Are you a seasoned Die Maker seeking a new career path? Discover our professionally built Die Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

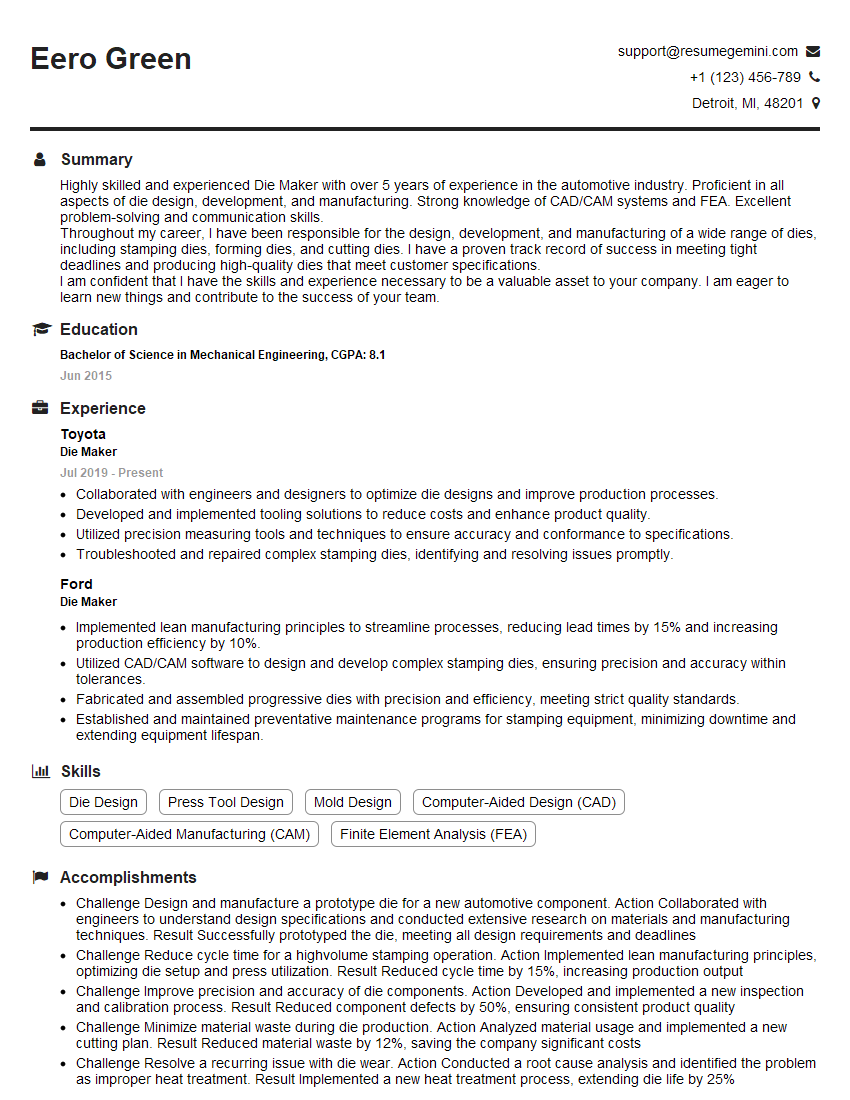

Eero Green

Die Maker

Summary

Highly skilled and experienced Die Maker with over 5 years of experience in the automotive industry. Proficient in all aspects of die design, development, and manufacturing. Strong knowledge of CAD/CAM systems and FEA. Excellent problem-solving and communication skills.

Throughout my career, I have been responsible for the design, development, and manufacturing of a wide range of dies, including stamping dies, forming dies, and cutting dies. I have a proven track record of success in meeting tight deadlines and producing high-quality dies that meet customer specifications.

I am confident that I have the skills and experience necessary to be a valuable asset to your company. I am eager to learn new things and contribute to the success of your team.

Education

Bachelor of Science in Mechanical Engineering

June 2015

Skills

- Die Design

- Press Tool Design

- Mold Design

- Computer-Aided Design (CAD)

- Computer-Aided Manufacturing (CAM)

- Finite Element Analysis (FEA)

Work Experience

Die Maker

- Collaborated with engineers and designers to optimize die designs and improve production processes.

- Developed and implemented tooling solutions to reduce costs and enhance product quality.

- Utilized precision measuring tools and techniques to ensure accuracy and conformance to specifications.

- Troubleshooted and repaired complex stamping dies, identifying and resolving issues promptly.

Die Maker

- Implemented lean manufacturing principles to streamline processes, reducing lead times by 15% and increasing production efficiency by 10%.

- Utilized CAD/CAM software to design and develop complex stamping dies, ensuring precision and accuracy within tolerances.

