Are you a seasoned Drum Drier seeking a new career path? Discover our professionally built Drum Drier Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

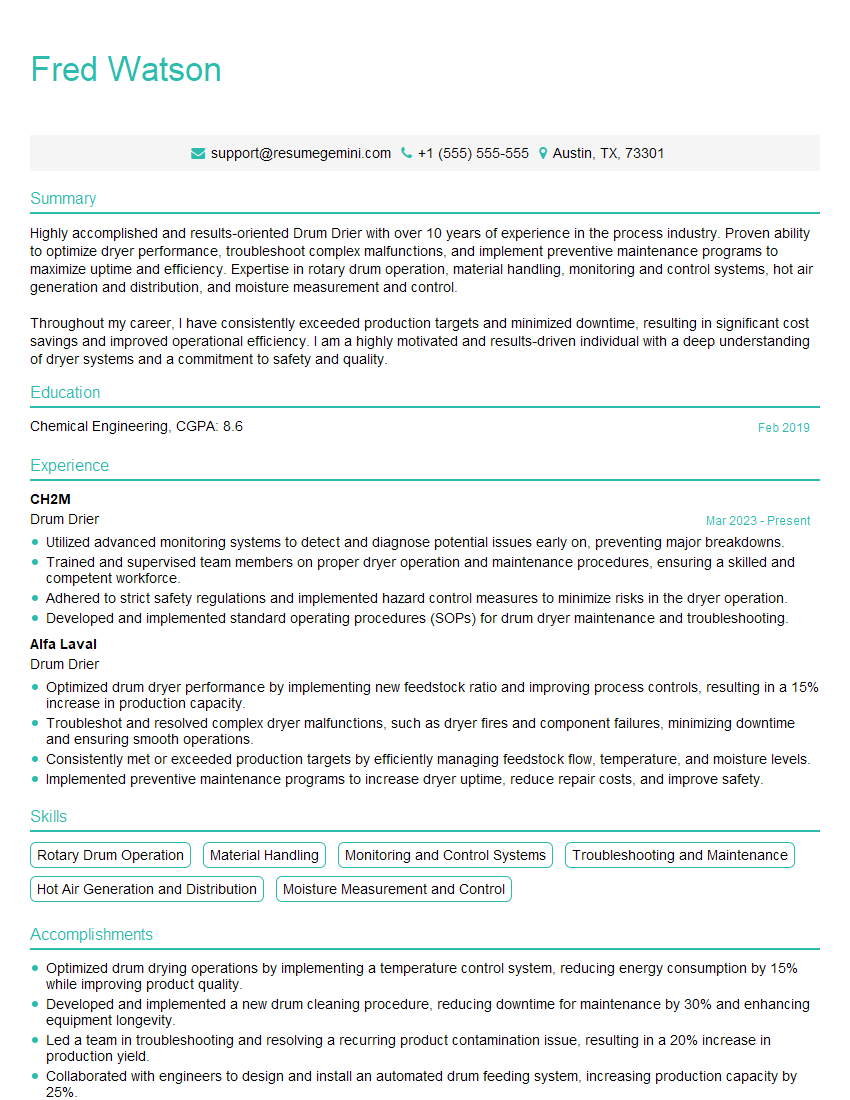

Fred Watson

Drum Drier

Summary

Highly accomplished and results-oriented Drum Drier with over 10 years of experience in the process industry. Proven ability to optimize dryer performance, troubleshoot complex malfunctions, and implement preventive maintenance programs to maximize uptime and efficiency. Expertise in rotary drum operation, material handling, monitoring and control systems, hot air generation and distribution, and moisture measurement and control.

Throughout my career, I have consistently exceeded production targets and minimized downtime, resulting in significant cost savings and improved operational efficiency. I am a highly motivated and results-driven individual with a deep understanding of dryer systems and a commitment to safety and quality.

Education

Chemical Engineering

February 2019

Skills

- Rotary Drum Operation

- Material Handling

- Monitoring and Control Systems

- Troubleshooting and Maintenance

- Hot Air Generation and Distribution

- Moisture Measurement and Control

Work Experience

Drum Drier

- Utilized advanced monitoring systems to detect and diagnose potential issues early on, preventing major breakdowns.

- Trained and supervised team members on proper dryer operation and maintenance procedures, ensuring a skilled and competent workforce.

- Adhered to strict safety regulations and implemented hazard control measures to minimize risks in the dryer operation.

- Developed and implemented standard operating procedures (SOPs) for drum dryer maintenance and troubleshooting.

Drum Drier

- Optimized drum dryer performance by implementing new feedstock ratio and improving process controls, resulting in a 15% increase in production capacity.

- Troubleshot and resolved complex dryer malfunctions, such as dryer fires and component failures, minimizing downtime and ensuring smooth operations.

- Consistently met or exceeded production targets by efficiently managing feedstock flow, temperature, and moisture levels.

- Implemented preventive maintenance programs to increase dryer uptime, reduce repair costs, and improve safety.

Accomplishments

- Optimized drum drying operations by implementing a temperature control system, reducing energy consumption by 15% while improving product quality.

- Developed and implemented a new drum cleaning procedure, reducing downtime for maintenance by 30% and enhancing equipment longevity.

