Are you a seasoned Die-Casting and Plastic Molding Mold Maker seeking a new career path? Discover our professionally built Die-Casting and Plastic Molding Mold Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

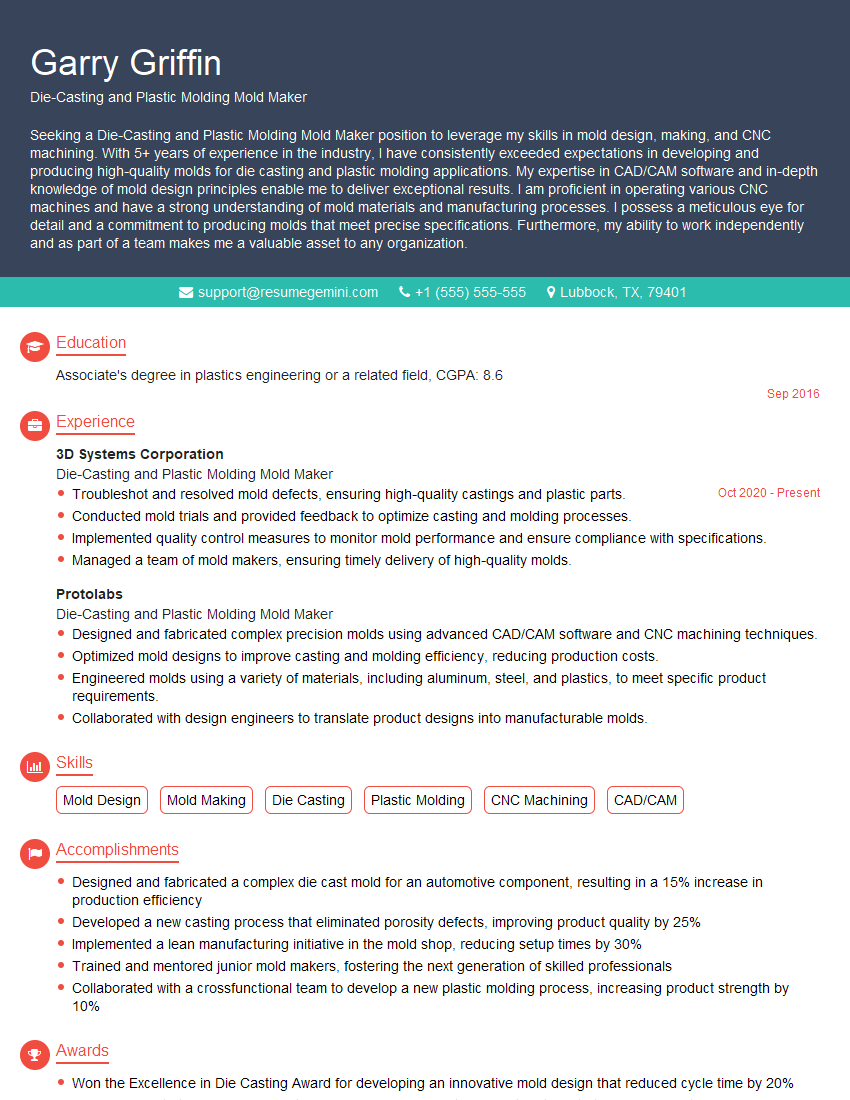

Garry Griffin

Die-Casting and Plastic Molding Mold Maker

Summary

Seeking a Die-Casting and Plastic Molding Mold Maker position to leverage my skills in mold design, making, and CNC machining. With 5+ years of experience in the industry, I have consistently exceeded expectations in developing and producing high-quality molds for die casting and plastic molding applications. My expertise in CAD/CAM software and in-depth knowledge of mold design principles enable me to deliver exceptional results. I am proficient in operating various CNC machines and have a strong understanding of mold materials and manufacturing processes. I possess a meticulous eye for detail and a commitment to producing molds that meet precise specifications. Furthermore, my ability to work independently and as part of a team makes me a valuable asset to any organization.

Education

Associate’s degree in plastics engineering or a related field

September 2016

Skills

- Mold Design

- Mold Making

- Die Casting

- Plastic Molding

- CNC Machining

- CAD/CAM

Work Experience

Die-Casting and Plastic Molding Mold Maker

- Troubleshot and resolved mold defects, ensuring high-quality castings and plastic parts.

