Are you a seasoned Die Finisher seeking a new career path? Discover our professionally built Die Finisher Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

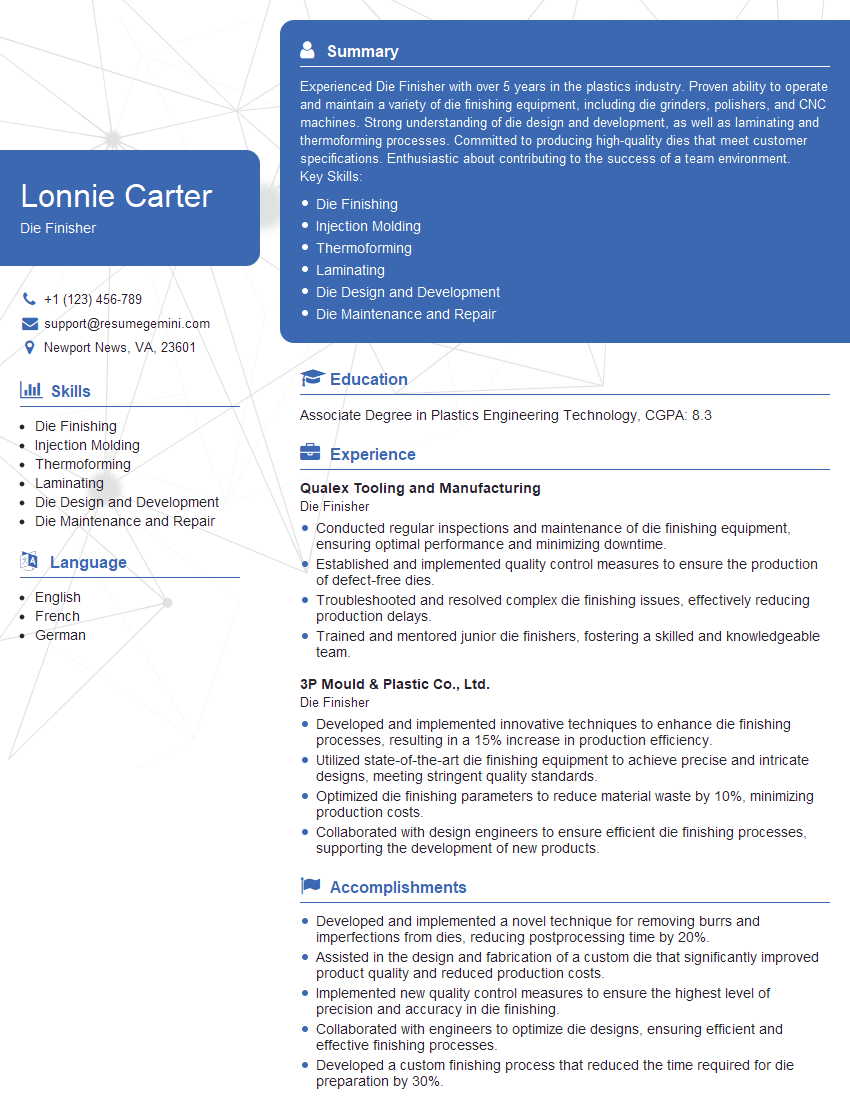

Lonnie Carter

Die Finisher

Summary

Experienced Die Finisher with over 5 years in the plastics industry. Proven ability to operate and maintain a variety of die finishing equipment, including die grinders, polishers, and CNC machines. Strong understanding of die design and development, as well as laminating and thermoforming processes. Committed to producing high-quality dies that meet customer specifications. Enthusiastic about contributing to the success of a team environment.

Key Skills:

- Die Finishing

- Injection Molding

- Thermoforming

- Laminating

- Die Design and Development

- Die Maintenance and Repair

Education

Associate Degree in Plastics Engineering Technology

December 2014

Skills

- Die Finishing

- Injection Molding

- Thermoforming

- Laminating

- Die Design and Development

- Die Maintenance and Repair

Work Experience

Die Finisher

- Conducted regular inspections and maintenance of die finishing equipment, ensuring optimal performance and minimizing downtime.