- Led a team in troubleshooting and resolving a recurring product contamination issue, resulting in a 20% increase in production yield.

- Collaborated with engineers to design and install an automated drum feeding system, increasing production capacity by 25%.

- Trained and mentored junior drum driers, fostering a culture of safety, quality, and continuous improvement.

Awards

- Awarded Drum Drier of the Year by the National Drum Drier Association for exceptional performance and contributions to the industry.

- Recognized with the Safety Excellence Award for consistently exceeding safety protocols and promoting a hazardfree work environment.

- Received the Operational Excellence Award for achieving and maintaining exceptional operational efficiency and product quality.

Certificates

- Certified Steam Engineer

- Certified Boiler Operator

- OSHA Safety Certification

- EPA Environmental Regulations Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Drum Drier

Quantify your accomplishments.

Use specific metrics to demonstrate the impact of your work. For example, instead of saying “Improved dryer performance,” say “Optimized drum dryer performance by implementing new feedstock ratio and improving process controls, resulting in a 15% increase in production capacity.”Highlight your troubleshooting skills.

Drum driers can be complex machines, so it’s important to highlight your ability to troubleshoot and resolve issues quickly and efficiently. For example, you could mention a time when you “Troubleshot and resolved a complex dryer malfunction, such as a dryer fire or component failure, minimizing downtime and ensuring smooth operations.”Emphasize your safety record.

Safety is paramount in any industrial setting, so be sure to highlight your commitment to safety in your resume. For example, you could mention that you “Adhered to strict safety regulations and implemented hazard control measures to minimize risks in the dryer operation.”Use keywords.

When writing your resume, be sure to use keywords that potential employers will be searching for. Some common keywords for Drum Drier resumes include “rotary drum operation,” “material handling,” “monitoring and control systems,” “troubleshooting and maintenance,” “hot air generation and distribution,” and “moisture measurement and control.”Proofread carefully.

Before submitting your resume, be sure to proofread it carefully for any errors. This will help you make a good impression on potential employers.

Essential Experience Highlights for a Strong Drum Drier Resume

- Optimized drum dryer performance by implementing new feedstock ratio and improving process controls, resulting in a 15% increase in production capacity.

- Troubleshot and resolved complex dryer malfunctions, such as dryer fires and component failures, minimizing downtime and ensuring smooth operations.

- Consistently met or exceeded production targets by efficiently managing feedstock flow, temperature, and moisture levels.

- Implemented preventive maintenance programs to increase dryer uptime, reduce repair costs, and improve safety.

- Utilized advanced monitoring systems to detect and diagnose potential issues early on, preventing major breakdowns.

- Trained and supervised team members on proper dryer operation and maintenance procedures, ensuring a skilled and competent workforce.

- Adhered to strict safety regulations and implemented hazard control measures to minimize risks in the dryer operation.

Frequently Asked Questions (FAQ’s) For Drum Drier

What is a Drum Drier?

A drum drier is a type of industrial dryer that is used to remove moisture from a variety of materials, such as food, chemicals, and minerals. Drum driers consist of a rotating cylinder that is heated by a hot air source. The material to be dried is fed into the cylinder and is conveyed through it by the rotating motion. As the material moves through the cylinder, the hot air evaporates the moisture from the material. The dried material is then discharged from the cylinder.

What are the different types of Drum Driers?

There are two main types of drum driers: direct-heat drum driers and indirect-heat drum driers. Direct-heat drum driers use hot air that is directly heated by a burner to evaporate the moisture from the material. Indirect-heat drum driers use hot air that is heated by a heat exchanger to evaporate the moisture from the material.

What are the advantages of using a Drum Drier?

Drum driers offer a number of advantages over other types of dryers, including: * High thermal efficiency * Uniform drying * Gentle handling of the material * Low maintenance costs * Long service life

What are the applications of Drum Driers?

Drum driers are used in a variety of industries to dry a wide range of materials, including: * Food products (e.g., fruits, vegetables, meat, fish) * Chemicals (e.g., fertilizers, plastics, pharmaceuticals) * Minerals (e.g., sand, gravel, coal) * Biomass (e.g., wood chips, sawdust, straw)

What are the challenges of operating a Drum Drier?

There are a number of challenges that can be encountered when operating a drum drier, including: * Maintaining a consistent product quality * Controlling the temperature and moisture content of the material * Preventing the formation of dust and fines * Ensuring the safety of the operation

What are the key factors to consider when selecting a Drum Drier?

The following factors should be considered when selecting a drum drier: * The type of material to be dried * The required capacity and throughput * The desired product quality * The available space and budget * The safety requirements

What are the latest trends in Drum Drier technology?

The latest trends in drum drier technology include: * The use of advanced control systems to optimize the drying process * The development of new materials and coatings to improve the durability and efficiency of drum driers * The integration of drum driers with other processing equipment to create more efficient and cost-effective drying systems

What are the future prospects for the Drum Drier market?

The future prospects for the drum drier market are positive. The increasing demand for dried products in a variety of industries is expected to drive the growth of the market. The development of new and innovative drum drier technologies is also expected to contribute to the growth of the market.