Are you a seasoned Die Hardener seeking a new career path? Discover our professionally built Die Hardener Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

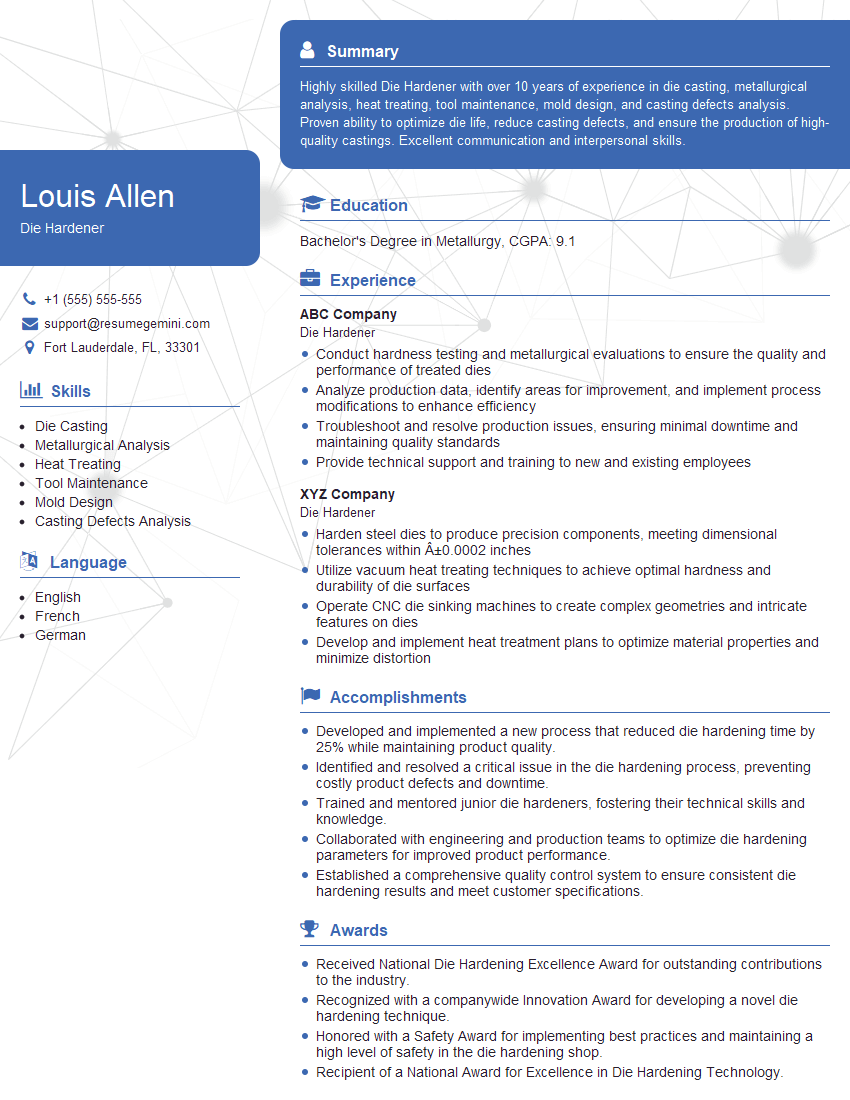

Louis Allen

Die Hardener

Summary

Highly skilled Die Hardener with over 10 years of experience in die casting, metallurgical analysis, heat treating, tool maintenance, mold design, and casting defects analysis. Proven ability to optimize die life, reduce casting defects, and ensure the production of high-quality castings. Excellent communication and interpersonal skills.

Education

Bachelor’s Degree in Metallurgy

September 2018

Skills

- Die Casting

- Metallurgical Analysis

- Heat Treating

- Tool Maintenance

- Mold Design

- Casting Defects Analysis

Work Experience

Die Hardener

- Conduct hardness testing and metallurgical evaluations to ensure the quality and performance of treated dies

- Analyze production data, identify areas for improvement, and implement process modifications to enhance efficiency

- Troubleshoot and resolve production issues, ensuring minimal downtime and maintaining quality standards

- Provide technical support and training to new and existing employees

Die Hardener

- Harden steel dies to produce precision components, meeting dimensional tolerances within ±0.0002 inches

- Utilize vacuum heat treating techniques to achieve optimal hardness and durability of die surfaces

- Operate CNC die sinking machines to create complex geometries and intricate features on dies

- Develop and implement heat treatment plans to optimize material properties and minimize distortion

Accomplishments

- Developed and implemented a new process that reduced die hardening time by 25% while maintaining product quality.

- Identified and resolved a critical issue in the die hardening process, preventing costly product defects and downtime.

- Trained and mentored junior die hardeners, fostering their technical skills and knowledge.

- Collaborated with engineering and production teams to optimize die hardening parameters for improved product performance.

- Established a comprehensive quality control system to ensure consistent die hardening results and meet customer specifications.

Awards

- Received National Die Hardening Excellence Award for outstanding contributions to the industry.

- Recognized with a companywide Innovation Award for developing a novel die hardening technique.

- Honored with a Safety Award for implementing best practices and maintaining a high level of safety in the die hardening shop.

- Recipient of a National Award for Excellence in Die Hardening Technology.

Certificates

- NADCA Certified Die Hardener

- ASQ Certified Quality Auditor

- OSHA 10-Hour General Industry Safety Training

- ISO 9001:2015 Internal Auditor

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Die Hardener

- Highlight quantifiable results and accomplishments in your work experience.

- Demonstrate your knowledge of die casting processes and metallurgy.

- Emphasize your problem-solving and analytical skills.

- Showcase your ability to work independently and as part of a team.

Essential Experience Highlights for a Strong Die Hardener Resume

- Conduct metallurgical analysis of casting materials to determine composition and properties.

- Design and develop dies and molds for casting operations.

- Troubleshoot and resolve casting defects and optimize die life.

- Maintain and repair casting tools and equipment.

- Provide technical assistance to production staff and engineers.

- Stay updated on industry best practices and advancements in die casting technology.

- Work effectively in a team environment and meet production deadlines.

Frequently Asked Questions (FAQ’s) For Die Hardener

What are the key responsibilities of a Die Hardener?

Key responsibilities include conducting metallurgical analysis, designing and developing dies and molds, troubleshooting casting defects, maintaining casting tools and equipment, and providing technical assistance.

What qualifications are required to be a Die Hardener?

A Bachelor’s degree in Metallurgy or a related field, along with experience in die casting, metallurgical analysis, heat treating, tool maintenance, mold design, and casting defects analysis.

What are the career prospects for Die Hardeners?

Die Hardeners with experience and expertise can advance to roles such as Quality Control Manager, Production Supervisor, or Die Casting Engineer.

What are the major industries that employ Die Hardeners?

Die Hardeners are employed in industries such as automotive, aerospace, and construction.

What are some key skills for Die Hardeners?

Die Hardeners should possess strong analytical, problem-solving, and communication skills.