Are you a seasoned Dustless Operator seeking a new career path? Discover our professionally built Dustless Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

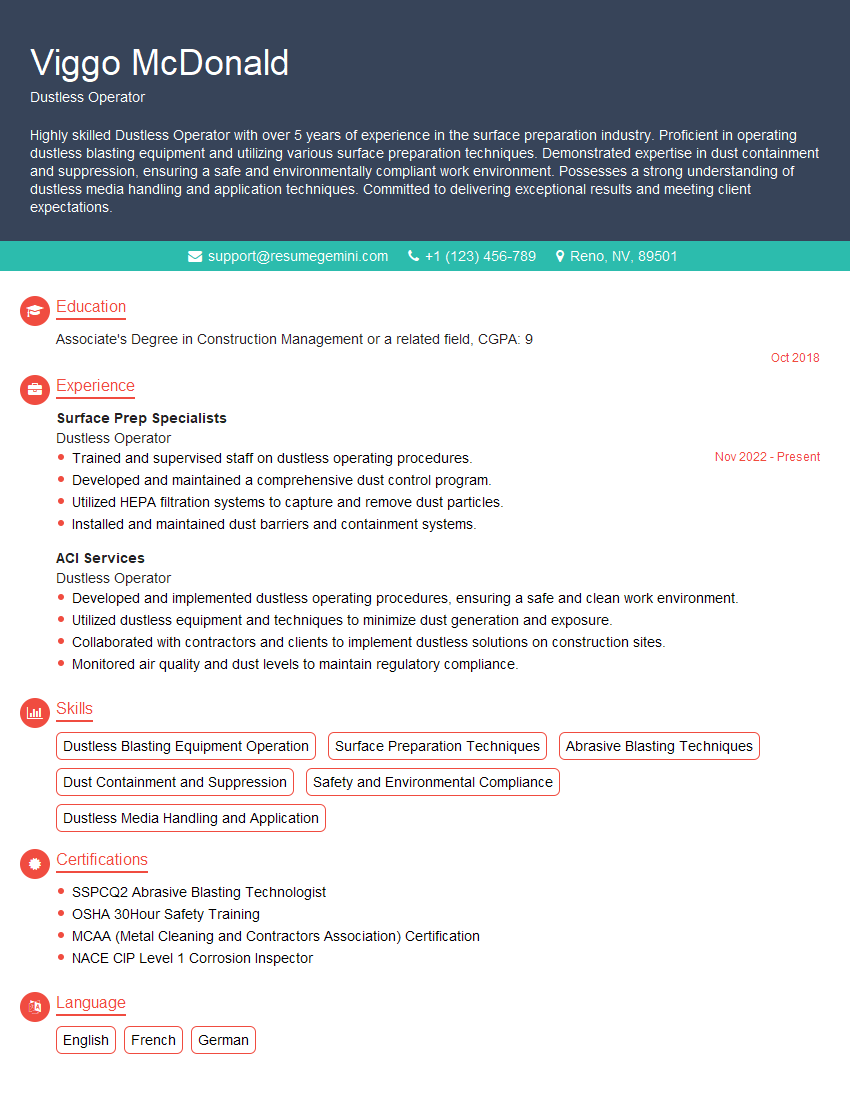

Viggo McDonald

Dustless Operator

Summary

Highly skilled Dustless Operator with over 5 years of experience in the surface preparation industry. Proficient in operating dustless blasting equipment and utilizing various surface preparation techniques. Demonstrated expertise in dust containment and suppression, ensuring a safe and environmentally compliant work environment. Possesses a strong understanding of dustless media handling and application techniques. Committed to delivering exceptional results and meeting client expectations.

Education

Associate’s Degree in Construction Management or a related field

October 2018

Skills

- Dustless Blasting Equipment Operation

- Surface Preparation Techniques

- Abrasive Blasting Techniques

- Dust Containment and Suppression

- Safety and Environmental Compliance

- Dustless Media Handling and Application

Work Experience

Dustless Operator

- Trained and supervised staff on dustless operating procedures.

- Developed and maintained a comprehensive dust control program.

- Utilized HEPA filtration systems to capture and remove dust particles.

- Installed and maintained dust barriers and containment systems.

Dustless Operator

- Developed and implemented dustless operating procedures, ensuring a safe and clean work environment.

- Utilized dustless equipment and techniques to minimize dust generation and exposure.

- Collaborated with contractors and clients to implement dustless solutions on construction sites.

- Monitored air quality and dust levels to maintain regulatory compliance.

Certificates

- SSPCQ2 Abrasive Blasting Technologist

- OSHA 30Hour Safety Training

- MCAA (Metal Cleaning and Contractors Association) Certification

- NACE CIP Level 1 Corrosion Inspector

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Dustless Operator

- Quantify your accomplishments using specific metrics and examples.

- Highlight your experience with specific dustless blasting equipment and techniques.

- Emphasize your commitment to safety and environmental compliance.

- Demonstrate your understanding of different surface preparation techniques and their applications.

Essential Experience Highlights for a Strong Dustless Operator Resume

- Operate dustless blasting equipment to remove coatings, rust, and other contaminants from various surfaces

- Implement surface preparation techniques to ensure optimal adhesion of new coatings or finishes

- Employ abrasive blasting techniques to achieve desired surface profiles and textures

- Utilize dust containment and suppression systems to minimize airborne dust and protect the environment

- Adhere to safety and environmental regulations and guidelines

- Maintain and inspect dustless blasting equipment to ensure optimal performance and safety

- Collaborate with other team members to prepare work areas and remove debris

Frequently Asked Questions (FAQ’s) For Dustless Operator

What is dustless blasting?

Dustless blasting is a surface preparation technique that uses a combination of abrasive media and water to remove coatings, rust, and other contaminants from surfaces while minimizing airborne dust.

What are the benefits of dustless blasting?

Dustless blasting offers several benefits, including improved visibility during the process, reduced cleanup time, and a cleaner work environment with minimal dust generation.

What industries use dustless blasting?

Dustless blasting finds applications in various industries, including construction, manufacturing, automotive, and restoration.

What are the safety considerations for dustless blasting?

Dustless blasting involves the use of abrasive media and water, so proper safety precautions are essential, including wearing appropriate protective gear, using dust containment systems, and following safety guidelines.

How do I become a Dustless Operator?

To become a Dustless Operator, you typically need a combination of on-the-job training, experience in surface preparation, and knowledge of dust containment techniques.

What are the career prospects for Dustless Operators?

Dustless Operators are in high demand in industries that require surface preparation services, and career prospects are generally positive with opportunities for advancement.

What are the key skills for Dustless Operators?

Key skills for Dustless Operators include proficiency in operating dustless blasting equipment, knowledge of surface preparation techniques, experience with dust containment systems, and adherence to safety regulations.