Are you a seasoned Drill Presser seeking a new career path? Discover our professionally built Drill Presser Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

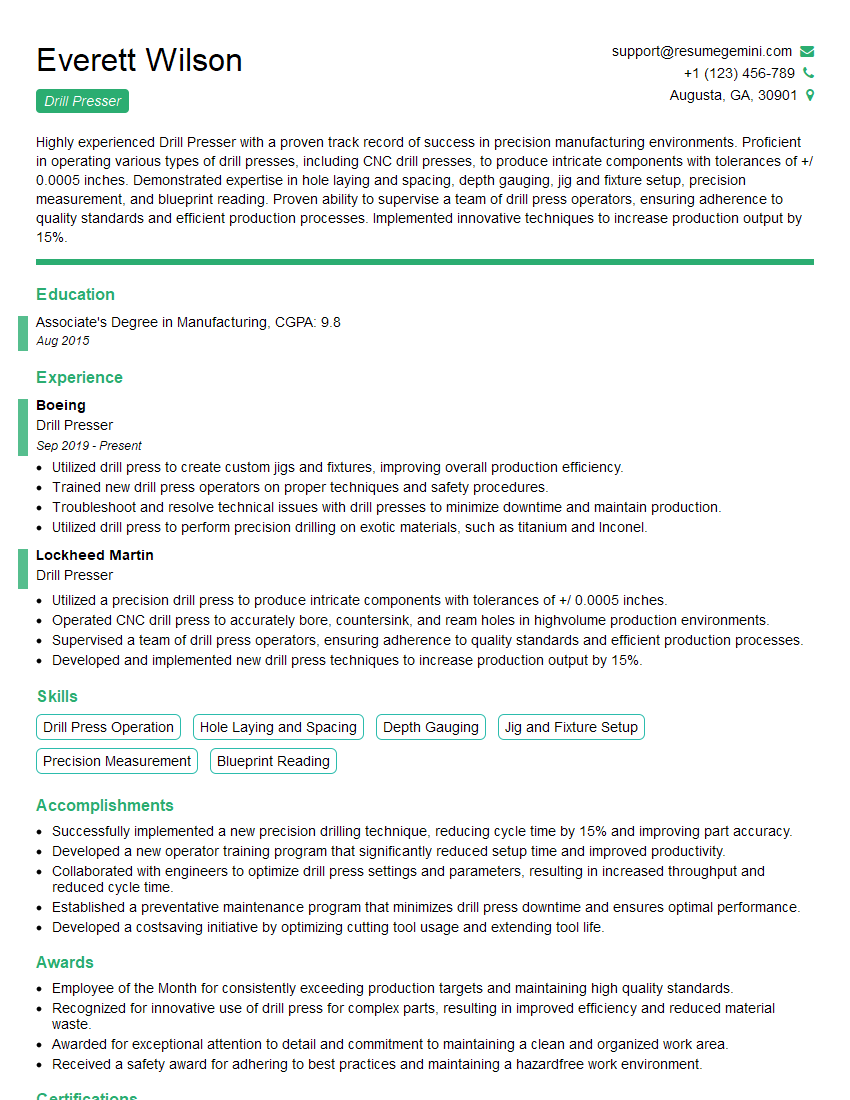

Everett Wilson

Drill Presser

Summary

Highly experienced Drill Presser with a proven track record of success in precision manufacturing environments. Proficient in operating various types of drill presses, including CNC drill presses, to produce intricate components with tolerances of +/ 0.0005 inches. Demonstrated expertise in hole laying and spacing, depth gauging, jig and fixture setup, precision measurement, and blueprint reading. Proven ability to supervise a team of drill press operators, ensuring adherence to quality standards and efficient production processes. Implemented innovative techniques to increase production output by 15%.

Education

Associate’s Degree in Manufacturing

August 2015

Skills

- Drill Press Operation

- Hole Laying and Spacing

- Depth Gauging

- Jig and Fixture Setup

- Precision Measurement

- Blueprint Reading

Work Experience

Drill Presser

- Utilized drill press to create custom jigs and fixtures, improving overall production efficiency.

