Are you a seasoned Die Presser seeking a new career path? Discover our professionally built Die Presser Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

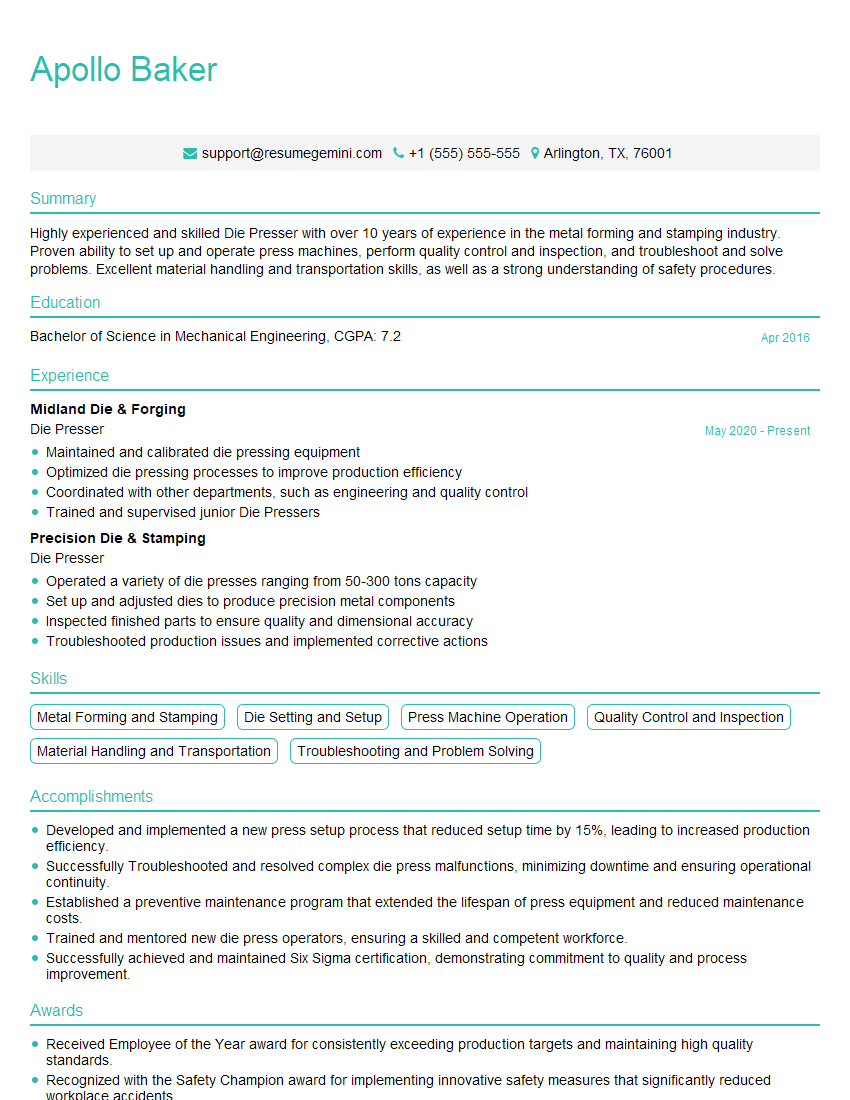

Apollo Baker

Die Presser

Summary

Highly experienced and skilled Die Presser with over 10 years of experience in the metal forming and stamping industry. Proven ability to set up and operate press machines, perform quality control and inspection, and troubleshoot and solve problems. Excellent material handling and transportation skills, as well as a strong understanding of safety procedures.

Education

Bachelor of Science in Mechanical Engineering

April 2016

Skills

- Metal Forming and Stamping

- Die Setting and Setup

- Press Machine Operation

- Quality Control and Inspection

- Material Handling and Transportation

- Troubleshooting and Problem Solving

Work Experience

Die Presser

- Maintained and calibrated die pressing equipment

- Optimized die pressing processes to improve production efficiency

- Coordinated with other departments, such as engineering and quality control

- Trained and supervised junior Die Pressers

Die Presser

- Operated a variety of die presses ranging from 50-300 tons capacity

- Set up and adjusted dies to produce precision metal components

- Inspected finished parts to ensure quality and dimensional accuracy

- Troubleshooted production issues and implemented corrective actions

Accomplishments

- Developed and implemented a new press setup process that reduced setup time by 15%, leading to increased production efficiency.

- Successfully Troubleshooted and resolved complex die press malfunctions, minimizing downtime and ensuring operational continuity.

- Established a preventive maintenance program that extended the lifespan of press equipment and reduced maintenance costs.

- Trained and mentored new die press operators, ensuring a skilled and competent workforce.

- Successfully achieved and maintained Six Sigma certification, demonstrating commitment to quality and process improvement.

Awards

- Received Employee of the Year award for consistently exceeding production targets and maintaining high quality standards.

- Recognized with the Safety Champion award for implementing innovative safety measures that significantly reduced workplace accidents.

- Awarded the Quality Control Excellence award for maintaining high product quality and detecting and resolving defects.

- Received recognition for outstanding teamwork and collaboration in optimizing production processes.

Certificates

- Certified Production Technician (CPT)

- National Institute for Metalworking Skills (NIMS) Certification

- Society of Manufacturing Engineers (SME) Certification

- American Welding Society (AWS) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Die Presser

- Highlight your experience in operating and setting up die presses.

- Demonstrate your knowledge of quality control and inspection procedures.

- Showcase your problem-solving and troubleshooting skills.

- Emphasize your attention to detail and commitment to safety.

Essential Experience Highlights for a Strong Die Presser Resume

- Set up and operate die presses to form metal parts according to specifications.

- Inspect and measure finished parts to ensure they meet quality standards.

- Troubleshoot and solve problems with press machines and dies.

- Handle and transport materials and parts safely and efficiently.

- Maintain a clean and organized work area.

- Adhere to all safety procedures and regulations.

- Work as part of a team to achieve production goals.

Frequently Asked Questions (FAQ’s) For Die Presser

What is a Die Presser?

A Die Presser is a skilled technician who operates and sets up die presses to form metal parts according to specifications.

What skills are required to be a Die Presser?

Die Pressers typically need a high school diploma or equivalent and experience in operating and setting up die presses. They also need to have a strong understanding of quality control and inspection procedures, as well as problem-solving and troubleshooting skills.

What is the work environment of a Die Presser like?

Die Pressers typically work in manufacturing environments, operating and setting up die presses to form metal parts. They may work in teams or independently, and may be required to work overtime to meet production deadlines.

What is the career outlook for Die Pressers?

The career outlook for Die Pressers is expected to be good, as there is a growing demand for skilled technicians in the manufacturing industry.

What are the earning prospects for Die Pressers?

Die Pressers can earn a good salary, depending on their experience and skills. The median annual salary for Die Pressers is around $45,000.

What are the benefits of being a Die Presser?

Die Pressers can enjoy a number of benefits, including a good salary, job security, and the opportunity to work with a variety of materials and equipment.

What are the challenges of being a Die Presser?

Die Pressers can face a number of challenges, including working in a noisy and potentially hazardous environment, and being required to work overtime to meet production deadlines.

What are the tips for writing a standout Die Presser resume?

To write a standout Die Presser resume, you should highlight your experience in operating and setting up die presses, demonstrate your knowledge of quality control and inspection procedures, showcase your problem-solving and troubleshooting skills, and emphasize your attention to detail and commitment to safety.