- Conducted mold trials and provided feedback to optimize casting and molding processes.

- Implemented quality control measures to monitor mold performance and ensure compliance with specifications.

- Managed a team of mold makers, ensuring timely delivery of high-quality molds.

Die-Casting and Plastic Molding Mold Maker

- Designed and fabricated complex precision molds using advanced CAD/CAM software and CNC machining techniques.

- Optimized mold designs to improve casting and molding efficiency, reducing production costs.

- Engineered molds using a variety of materials, including aluminum, steel, and plastics, to meet specific product requirements.

- Collaborated with design engineers to translate product designs into manufacturable molds.

Accomplishments

- Designed and fabricated a complex die cast mold for an automotive component, resulting in a 15% increase in production efficiency

- Developed a new casting process that eliminated porosity defects, improving product quality by 25%

- Implemented a lean manufacturing initiative in the mold shop, reducing setup times by 30%

- Trained and mentored junior mold makers, fostering the next generation of skilled professionals

- Collaborated with a crossfunctional team to develop a new plastic molding process, increasing product strength by 10%

Awards

- Won the Excellence in Die Casting Award for developing an innovative mold design that reduced cycle time by 20%

- Recognized with the Mold Maker of the Year Award for exceptional contributions to the field of plastic molding

- Received the National Die Casting Associations Award for Technical Achievement for a breakthrough in casting technology

- Honored with the Safety Excellence Award for maintaining a spotless safety record throughout a challenging project

Certificates

- Certified Mold Maker (CMM)

- Certified Die Casting Technician (CDCT)

- ISO 9001:2015

- ASME B46.1

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Die-Casting and Plastic Molding Mold Maker

- Highlight your experience and skills in mold design and making, emphasizing your ability to create high-quality molds that meet specific requirements.

- Showcase your proficiency in CAD/CAM software and your understanding of mold design principles.

- Emphasize your experience in operating CNC machines and your knowledge of mold materials and manufacturing processes.

- Highlight your ability to work independently and as part of a team.

- Quantify your accomplishments whenever possible to demonstrate the impact of your work.

Essential Experience Highlights for a Strong Die-Casting and Plastic Molding Mold Maker Resume

- Designing and developing molds for die casting and plastic molding processes.

- Analyzing customer requirements and translating them into detailed mold designs.

- Selecting appropriate mold materials and manufacturing techniques based on product specifications.

- Operating CNC machines to create mold components with precision and accuracy.

- Performing quality control inspections to ensure molds meet design specifications.

- Troubleshooting and resolving any issues that arise during the mold-making process.

Frequently Asked Questions (FAQ’s) For Die-Casting and Plastic Molding Mold Maker

What are the primary responsibilities of a Die-Casting and Plastic Molding Mold Maker?

Die-Casting and Plastic Molding Mold Makers are responsible for designing, developing, and producing molds used in die casting and plastic molding processes. Their key responsibilities include analyzing customer requirements, selecting appropriate mold materials and manufacturing techniques, operating CNC machines to create mold components, performing quality control inspections, and troubleshooting any issues that arise during the mold-making process.

What skills and qualifications are required to become a Die-Casting and Plastic Molding Mold Maker?

To become a Die-Casting and Plastic Molding Mold Maker, individuals typically need an associate’s degree in plastics engineering or a related field, along with experience in mold design, making, and CNC machining. Proficiency in CAD/CAM software and a strong understanding of mold design principles are also essential.

What are the career opportunities for Die-Casting and Plastic Molding Mold Makers?

Die-Casting and Plastic Molding Mold Makers can find employment in various industries, including automotive, aerospace, medical, and consumer products. They may work for mold-making companies, manufacturing firms, or research and development organizations.

What is the job outlook for Die-Casting and Plastic Molding Mold Makers?

The job outlook for Die-Casting and Plastic Molding Mold Makers is expected to be positive in the coming years due to the increasing demand for molds in various industries.

What are the earning prospects for Die-Casting and Plastic Molding Mold Makers?

The earning prospects for Die-Casting and Plastic Molding Mold Makers can vary depending on their experience, skills, and location. According to the U.S. Bureau of Labor Statistics, the median annual salary for Mold Makers and Patternmakers was $48,860 in May 2021.