Are you a seasoned Drier seeking a new career path? Discover our professionally built Drier Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

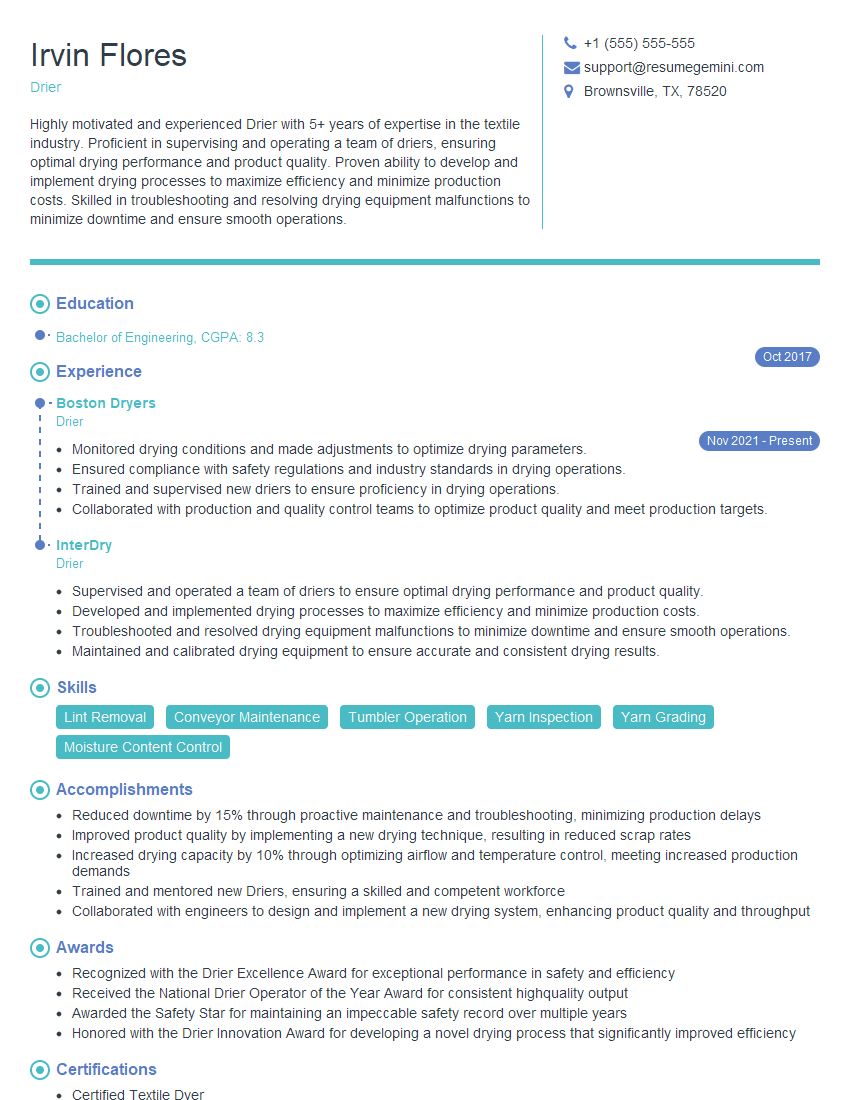

Irvin Flores

Drier

Summary

Highly motivated and experienced Drier with 5+ years of expertise in the textile industry. Proficient in supervising and operating a team of driers, ensuring optimal drying performance and product quality. Proven ability to develop and implement drying processes to maximize efficiency and minimize production costs. Skilled in troubleshooting and resolving drying equipment malfunctions to minimize downtime and ensure smooth operations.

Education

Bachelor of Engineering

October 2017

Skills

- Lint Removal

- Conveyor Maintenance

- Tumbler Operation

- Yarn Inspection

- Yarn Grading

- Moisture Content Control

Work Experience

Drier

- Monitored drying conditions and made adjustments to optimize drying parameters.

- Ensured compliance with safety regulations and industry standards in drying operations.

- Trained and supervised new driers to ensure proficiency in drying operations.

- Collaborated with production and quality control teams to optimize product quality and meet production targets.

Drier

- Supervised and operated a team of driers to ensure optimal drying performance and product quality.

- Developed and implemented drying processes to maximize efficiency and minimize production costs.

- Troubleshooted and resolved drying equipment malfunctions to minimize downtime and ensure smooth operations.

- Maintained and calibrated drying equipment to ensure accurate and consistent drying results.

Accomplishments

- Reduced downtime by 15% through proactive maintenance and troubleshooting, minimizing production delays

- Improved product quality by implementing a new drying technique, resulting in reduced scrap rates

- Increased drying capacity by 10% through optimizing airflow and temperature control, meeting increased production demands

- Trained and mentored new Driers, ensuring a skilled and competent workforce

- Collaborated with engineers to design and implement a new drying system, enhancing product quality and throughput

Awards

- Recognized with the Drier Excellence Award for exceptional performance in safety and efficiency

- Received the National Drier Operator of the Year Award for consistent highquality output

- Awarded the Safety Star for maintaining an impeccable safety record over multiple years

- Honored with the Drier Innovation Award for developing a novel drying process that significantly improved efficiency

Certificates

- Certified Textile Dyer

- Certified Colorist

- Certified Fabric Finisher

- Certified Textile Engineer

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Drier

- Quantify your accomplishments by using numbers and metrics whenever possible.

- Highlight your experience with different types of drying equipment and processes.

- Emphasize your ability to work independently and as part of a team.

- Proofread your resume carefully for any errors in grammar or spelling.

Essential Experience Highlights for a Strong Drier Resume

- Supervised and operated a team of driers to ensure optimal drying performance and product quality.

- Developed and implemented drying processes to maximize efficiency and minimize production costs.

- Troubleshooted and resolved drying equipment malfunctions to minimize downtime and ensure smooth operations.

- Maintained and calibrated drying equipment to ensure accurate and consistent drying results.

- Monitored drying conditions and made adjustments to optimize drying parameters.

- Ensured compliance with safety regulations and industry standards in drying operations.

- Trained and supervised new driers to ensure proficiency in drying operations.

Frequently Asked Questions (FAQ’s) For Drier

What are the key responsibilities of a Drier?

The key responsibilities of a Drier include supervising and operating a team of driers, developing and implementing drying processes, troubleshooting and resolving drying equipment malfunctions, maintaining and calibrating drying equipment, monitoring drying conditions, ensuring compliance with safety regulations, and training and supervising new driers.

What are the educational requirements for a Drier?

Most Driers have a high school diploma or equivalent. Some employers may prefer candidates with a bachelor’s degree in engineering or a related field.

What are the career prospects for a Drier?

Driers can advance to supervisory or management positions within the textile industry. They may also choose to specialize in a particular type of drying equipment or process.

What are the challenges of working as a Drier?

The challenges of working as a Drier include working in a hot and humid environment, exposure to chemicals, and the need to be able to work independently and as part of a team.

What are the benefits of working as a Drier?

The benefits of working as a Drier include a steady income, the opportunity to work with different types of drying equipment and processes, and the chance to advance to supervisory or management positions.

What are the most important skills for a Drier?

The most important skills for a Drier include the ability to operate and maintain drying equipment, troubleshoot and resolve drying equipment malfunctions, and work independently and as part of a team.

What are the different types of drying equipment that a Drier may work with?

The different types of drying equipment that a Drier may work with include rotary dryers, tumbler dryers, and fluidized bed dryers.

What are the different types of drying processes that a Drier may be involved in?

The different types of drying processes that a Drier may be involved in include batch drying, continuous drying, and freeze drying.