- Established and implemented quality control measures to ensure the production of defect-free dies.

- Troubleshooted and resolved complex die finishing issues, effectively reducing production delays.

- Trained and mentored junior die finishers, fostering a skilled and knowledgeable team.

Die Finisher

- Developed and implemented innovative techniques to enhance die finishing processes, resulting in a 15% increase in production efficiency.

- Utilized state-of-the-art die finishing equipment to achieve precise and intricate designs, meeting stringent quality standards.

- Optimized die finishing parameters to reduce material waste by 10%, minimizing production costs.

- Collaborated with design engineers to ensure efficient die finishing processes, supporting the development of new products.

Accomplishments

- Developed and implemented a novel technique for removing burrs and imperfections from dies, reducing postprocessing time by 20%.

- Assisted in the design and fabrication of a custom die that significantly improved product quality and reduced production costs.

- Implemented new quality control measures to ensure the highest level of precision and accuracy in die finishing.

- Collaborated with engineers to optimize die designs, ensuring efficient and effective finishing processes.

- Developed a custom finishing process that reduced the time required for die preparation by 30%.

Awards

- Recognized for exceptional performance in optimizing die finishing processes, resulting in a 15% increase in production efficiency.

- Received the Die Finisher of the Year award for consistently exceeding quality standards and meeting tight deadlines.

- Recognized for developing a training program that improved the skills and knowledge of junior Die Finishers.

- Received the Safety Excellence Award for maintaining an exceptional safety record and implementing proactive safety measures.

Certificates

- Certified Tool and Die Maker (CTDM)

- Society of Plastics Engineers (SPE) Certification

- ISO 9001 Lead Auditor Certification

- APQP and PPAP Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Die Finisher

- Highlight your experience in die finishing, including the specific equipment you have operated.

- Quantify your accomplishments whenever possible, using specific numbers and metrics.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

- Proofread your resume carefully before submitting it, and ask a friend or family member to review it as well.

Essential Experience Highlights for a Strong Die Finisher Resume

- Operate and maintain a variety of die finishing equipment, including die grinders, polishers, and CNC machines.

- Inspect dies to ensure they meet customer specifications.

- Troubleshoot and repair dies as needed.

- Assist in the design and development of new dies.

- Train new employees on die finishing techniques.

- Maintain a clean and organized work area.

- Follow all safety procedures.

Frequently Asked Questions (FAQ’s) For Die Finisher

What is a Die Finisher?

A Die Finisher is responsible for the finishing and maintenance of dies used in the plastics industry. This includes operating and maintaining a variety of die finishing equipment, inspecting dies to ensure they meet customer specifications, troubleshooting and repairing dies as needed, and assisting in the design and development of new dies.

What are the key skills required for a Die Finisher?

The key skills required for a Die Finisher include die finishing, injection molding, thermoforming, laminating, die design and development, and die maintenance and repair.

What is the work environment of a Die Finisher?

Die Finishers typically work in a manufacturing environment, operating and maintaining die finishing equipment. They may also work with other members of the production team, such as engineers and mold makers.

What is the career outlook for Die Finishers?

The career outlook for Die Finishers is expected to be good over the next few years. As the plastics industry continues to grow, there will be a need for skilled Die Finishers to operate and maintain the equipment used to produce plastic products.

What are the salary expectations for Die Finishers?

The salary expectations for Die Finishers vary depending on their experience, skills, and location. However, the average salary for Die Finishers is around $25 per hour.

What are the educational requirements for Die Finishers?

Die Finishers typically have an associate’s degree in plastics engineering technology or a related field. However, some employers may hire Die Finishers with a high school diploma or equivalent experience.

What are the certification requirements for Die Finishers?

There are no specific certification requirements for Die Finishers. However, some employers may prefer to hire Die Finishers who have completed a certification program in die finishing or a related field.