- Fabricated and assembled progressive dies with precision and efficiency, meeting strict quality standards.

- Established and maintained preventative maintenance programs for stamping equipment, minimizing downtime and extending equipment lifespan.

Accomplishments

- Challenge Design and manufacture a prototype die for a new automotive component. Action Collaborated with engineers to understand design specifications and conducted extensive research on materials and manufacturing techniques. Result Successfully prototyped the die, meeting all design requirements and deadlines

- Challenge Reduce cycle time for a highvolume stamping operation. Action Implemented lean manufacturing principles, optimizing die setup and press utilization. Result Reduced cycle time by 15%, increasing production output

- Challenge Improve precision and accuracy of die components. Action Developed and implemented a new inspection and calibration process. Result Reduced component defects by 50%, ensuring consistent product quality

- Challenge Minimize material waste during die production. Action Analyzed material usage and implemented a new cutting plan. Result Reduced material waste by 12%, saving the company significant costs

- Challenge Resolve a recurring issue with die wear. Action Conducted a root cause analysis and identified the problem as improper heat treatment. Result Implemented a new heat treatment process, extending die life by 25%

Awards

- Received the Production Excellence Award for consistently exceeding production targets

- Recognized with the Die of the Year Award for designing and manufacturing a highly complex die

- Awarded a Certificate of Achievement for implementing a new process that improved productivity by 20%

- Presented with the Employee of the Month award for outstanding contributions to the team

Certificates

- Certified Tool and Die Maker

- Certified Mold Maker

- Certified Press Brake Operator

- Certified Wire EDM Operator

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Die Maker

Highlight your skills and experience.

Make sure your resume showcases your skills in die design, development, and manufacturing. Be sure to mention any specific software or techniques that you are proficient in.Quantify your accomplishments.

When possible, use numbers to quantify your accomplishments. For example, instead of saying “I designed dies for a variety of applications,” you could say “I designed dies that resulted in a 15% increase in production efficiency.”Tailor your resume to the job you are applying for.

Take the time to read the job description and highlight the skills and experience that are most relevant to the position.Proofread your resume carefully.

Make sure your resume is free of errors before you submit it. A well-proofread resume will make a good impression on potential employers.

Essential Experience Highlights for a Strong Die Maker Resume

- Design and develop dies for a variety of applications, including stamping, forming, and cutting.

- Use CAD/CAM systems to create 3D models of dies and simulate their performance.

- Conduct FEA to analyze the stresses and strains on dies and identify potential failure points.

- Manufacture dies using a variety of techniques, including CNC machining, EDM, and wire EDM.

- Inspect dies to ensure that they meet customer specifications and industry standards.

- Maintain and repair dies as needed.

- Work with other members of the engineering team to develop and implement new die designs.

Frequently Asked Questions (FAQ’s) For Die Maker

What is a Die Maker?

A Die Maker is a skilled tradesperson who designs, develops, and manufactures dies. Dies are tools used to shape metal into specific forms. Die Makers use a variety of techniques to create dies, including CNC machining, EDM, and wire EDM.

What are the qualifications to become a Die Maker?

Most Die Makers have a high school diploma or equivalent. Some Die Makers also have a college degree in a related field, such as mechanical engineering or manufacturing engineering. Die Makers typically complete an apprenticeship program or on-the-job training to learn the trade.

What are the job duties of a Die Maker?

Die Makers typically perform the following job duties:

- Design and develop dies for a variety of applications

- Use CAD/CAM systems to create 3D models of dies and simulate their performance

- Conduct FEA to analyze the stresses and strains on dies and identify potential failure points

- Manufacture dies using a variety of techniques, including CNC machining, EDM, and wire EDM

- Inspect dies to ensure that they meet customer specifications and industry standards

- Maintain and repair dies as needed

- Work with other members of the engineering team to develop and implement new die designs

What is the work environment of a Die Maker?

Die Makers typically work in a manufacturing environment. They may be exposed to noise, dust, and fumes. Die Makers may also work with heavy machinery and sharp tools. It is important for Die Makers to wear appropriate safety gear and follow all safety procedures.

What is the salary of a Die Maker?

The salary of a Die Maker can vary depending on their experience, skills, and location. According to the U.S. Bureau of Labor Statistics, the median annual salary for Die Makers was $56,320 in May 2021. The top 10% of earners made more than $92,570, while the bottom 10% earned less than $36,930.

What is the job outlook for Die Makers?

The job outlook for Die Makers is expected to be good over the next few years. The U.S. Bureau of Labor Statistics projects that employment of Die Makers will grow by 9% from 2021 to 2031, faster than the average for all occupations.