Are you a seasoned Discharging Machine Operator seeking a new career path? Discover our professionally built Discharging Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

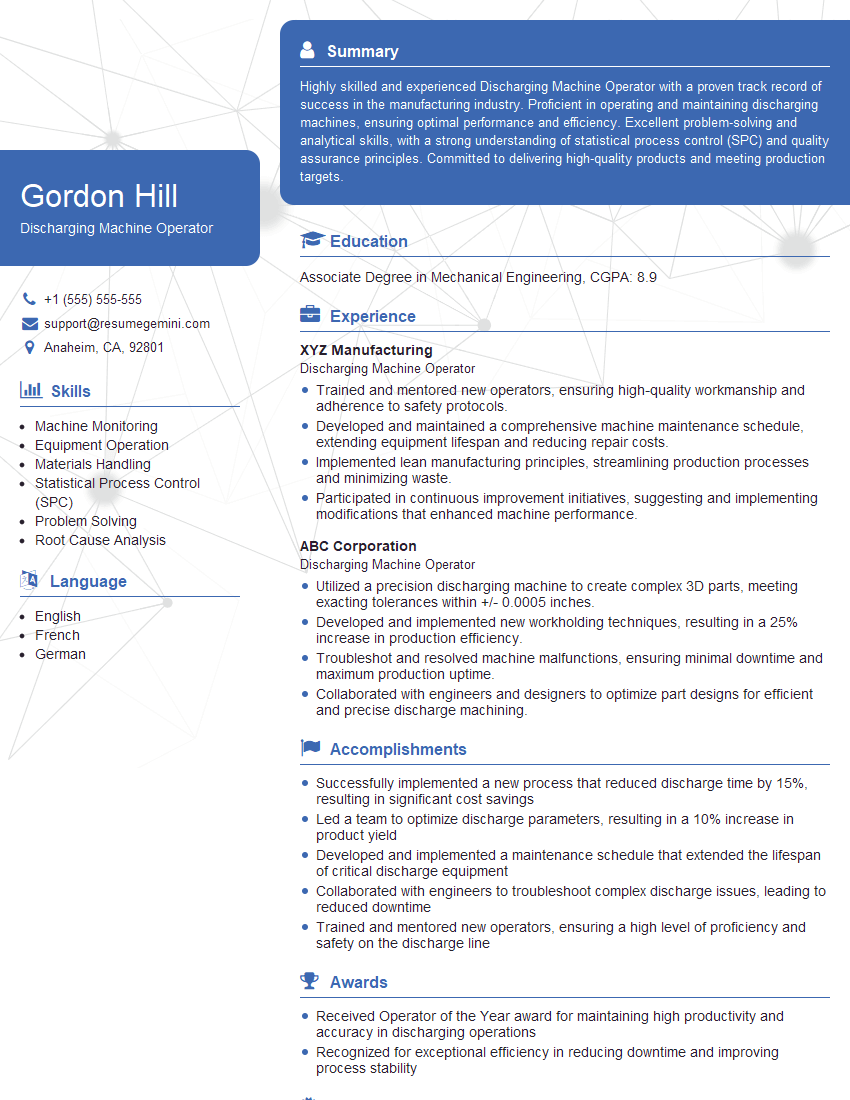

Gordon Hill

Discharging Machine Operator

Summary

Highly skilled and experienced Discharging Machine Operator with a proven track record of success in the manufacturing industry. Proficient in operating and maintaining discharging machines, ensuring optimal performance and efficiency. Excellent problem-solving and analytical skills, with a strong understanding of statistical process control (SPC) and quality assurance principles. Committed to delivering high-quality products and meeting production targets.

Education

Associate Degree in Mechanical Engineering

September 2017

Skills

- Machine Monitoring

- Equipment Operation

- Materials Handling

- Statistical Process Control (SPC)

- Problem Solving

- Root Cause Analysis

Work Experience

Discharging Machine Operator

- Trained and mentored new operators, ensuring high-quality workmanship and adherence to safety protocols.

