Are you a seasoned Die Mechanic seeking a new career path? Discover our professionally built Die Mechanic Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

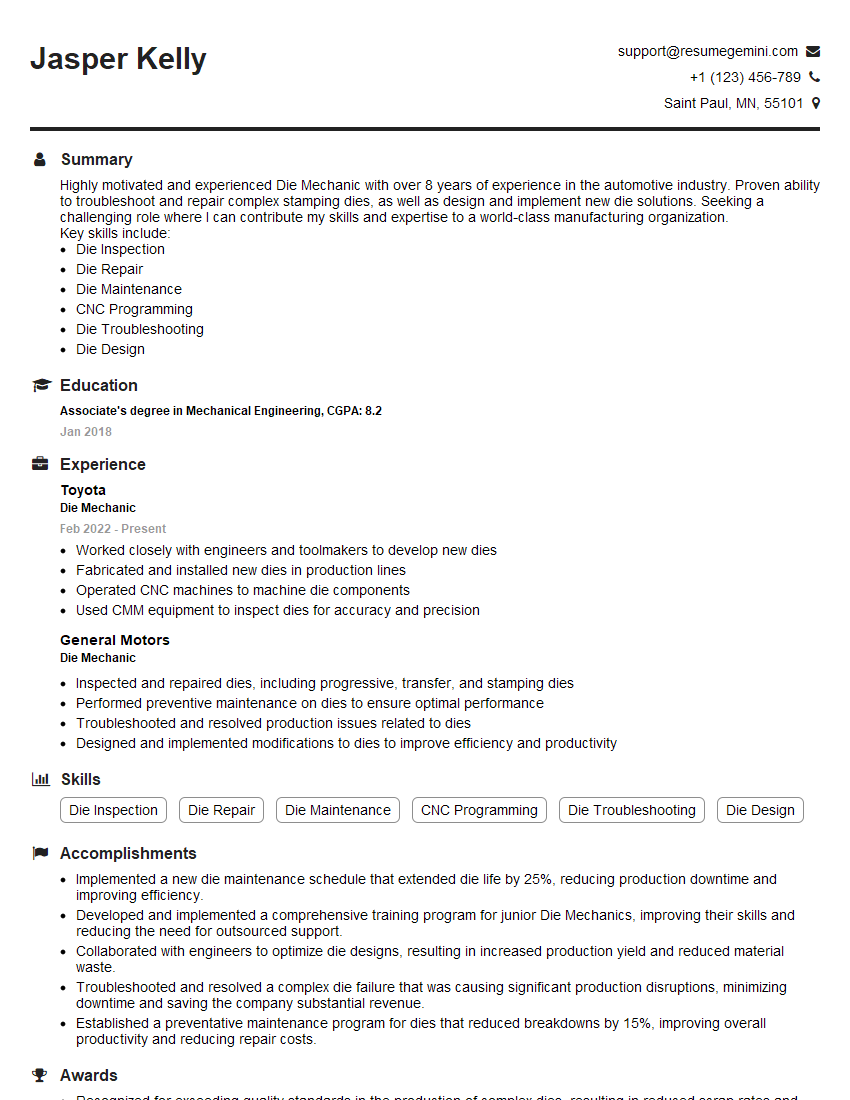

Jasper Kelly

Die Mechanic

Summary

Highly motivated and experienced Die Mechanic with over 8 years of experience in the automotive industry. Proven ability to troubleshoot and repair complex stamping dies, as well as design and implement new die solutions. Seeking a challenging role where I can contribute my skills and expertise to a world-class manufacturing organization.

Key skills include:

- Die Inspection

- Die Repair

- Die Maintenance

- CNC Programming

- Die Troubleshooting

- Die Design

Education

Associate’s degree in Mechanical Engineering

January 2018

Skills

- Die Inspection

- Die Repair

- Die Maintenance

- CNC Programming

- Die Troubleshooting

- Die Design

Work Experience

Die Mechanic

- Worked closely with engineers and toolmakers to develop new dies

- Fabricated and installed new dies in production lines

- Operated CNC machines to machine die components

- Used CMM equipment to inspect dies for accuracy and precision

Die Mechanic

- Inspected and repaired dies, including progressive, transfer, and stamping dies

- Performed preventive maintenance on dies to ensure optimal performance

- Troubleshooted and resolved production issues related to dies

- Designed and implemented modifications to dies to improve efficiency and productivity

Accomplishments

- Implemented a new die maintenance schedule that extended die life by 25%, reducing production downtime and improving efficiency.

- Developed and implemented a comprehensive training program for junior Die Mechanics, improving their skills and reducing the need for outsourced support.

- Collaborated with engineers to optimize die designs, resulting in increased production yield and reduced material waste.

- Troubleshooted and resolved a complex die failure that was causing significant production disruptions, minimizing downtime and saving the company substantial revenue.

- Established a preventative maintenance program for dies that reduced breakdowns by 15%, improving overall productivity and reducing repair costs.

Awards

- Recognized for exceeding quality standards in the production of complex dies, resulting in reduced scrap rates and increased customer satisfaction.

- Awarded Employee of the Month for consistently surpassing performance targets in die maintenance and repair.

- Received a certificate of excellence for exceptional troubleshooting and problemsolving abilities in resolving critical die failures.

Certificates

- Certified Die Mechanic

- Die Repair and Maintenance Certification

- CNC Programming Certification

- Die Design Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Die Mechanic

- Quantify your accomplishments with specific metrics and data points whenever possible.

- Highlight your experience with specific types of dies and materials.

- Showcase your knowledge of industry-standard software and tools.

- Emphasize your commitment to safety and quality.

Essential Experience Highlights for a Strong Die Mechanic Resume

- Inspected and maintained stamping dies to ensure optimal performance and prevent breakdowns

- Repaired and rebuilt damaged dies, including replacing worn components and adjusting clearances

- Troubleshooted and resolved die-related issues, minimizing downtime and scrap rates

- Programmed and operated CNC machines to modify and repair dies

- Designed and developed new die solutions to improve efficiency and reduce costs

- Supervised and mentored junior Die Mechanics, providing guidance and training

Frequently Asked Questions (FAQ’s) For Die Mechanic

What are the primary responsibilities of a Die Mechanic?

Die Mechanics are responsible for the maintenance, repair, and troubleshooting of stamping dies used in the manufacturing process. They ensure that dies are operating efficiently and producing high-quality parts.

What are the educational requirements to become a Die Mechanic?

Most Die Mechanics have an associate’s degree in Mechanical Engineering or a related field. Some may also have completed an apprenticeship program.

What skills are required to be a successful Die Mechanic?

Die Mechanics need to have a strong understanding of mechanical principles, as well as experience with CNC programming, die design, and troubleshooting.

What are the career prospects for Die Mechanics?

Die Mechanics are in high demand in the manufacturing industry, especially in automotive and aerospace. They can advance to management positions or specialize in specific areas such as die design or troubleshooting.

What is the salary range for Die Mechanics?

The salary range for Die Mechanics varies depending on experience and location. According to the U.S. Bureau of Labor Statistics, the median annual salary for Die Mechanics was $49,520 in May 2021.

What is the work environment like for Die Mechanics?

Die Mechanics typically work in manufacturing facilities, where they may be exposed to noise, dust, and chemicals. They may also need to work overtime or on weekends to meet production demands.