Are you a seasoned Diecast Machine Operator seeking a new career path? Discover our professionally built Diecast Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

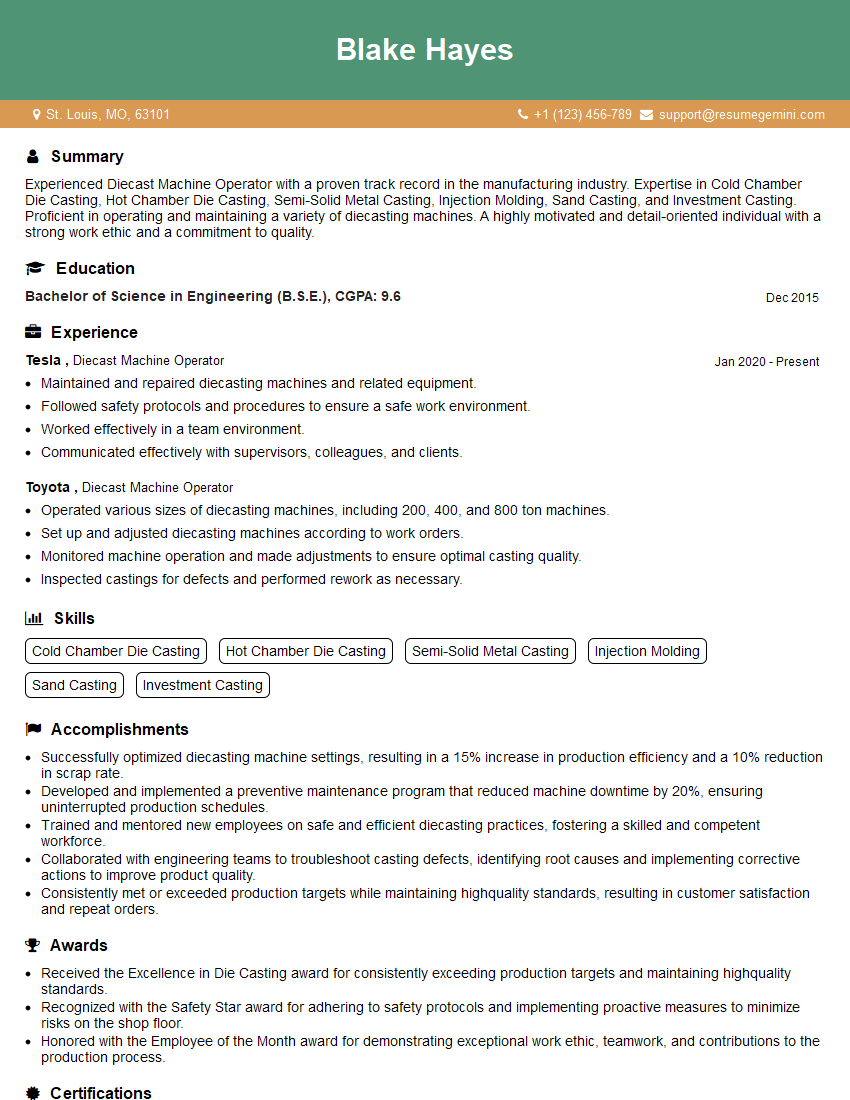

Blake Hayes

Diecast Machine Operator

Summary

Experienced Diecast Machine Operator with a proven track record in the manufacturing industry. Expertise in Cold Chamber Die Casting, Hot Chamber Die Casting, Semi-Solid Metal Casting, Injection Molding, Sand Casting, and Investment Casting. Proficient in operating and maintaining a variety of diecasting machines. A highly motivated and detail-oriented individual with a strong work ethic and a commitment to quality.

Education

Bachelor of Science in Engineering (B.S.E.)

