Are you a seasoned Die Sinker Apprentice seeking a new career path? Discover our professionally built Die Sinker Apprentice Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

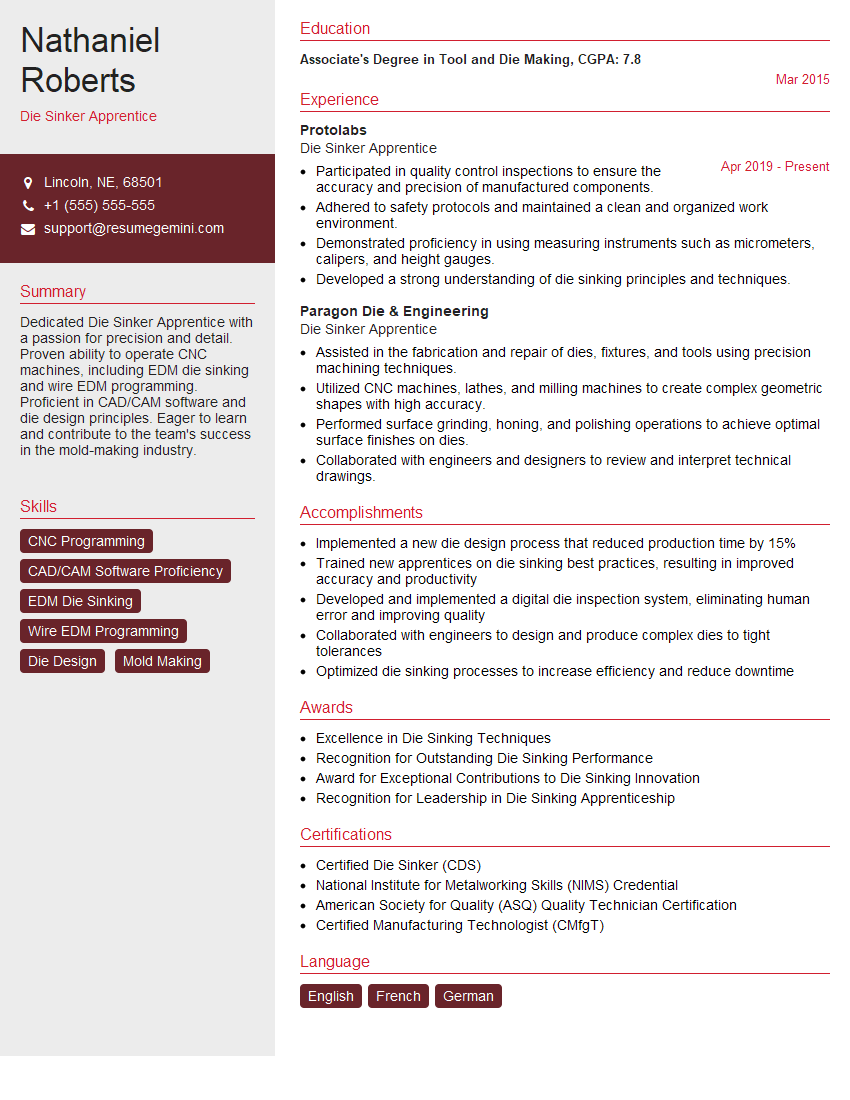

Nathaniel Roberts

Die Sinker Apprentice

Summary

Dedicated Die Sinker Apprentice with a passion for precision and detail. Proven ability to operate CNC machines, including EDM die sinking and wire EDM programming. Proficient in CAD/CAM software and die design principles. Eager to learn and contribute to the team’s success in the mold-making industry.

Education

Associate’s Degree in Tool and Die Making

March 2015

Skills

- CNC Programming

- CAD/CAM Software Proficiency

- EDM Die Sinking

- Wire EDM Programming

- Die Design

- Mold Making

Work Experience

Die Sinker Apprentice

- Participated in quality control inspections to ensure the accuracy and precision of manufactured components.

- Adhered to safety protocols and maintained a clean and organized work environment.

