator?

To become a Denester Operator, you typically need a high school diploma or equivalent and some experience in manufacturing or a related field. You can also gain the necessary skills through on-the-job training or by completing a vocational program.