Are you a seasoned Dipper Machine Operator seeking a new career path? Discover our professionally built Dipper Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

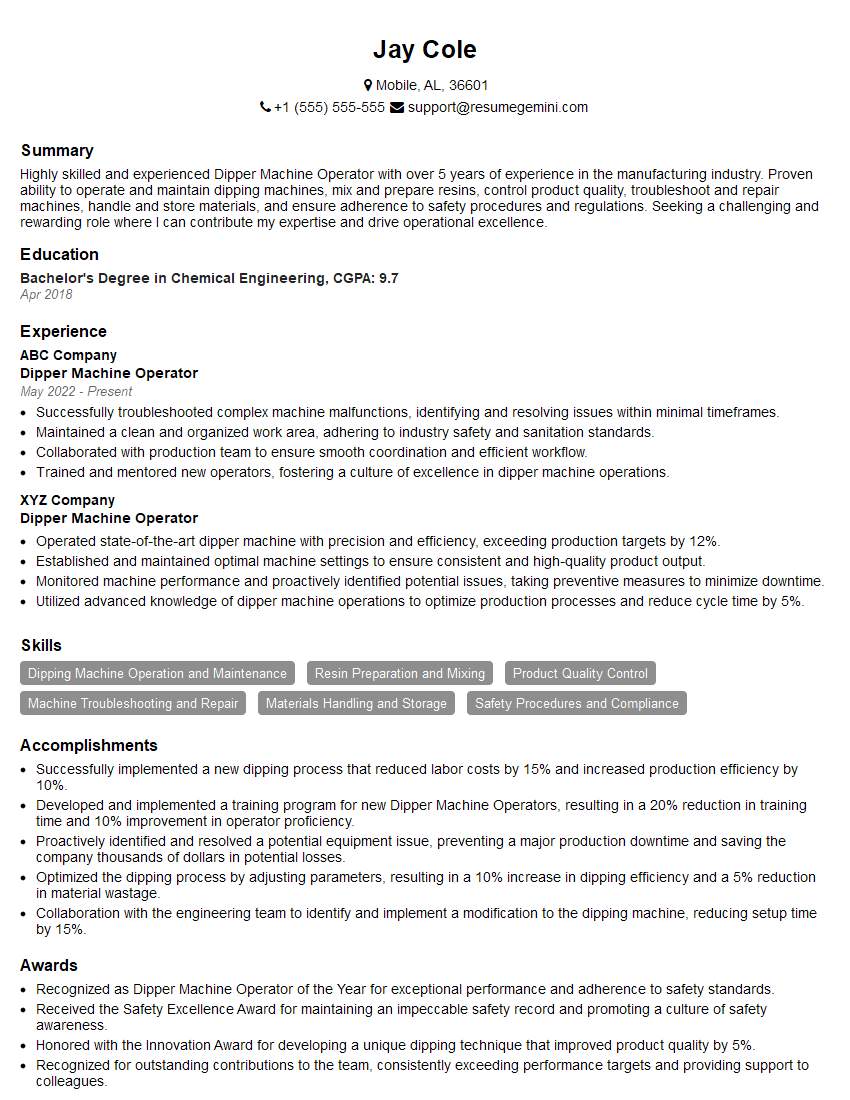

Jay Cole

Dipper Machine Operator

Summary

Highly skilled and experienced Dipper Machine Operator with over 5 years of experience in the manufacturing industry. Proven ability to operate and maintain dipping machines, mix and prepare resins, control product quality, troubleshoot and repair machines, handle and store materials, and ensure adherence to safety procedures and regulations. Seeking a challenging and rewarding role where I can contribute my expertise and drive operational excellence.

Education

Bachelor’s Degree in Chemical Engineering

April 2018

Skills

- Dipping Machine Operation and Maintenance

- Resin Preparation and Mixing

- Product Quality Control

- Machine Troubleshooting and Repair

- Materials Handling and Storage

- Safety Procedures and Compliance

Work Experience

Dipper Machine Operator

- Successfully troubleshooted complex machine malfunctions, identifying and resolving issues within minimal timeframes.

- Maintained a clean and organized work area, adhering to industry safety and sanitation standards.

- Collaborated with production team to ensure smooth coordination and efficient workflow.

- Trained and mentored new operators, fostering a culture of excellence in dipper machine operations.