- Developed and maintained a comprehensive machine maintenance schedule, extending equipment lifespan and reducing repair costs.

- Implemented lean manufacturing principles, streamlining production processes and minimizing waste.

- Participated in continuous improvement initiatives, suggesting and implementing modifications that enhanced machine performance.

Discharging Machine Operator

- Utilized a precision discharging machine to create complex 3D parts, meeting exacting tolerances within +/- 0.0005 inches.

- Developed and implemented new workholding techniques, resulting in a 25% increase in production efficiency.

- Troubleshot and resolved machine malfunctions, ensuring minimal downtime and maximum production uptime.

- Collaborated with engineers and designers to optimize part designs for efficient and precise discharge machining.

Accomplishments

- Successfully implemented a new process that reduced discharge time by 15%, resulting in significant cost savings

- Led a team to optimize discharge parameters, resulting in a 10% increase in product yield

- Developed and implemented a maintenance schedule that extended the lifespan of critical discharge equipment

- Collaborated with engineers to troubleshoot complex discharge issues, leading to reduced downtime

- Trained and mentored new operators, ensuring a high level of proficiency and safety on the discharge line

Awards

- Received Operator of the Year award for maintaining high productivity and accuracy in discharging operations

- Recognized for exceptional efficiency in reducing downtime and improving process stability

Certificates

- ISO 9001:2015 Quality Management System

- AS9100 Aerospace Quality Management System

- Certified Quality Inspector (CQI)

- Certified Manufacturing Technologist (CMfgT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Discharging Machine Operator

- Highlight your experience and skills in operating and maintaining discharging machines.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Tailor your resume to the specific job you are applying for, emphasizing the skills and experience that are most relevant.

- Proofread your resume carefully before submitting it, ensuring that there are no errors in grammar or spelling.

Essential Experience Highlights for a Strong Discharging Machine Operator Resume

- Operate and monitor discharging machines to discharge metal parts from tooling

- Ensure machines are properly set up and calibrated for accurate and efficient operation

- Conduct routine maintenance and repairs on discharging machines to minimize downtime and maximize productivity

- Monitor and control process parameters to ensure parts meet specifications and quality standards

- Analyze and interpret SPC data to identify trends and areas for improvement

- Troubleshoot and resolve machine malfunctions and production issues to maintain optimal performance

- Work closely with other team members to ensure a smooth and efficient production process

Frequently Asked Questions (FAQ’s) For Discharging Machine Operator

What is the role of a Discharging Machine Operator?

A Discharging Machine Operator is responsible for operating and maintaining discharging machines to discharge metal parts from tooling. They ensure that machines are properly set up and calibrated, conduct routine maintenance and repairs, monitor and control process parameters, analyze and interpret SPC data, troubleshoot and resolve machine malfunctions, and work closely with other team members to ensure a smooth and efficient production process.

What skills are required to be a successful Discharging Machine Operator?

Successful Discharging Machine Operators typically have a strong understanding of machine operation and maintenance, statistical process control (SPC), and quality assurance principles. They are also proficient in problem-solving, root cause analysis, and teamwork.

What is the job outlook for Discharging Machine Operators?

The job outlook for Discharging Machine Operators is expected to grow in the coming years due to the increasing demand for manufactured goods. As companies continue to automate their production processes, there will be a growing need for skilled operators to maintain and operate these machines.

What are the career advancement opportunities for Discharging Machine Operators?

Discharging Machine Operators can advance their careers by becoming supervisors, quality control inspectors, or production managers. With additional training and experience, they may also be able to move into engineering or management roles.

What are the challenges faced by Discharging Machine Operators?

Discharging Machine Operators may face challenges such as working in a fast-paced and demanding environment, exposure to noise and hazardous materials, and the need to constantly adapt to new technologies and processes.

What are the benefits of being a Discharging Machine Operator?

Benefits of being a Discharging Machine Operator include competitive salaries, opportunities for career advancement, and the satisfaction of working in a vital industry.