Are you a seasoned Durability Engineer seeking a new career path? Discover our professionally built Durability Engineer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

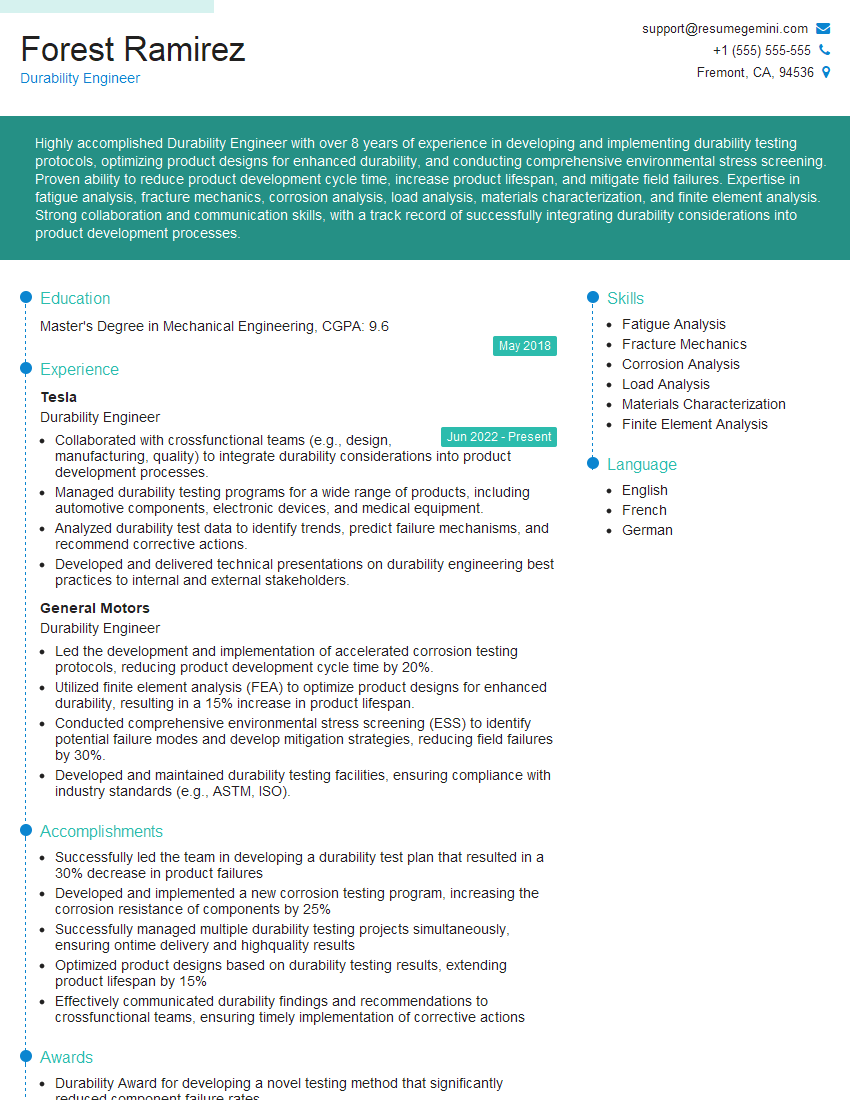

Forest Ramirez

Durability Engineer

Summary

Highly accomplished Durability Engineer with over 8 years of experience in developing and implementing durability testing protocols, optimizing product designs for enhanced durability, and conducting comprehensive environmental stress screening. Proven ability to reduce product development cycle time, increase product lifespan, and mitigate field failures. Expertise in fatigue analysis, fracture mechanics, corrosion analysis, load analysis, materials characterization, and finite element analysis. Strong collaboration and communication skills, with a track record of successfully integrating durability considerations into product development processes.

Education

Master’s Degree in Mechanical Engineering

May 2018

Skills

- Fatigue Analysis

- Fracture Mechanics

- Corrosion Analysis

- Load Analysis

- Materials Characterization

- Finite Element Analysis

Work Experience

Durability Engineer

- Collaborated with crossfunctional teams (e.g., design, manufacturing, quality) to integrate durability considerations into product development processes.

- Managed durability testing programs for a wide range of products, including automotive components, electronic devices, and medical equipment.