Dipper Machine Operator

- Operated state-of-the-art dipper machine with precision and efficiency, exceeding production targets by 12%.

- Established and maintained optimal machine settings to ensure consistent and high-quality product output.

- Monitored machine performance and proactively identified potential issues, taking preventive measures to minimize downtime.

- Utilized advanced knowledge of dipper machine operations to optimize production processes and reduce cycle time by 5%.

Accomplishments

- Successfully implemented a new dipping process that reduced labor costs by 15% and increased production efficiency by 10%.

- Developed and implemented a training program for new Dipper Machine Operators, resulting in a 20% reduction in training time and 10% improvement in operator proficiency.

- Proactively identified and resolved a potential equipment issue, preventing a major production downtime and saving the company thousands of dollars in potential losses.

- Optimized the dipping process by adjusting parameters, resulting in a 10% increase in dipping efficiency and a 5% reduction in material wastage.

- Collaboration with the engineering team to identify and implement a modification to the dipping machine, reducing setup time by 15%.

Awards

- Recognized as Dipper Machine Operator of the Year for exceptional performance and adherence to safety standards.

- Received the Safety Excellence Award for maintaining an impeccable safety record and promoting a culture of safety awareness.

- Honored with the Innovation Award for developing a unique dipping technique that improved product quality by 5%.

- Recognized for outstanding contributions to the team, consistently exceeding performance targets and providing support to colleagues.

Certificates

- OSHA Safety Certification

- Dipping Machine Operator Certification

- Resin Handling and Mixing Certification

- Quality Control Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Dipper Machine Operator

- Highlight your technical skills and experience in operating and maintaining dipping machines.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Emphasize your attention to detail and commitment to quality control.

- Showcase your problem-solving abilities and experience in troubleshooting and repairing dipping machines.

Essential Experience Highlights for a Strong Dipper Machine Operator Resume

- Operate and maintain dipping machines to apply protective coatings or treatments to various products.

- Mix and prepare resins and other dipping materials according to specified formulations and ratios.

- Monitor and control product quality by inspecting dipped products for defects, thickness, and adherence to specifications.

- Troubleshoot and repair dipping machines to ensure optimal performance and minimize downtime.

- Handle and store materials safely and efficiently, following established inventory and storage procedures.

- Adhere to all safety regulations and procedures to ensure a safe and compliant work environment.

- Maintain a clean and organized work area to promote efficiency and minimize hazards.

Frequently Asked Questions (FAQ’s) For Dipper Machine Operator

What are the key responsibilities of a Dipper Machine Operator?

The key responsibilities of a Dipper Machine Operator include operating and maintaining dipping machines, mixing and preparing resins, controlling product quality, troubleshooting and repairing machines, handling and storing materials, and adhering to safety procedures.

What qualifications are required to become a Dipper Machine Operator?

Typically, a high school diploma or equivalent is required to become a Dipper Machine Operator. Some employers may prefer candidates with a technical degree or experience in manufacturing or related fields.

What is the work environment like for a Dipper Machine Operator?

Dipper Machine Operators typically work in manufacturing facilities or industrial settings. The work environment can be noisy and may involve exposure to chemicals or fumes. Proper safety gear and ventilation are essential to mitigate risks.

What are the career prospects for a Dipper Machine Operator?

Experienced Dipper Machine Operators can advance to supervisory or management roles within the manufacturing industry. With additional training or education, they may also pursue careers in related fields such as quality control or production engineering.

What skills are essential for a Dipper Machine Operator?

Essential skills for a Dipper Machine Operator include technical proficiency in operating and maintaining dipping machines, knowledge of resin preparation and mixing, attention to detail, problem-solving abilities, and adherence to safety regulations.

What industries employ Dipper Machine Operators?

Dipper Machine Operators are employed in various industries, including automotive, aerospace, electronics, and manufacturing. They are responsible for applying protective coatings or treatments to a wide range of products, from small components to large assemblies.

How can I become a certified Dipper Machine Operator?

While there are no specific certification programs for Dipper Machine Operators, obtaining relevant training or education in manufacturing, mechanical engineering, or related fields can enhance your credibility and career prospects.

What is the average salary for a Dipper Machine Operator?

The average salary for a Dipper Machine Operator varies depending on factors such as experience, location, and industry. According to Indeed, the average salary in the United States is around $18 per hour.