- Trained new drill press operators on proper techniques and safety procedures.

- Troubleshoot and resolve technical issues with drill presses to minimize downtime and maintain production.

- Utilized drill press to perform precision drilling on exotic materials, such as titanium and Inconel.

Drill Presser

- Utilized a precision drill press to produce intricate components with tolerances of +/ 0.0005 inches.

- Operated CNC drill press to accurately bore, countersink, and ream holes in highvolume production environments.

- Supervised a team of drill press operators, ensuring adherence to quality standards and efficient production processes.

- Developed and implemented new drill press techniques to increase production output by 15%.

Accomplishments

- Successfully implemented a new precision drilling technique, reducing cycle time by 15% and improving part accuracy.

- Developed a new operator training program that significantly reduced setup time and improved productivity.

- Collaborated with engineers to optimize drill press settings and parameters, resulting in increased throughput and reduced cycle time.

- Established a preventative maintenance program that minimizes drill press downtime and ensures optimal performance.

- Developed a costsaving initiative by optimizing cutting tool usage and extending tool life.

Awards

- Employee of the Month for consistently exceeding production targets and maintaining high quality standards.

- Recognized for innovative use of drill press for complex parts, resulting in improved efficiency and reduced material waste.

- Awarded for exceptional attention to detail and commitment to maintaining a clean and organized work area.

- Received a safety award for adhering to best practices and maintaining a hazardfree work environment.

Certificates

- Drill Press Operator Certification

- Precision Measurement Certification

- Quality Control Certification

- Safety Procedures Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Drill Presser

- Quantify your accomplishments whenever possible.

- Use action verbs to describe your skills and experience.

- Tailor your resume to each specific job you apply for.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Drill Presser Resume

- Operated precision drill press to produce intricate components with tolerances of +/ 0.0005 inches.

- Utilized CNC drill press to accurately bore, countersink, and ream holes in high-volume production environments.

- Supervised a team of drill press operators, ensuring adherence to quality standards and efficient production processes.

- Developed and implemented new drill press techniques to increase production output by 15%.

- Utilized drill press to create custom jigs and fixtures, improving overall production efficiency.

- Trained new drill press operators on proper techniques and safety procedures.

- Troubleshoot and resolve technical issues with drill presses to minimize downtime and maintain production.

Frequently Asked Questions (FAQ’s) For Drill Presser

What are the key skills required to be a successful Drill Presser?

The key skills required to be a successful Drill Presser include precision measurement, blueprint reading, depth gauging, and jig and fixture setup. In addition, experience with CNC drill presses is preferred.

What are the typical job responsibilities of a Drill Presser?

The typical job responsibilities of a Drill Presser include operating drill presses to create holes in various materials, setting up and operating jigs and fixtures, and maintaining drill presses and related equipment.

What are the career prospects for Drill Pressers?

Drill Pressers with experience and expertise can advance to supervisory roles, such as Lead Drill Presser or Machine Shop Supervisor. Additionally, they may also pursue careers in other areas of manufacturing, such as quality control or production planning.

What are the educational requirements for becoming a Drill Presser?

While there are no formal educational requirements for becoming a Drill Presser, most employers prefer candidates with a high school diploma or equivalent. Some employers may also require candidates to have completed an apprenticeship program or have experience working in a machine shop.

What are the safety precautions that Drill Pressers must follow?

Drill Pressers must follow various safety precautions, such as wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs. They must also be aware of the potential hazards associated with operating drill presses, such as rotating machinery, sharp edges, and flying debris.

What are the different types of drill presses that Drill Pressers may use?

Drill Pressers may use various types of drill presses, including benchtop drill presses, floor drill presses, and CNC drill presses. Each type of drill press has its own unique features and capabilities.

What are the common materials that Drill Pressers work with?

Drill Pressers commonly work with various materials, such as metal, wood, and plastic. They may also work with other materials, such as composites and ceramics, depending on the specific job requirements.

What are the essential tools that Drill Pressers use?

Drill Pressers use various essential tools, such as drill bits, cutting fluids, and measuring tools. They may also use specialized tools, such as jigs and fixtures, depending on the specific job requirements.