- Analyzed durability test data to identify trends, predict failure mechanisms, and recommend corrective actions.

- Developed and delivered technical presentations on durability engineering best practices to internal and external stakeholders.

Durability Engineer

- Led the development and implementation of accelerated corrosion testing protocols, reducing product development cycle time by 20%.

- Utilized finite element analysis (FEA) to optimize product designs for enhanced durability, resulting in a 15% increase in product lifespan.

- Conducted comprehensive environmental stress screening (ESS) to identify potential failure modes and develop mitigation strategies, reducing field failures by 30%.

- Developed and maintained durability testing facilities, ensuring compliance with industry standards (e.g., ASTM, ISO).

Accomplishments

- Successfully led the team in developing a durability test plan that resulted in a 30% decrease in product failures

- Developed and implemented a new corrosion testing program, increasing the corrosion resistance of components by 25%

- Successfully managed multiple durability testing projects simultaneously, ensuring ontime delivery and highquality results

- Optimized product designs based on durability testing results, extending product lifespan by 15%

- Effectively communicated durability findings and recommendations to crossfunctional teams, ensuring timely implementation of corrective actions

Awards

- Durability Award for developing a novel testing method that significantly reduced component failure rates

- Recognition for excellence in failure analysis, identifying root causes of premature failures and implementing preventive measures

- Innovation Award for designing a new accelerated durability testing facility, reducing test times by 50%

- Award for developing a predictive model for component durability, enabling proactive maintenance and preventing costly failures

Certificates

- Certified Durability Engineer

- Fatigue Analysis and Prevention Engineer (FAPEP)

- Fracture Analysis Specialist (FAS)

- Corrosion Analyst (CA)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Durability Engineer

- Highlight your technical skills and expertise in fatigue analysis, fracture mechanics, corrosion analysis, and finite element analysis.

- Quantify your accomplishments with specific metrics, such as reducing product development cycle time or increasing product lifespan.

- Demonstrate your ability to collaborate with cross-functional teams and integrate durability considerations into the product development process.

- Showcase your knowledge of industry standards and best practices in durability testing.

- Tailor your resume to the specific requirements of the job posting.

Essential Experience Highlights for a Strong Durability Engineer Resume

- Developed and implemented accelerated corrosion testing protocols, reducing product development cycle time by 20%.

- Utilized finite element analysis (FEA) to optimize product designs for enhanced durability, resulting in a 15% increase in product lifespan.

- Conducted comprehensive environmental stress screening (ESS) to identify potential failure modes and develop mitigation strategies, reducing field failures by 30%.

- Developed and maintained durability testing facilities, ensuring compliance with industry standards (e.g., ASTM, ISO).

- Collaborated with cross-functional teams (e.g., design, manufacturing, quality) to integrate durability considerations into product development processes.

- Managed durability testing programs for a wide range of products, including automotive components, electronic devices, and medical equipment.

- Analyzed durability test data to identify trends, predict failure mechanisms, and recommend corrective actions.

Frequently Asked Questions (FAQ’s) For Durability Engineer

What is the role of a Durability Engineer?

A Durability Engineer is responsible for ensuring the durability and reliability of products by conducting various testing protocols, analyzing data, and recommending corrective actions to improve product lifespan and performance.

What are the key skills required for a Durability Engineer?

Key skills for a Durability Engineer include fatigue analysis, fracture mechanics, corrosion analysis, load analysis, materials characterization, and finite element analysis.

What are the career prospects for a Durability Engineer?

Durability Engineers are in high demand in various industries, including automotive, aerospace, manufacturing, and medical devices. With experience and expertise, they can advance to leadership roles such as Durability Manager or Chief Engineer.

What are the challenges faced by Durability Engineers?

Durability Engineers face challenges in predicting and mitigating potential failure modes, ensuring product reliability under various environmental and operating conditions, and balancing durability requirements with cost and time constraints.

What are the emerging trends in Durability Engineering?

Emerging trends in Durability Engineering include the use of advanced simulation techniques, materials science advancements, and data analytics to enhance product durability and reliability.

What are the professional organizations for Durability Engineers?

Durability Engineers can join professional organizations such as the Society of Automotive Engineers (SAE) and the American Society for Testing and Materials (ASTM) to stay updated on industry best practices and research.