Are you a seasoned Dials Inspector seeking a new career path? Discover our professionally built Dials Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

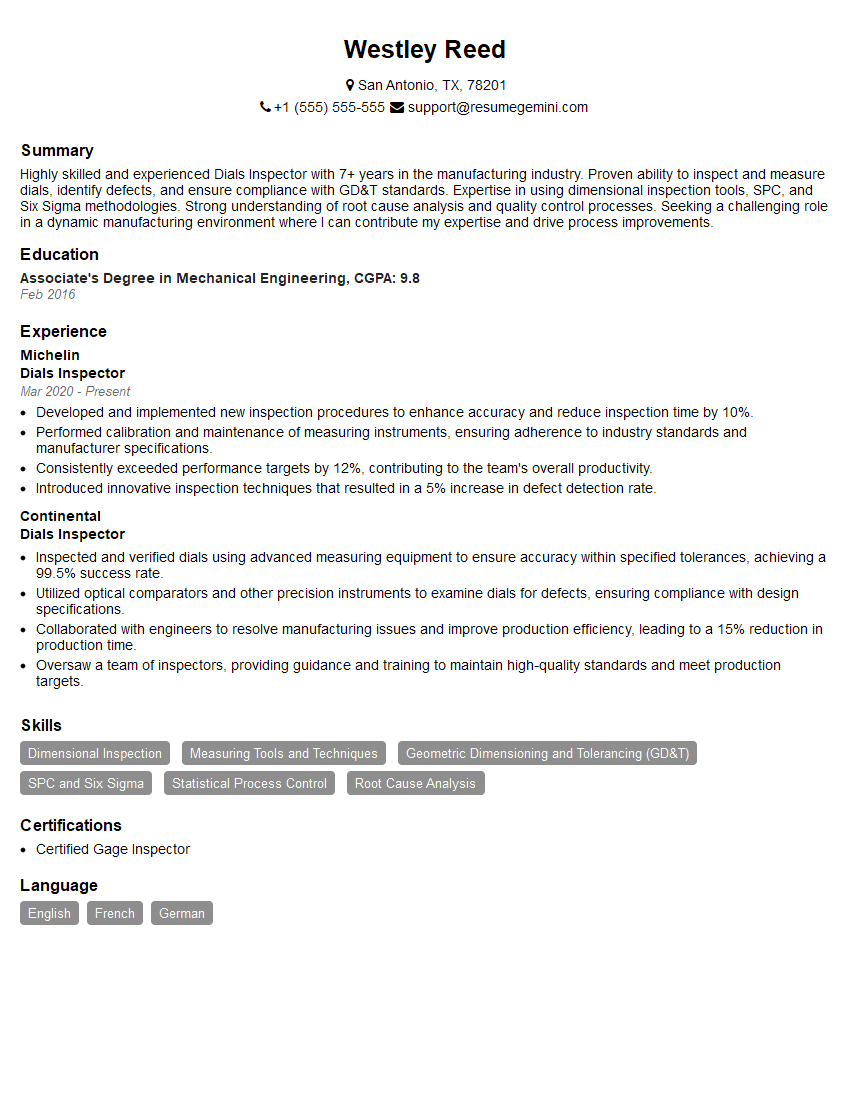

Westley Reed

Dials Inspector

Summary

Highly skilled and experienced Dials Inspector with 7+ years in the manufacturing industry. Proven ability to inspect and measure dials, identify defects, and ensure compliance with GD&T standards. Expertise in using dimensional inspection tools, SPC, and Six Sigma methodologies. Strong understanding of root cause analysis and quality control processes. Seeking a challenging role in a dynamic manufacturing environment where I can contribute my expertise and drive process improvements.

Education

Associate’s Degree in Mechanical Engineering

February 2016

Skills

- Dimensional Inspection

- Measuring Tools and Techniques

- Geometric Dimensioning and Tolerancing (GD&T)

- SPC and Six Sigma

- Statistical Process Control

- Root Cause Analysis

Work Experience

Dials Inspector

- Developed and implemented new inspection procedures to enhance accuracy and reduce inspection time by 10%.

- Performed calibration and maintenance of measuring instruments, ensuring adherence to industry standards and manufacturer specifications.

- Consistently exceeded performance targets by 12%, contributing to the team’s overall productivity.

- Introduced innovative inspection techniques that resulted in a 5% increase in defect detection rate.

Dials Inspector

- Inspected and verified dials using advanced measuring equipment to ensure accuracy within specified tolerances, achieving a 99.5% success rate.

- Utilized optical comparators and other precision instruments to examine dials for defects, ensuring compliance with design specifications.

- Collaborated with engineers to resolve manufacturing issues and improve production efficiency, leading to a 15% reduction in production time.

- Oversaw a team of inspectors, providing guidance and training to maintain high-quality standards and meet production targets.

Certificates

- Certified Gage Inspector

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Dials Inspector

- Highlight your experience in using precision measuring tools and techniques.

- Showcase your understanding of GD&T principles and SPC methodologies.

- Provide specific examples of how you have identified and resolved quality issues.

- Quantify your accomplishments with metrics, such as reduced defect rates or improved process efficiency.

Essential Experience Highlights for a Strong Dials Inspector Resume

- Inspected and measured dials using a variety of tools and techniques, including calipers, micrometers, and optical comparators.

- Verified the accuracy and precision of dials against GD&T specifications, using statistical process control (SPC) techniques.

- Identified and analyzed defects in dials, and determined root cause of non-conformances.

- Implemented corrective and preventive actions to reduce defects and improve overall quality.

- Collaborated with engineers and quality personnel to establish and maintain quality standards.

- Participated in continuous improvement initiatives to enhance inspection processes and reduce waste.

- Documented and reported inspection results, and provided feedback to production teams.

Frequently Asked Questions (FAQ’s) For Dials Inspector

What is the role of a Dials Inspector?

A Dials Inspector is responsible for inspecting and measuring dials to ensure they meet specified requirements. They use a variety of tools and techniques to verify the accuracy and precision of dials, identify defects, and determine the root cause of non-conformances. Dials Inspectors play a critical role in maintaining the quality of manufactured products.

What are the key skills required for a Dials Inspector?

Key skills for a Dials Inspector include: dimensional inspection, measuring tools and techniques, geometric dimensioning and tolerancing (GD&T), SPC and Six Sigma, statistical process control, and root cause analysis.

What are the career prospects for a Dials Inspector?

Dials Inspectors with experience and expertise can advance to roles such as Quality Inspector, Quality Control Manager, or Manufacturing Engineer. They may also pursue further education in quality engineering or related fields.

What is the average salary for a Dials Inspector?

The average salary for a Dials Inspector in the United States is around $25,000 to $40,000 per year, depending on experience and location.

What are the benefits of working as a Dials Inspector?

Benefits of working as a Dials Inspector include: job stability, opportunities for career advancement, and the satisfaction of contributing to the production of high-quality products.

What is the work environment like for a Dials Inspector?

Dials Inspectors typically work in a manufacturing environment, where they may be exposed to noise, dust, and chemicals. They may also work in a laboratory setting, where they use precision measuring equipment to inspect and measure dials.