Are you a seasoned Drop Forger seeking a new career path? Discover our professionally built Drop Forger Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

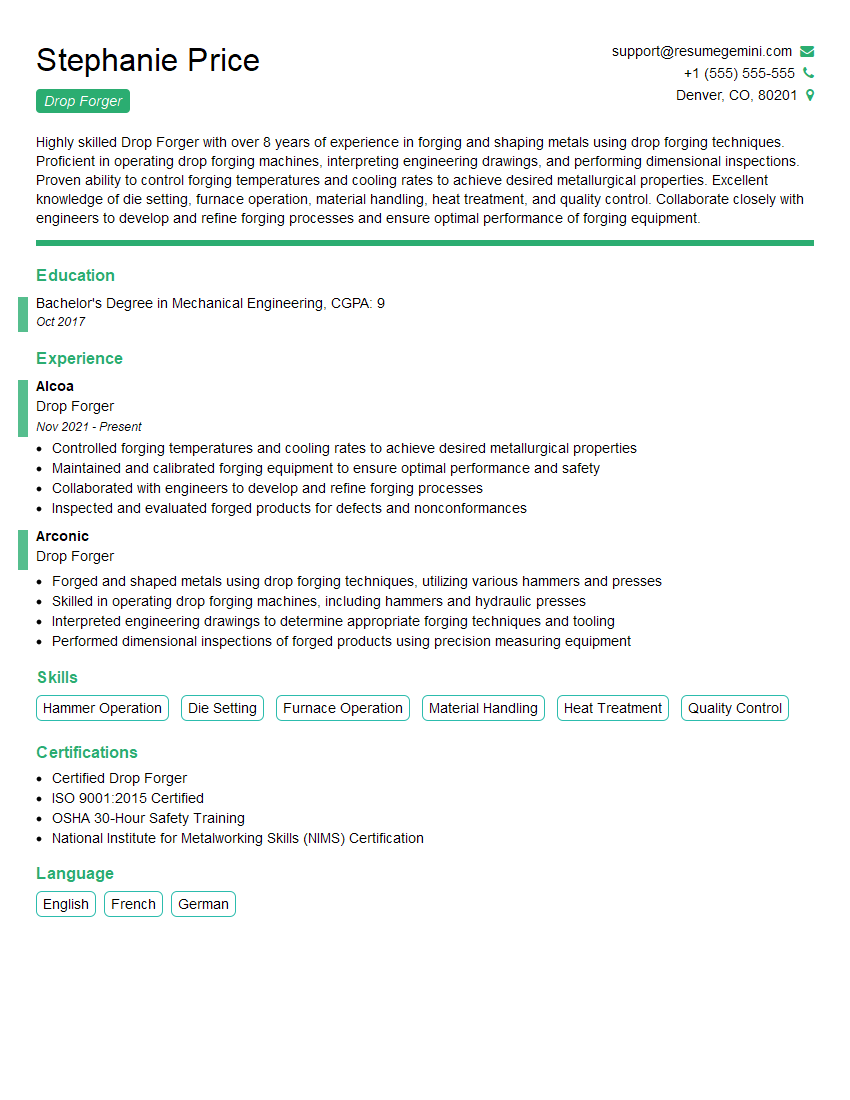

Stephanie Price

Drop Forger

Summary

Highly skilled Drop Forger with over 8 years of experience in forging and shaping metals using drop forging techniques. Proficient in operating drop forging machines, interpreting engineering drawings, and performing dimensional inspections. Proven ability to control forging temperatures and cooling rates to achieve desired metallurgical properties. Excellent knowledge of die setting, furnace operation, material handling, heat treatment, and quality control. Collaborate closely with engineers to develop and refine forging processes and ensure optimal performance of forging equipment.

Education

Bachelor’s Degree in Mechanical Engineering

October 2017

Skills

- Hammer Operation

- Die Setting

- Furnace Operation

- Material Handling

- Heat Treatment

- Quality Control

Work Experience

Drop Forger

- Controlled forging temperatures and cooling rates to achieve desired metallurgical properties

- Maintained and calibrated forging equipment to ensure optimal performance and safety

- Collaborated with engineers to develop and refine forging processes

- Inspected and evaluated forged products for defects and nonconformances

Drop Forger

- Forged and shaped metals using drop forging techniques, utilizing various hammers and presses

- Skilled in operating drop forging machines, including hammers and hydraulic presses

- Interpreted engineering drawings to determine appropriate forging techniques and tooling

- Performed dimensional inspections of forged products using precision measuring equipment

Certificates

- Certified Drop Forger

- ISO 9001:2015 Certified

- OSHA 30-Hour Safety Training

- National Institute for Metalworking Skills (NIMS) Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Drop Forger

Highlight your technical skills:

Emphasize your proficiency in drop forging techniques, hammer operation, and die setting. Quantify your experience by providing specific examples of the parts you have forged and the tolerances you have achieved.Showcase your quality control experience:

Drop forgers are responsible for ensuring the quality of their products. Highlight your experience in performing dimensional inspections, controlling forging temperatures, and maintaining forging equipment.Demonstrate your teamwork and communication skills:

Drop forgers often work with engineers and other team members to develop and refine forging processes. Highlight your experience in collaborating with others and your ability to communicate technical information effectively.Include relevant keywords:

When writing your resume, be sure to include relevant keywords that potential employers will be searching for, such as “drop forging,” “hammer operation,” and “quality control.”

Essential Experience Highlights for a Strong Drop Forger Resume

- Forged and shaped metals using drop forging techniques, utilizing various hammers and presses

- Skilled in operating drop forging machines, including hammers and hydraulic presses

- Interpreted engineering drawings to determine appropriate forging techniques and tooling

- Performed dimensional inspections of forged products using precision measuring equipment

- Controlled forging temperatures and cooling rates to achieve desired metallurgical properties

- Maintained and calibrated forging equipment to ensure optimal performance and safety

- Collaborated with engineers to develop and refine forging processes

Frequently Asked Questions (FAQ’s) For Drop Forger

What is drop forging?

Drop forging is a metalworking process that uses a hammer or press to shape metal by repeatedly striking it with a die.

What are the different types of drop forging machines?

There are two main types of drop forging machines: gravity drop hammers and power drop hammers. Gravity drop hammers use the force of gravity to strike the metal, while power drop hammers use a mechanical power source.

What are the advantages of drop forging?

Drop forging produces parts that are strong, durable, and have excellent dimensional accuracy. It is also a relatively fast and efficient process.

What are the disadvantages of drop forging?

Drop forging can be a noisy and hazardous process. It can also be expensive to set up and maintain a drop forging operation.

What is the difference between drop forging and press forging?

Drop forging uses a hammer or press to shape metal, while press forging uses a press to apply pressure to the metal. Drop forging produces parts that are stronger and more durable than press forged parts, but it is also a more expensive process.

What are the career opportunities for drop forgers?

Drop forgers can work in a variety of industries, including automotive, aerospace, and construction. They can also work in research and development, or as quality control inspectors.

What is the salary range for drop forgers?

The salary range for drop forgers varies depending on their experience, skills, and location. According to Salary.com, the average salary for a drop forger in the United States is $45,000 per year.