December 2015

Skills

- Cold Chamber Die Casting

- Hot Chamber Die Casting

- Semi-Solid Metal Casting

- Injection Molding

- Sand Casting

- Investment Casting

Work Experience

Diecast Machine Operator

- Maintained and repaired diecasting machines and related equipment.

- Followed safety protocols and procedures to ensure a safe work environment.

- Worked effectively in a team environment.

- Communicated effectively with supervisors, colleagues, and clients.

Diecast Machine Operator

- Operated various sizes of diecasting machines, including 200, 400, and 800 ton machines.

- Set up and adjusted diecasting machines according to work orders.

- Monitored machine operation and made adjustments to ensure optimal casting quality.

- Inspected castings for defects and performed rework as necessary.

Accomplishments

- Successfully optimized diecasting machine settings, resulting in a 15% increase in production efficiency and a 10% reduction in scrap rate.

- Developed and implemented a preventive maintenance program that reduced machine downtime by 20%, ensuring uninterrupted production schedules.

- Trained and mentored new employees on safe and efficient diecasting practices, fostering a skilled and competent workforce.

- Collaborated with engineering teams to troubleshoot casting defects, identifying root causes and implementing corrective actions to improve product quality.

- Consistently met or exceeded production targets while maintaining highquality standards, resulting in customer satisfaction and repeat orders.

Awards

- Received the Excellence in Die Casting award for consistently exceeding production targets and maintaining highquality standards.

- Recognized with the Safety Star award for adhering to safety protocols and implementing proactive measures to minimize risks on the shop floor.

- Honored with the Employee of the Month award for demonstrating exceptional work ethic, teamwork, and contributions to the production process.

Certificates

- Certified Die Casting Technician (CDCT)

- Certified Die Casting Engineer (CDCE)

- Certified Manufacturing Engineer (CMfgE)

- Certified Quality Engineer (CQE)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Diecast Machine Operator

- Highlight your experience and skills in the diecasting industry, including specific casting techniques.

- Quantify your accomplishments and provide specific examples of your contributions to previous roles.

- Include keywords relevant to the diecasting industry in your resume, such as ‘Cold Chamber Die Casting’ and ‘Hot Chamber Die Casting’.

- Tailor your resume to each job application, highlighting the skills and experience that are most relevant to the specific position.

Essential Experience Highlights for a Strong Diecast Machine Operator Resume

- Operate and maintain diecasting machines, ensuring optimal performance and production efficiency.

- Set up and adjust diecasting machines according to production specifications and quality standards.

- Monitor and control casting processes, ensuring the production of high-quality castings.

- Inspect and measure castings to ensure dimensional accuracy and adherence to specifications.

- Perform preventative maintenance on diecasting machines and equipment, ensuring minimal downtime.

- Troubleshoot and resolve machine malfunctions, maintaining efficient production operations.

Frequently Asked Questions (FAQ’s) For Diecast Machine Operator

What is the role of a Diecast Machine Operator?

A Diecast Machine Operator is responsible for operating and maintaining diecasting machines, ensuring the production of high-quality castings. They set up and adjust machines, monitor casting processes, inspect castings, and perform preventative maintenance.

What are the different types of diecasting?

There are several types of diecasting, including Cold Chamber Die Casting, Hot Chamber Die Casting, Semi-Solid Metal Casting, Injection Molding, Sand Casting, and Investment Casting.

What skills are required to be a Diecast Machine Operator?

Diecast Machine Operators require skills in operating and maintaining diecasting machines, as well as knowledge of casting techniques and quality standards. They should also have good mechanical aptitude and problem-solving skills.

What is the work environment of a Diecast Machine Operator like?

Diecast Machine Operators typically work in manufacturing environments, operating machinery and performing quality control checks. They may work in teams or individually, and must be able to work in a fast-paced environment.

What are the career prospects for a Diecast Machine Operator?

Diecast Machine Operators can advance their careers by gaining experience and developing specialized skills. They may become Supervisors or Managers, or move into related areas such as Quality Control or Engineering.