- Demonstrated proficiency in using measuring instruments such as micrometers, calipers, and height gauges.

- Developed a strong understanding of die sinking principles and techniques.

Die Sinker Apprentice

- Assisted in the fabrication and repair of dies, fixtures, and tools using precision machining techniques.

- Utilized CNC machines, lathes, and milling machines to create complex geometric shapes with high accuracy.

- Performed surface grinding, honing, and polishing operations to achieve optimal surface finishes on dies.

- Collaborated with engineers and designers to review and interpret technical drawings.

Accomplishments

- Implemented a new die design process that reduced production time by 15%

- Trained new apprentices on die sinking best practices, resulting in improved accuracy and productivity

- Developed and implemented a digital die inspection system, eliminating human error and improving quality

- Collaborated with engineers to design and produce complex dies to tight tolerances

- Optimized die sinking processes to increase efficiency and reduce downtime

Awards

- Excellence in Die Sinking Techniques

- Recognition for Outstanding Die Sinking Performance

- Award for Exceptional Contributions to Die Sinking Innovation

- Recognition for Leadership in Die Sinking Apprenticeship

Certificates

- Certified Die Sinker (CDS)

- National Institute for Metalworking Skills (NIMS) Credential

- American Society for Quality (ASQ) Quality Technician Certification

- Certified Manufacturing Technologist (CMfgT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Die Sinker Apprentice

- Highlight your technical skills, such as CNC programming, CAD/CAM software proficiency, and EDM die sinking experience.

- Showcase your understanding of die design principles and mold-making processes.

- Emphasize your eagerness to learn and grow within the industry.

- Include specific examples and quantifiable results that demonstrate your abilities.

Essential Experience Highlights for a Strong Die Sinker Apprentice Resume

- Operate CNC machines (EDM die sinking, wire EDM) to create complex molds and dies with precision and accuracy.

- Utilize CAD/CAM software to design and program molds and dies, ensuring optimal performance.

- Inspect and measure completed molds and dies to ensure compliance with specifications.

- Troubleshoot and resolve technical issues related to CNC machines and EDM processes.

- Maintain a clean and organized work area, adhering to safety protocols.

- Collaborate with experienced die makers to learn best practices and enhance skills.

Frequently Asked Questions (FAQ’s) For Die Sinker Apprentice

What are the typical job duties of a Die Sinker Apprentice?

Die Sinker Apprentices typically operate CNC machines (EDM die sinking, wire EDM) to create molds and dies, utilize CAD/CAM software for design and programming, inspect completed molds and dies, troubleshoot technical issues, maintain a clean work area, and collaborate with experienced die makers.

What are the educational requirements for a Die Sinker Apprentice?

An Associate’s Degree in Tool and Die Making or a related field is typically required to become a Die Sinker Apprentice.

What skills are essential for a Die Sinker Apprentice?

Essential skills for a Die Sinker Apprentice include CNC programming, CAD/CAM software proficiency, EDM die sinking, wire EDM programming, die design principles, and mold-making knowledge.

What are the career advancement opportunities for a Die Sinker Apprentice?

With experience and additional training, Die Sinker Apprentices can advance to positions such as Die Sinker, Mold Maker, or CNC Programmer.

What is the typical salary range for a Die Sinker Apprentice?

The salary range for Die Sinker Apprentices can vary depending on experience, location, and company size, but typically falls within the range of $20,000 to $40,000 per year.

What are the job outlook prospects for a Die Sinker Apprentice?

The job outlook for Die Sinker Apprentices is expected to be positive, with a projected growth rate of 10% over the next decade due to the increasing demand for skilled workers in the manufacturing industry.

What are the key qualities of a successful Die Sinker Apprentice?

Successful Die Sinker Apprentices possess strong technical skills, attention to detail, problem-solving abilities, and a willingness to learn and grow in the field.

What are the common work environments for a Die Sinker Apprentice?

Die Sinker Apprentices typically work in manufacturing facilities, tool and die shops, or mold-making companies.