Are you a seasoned Dye Maker seeking a new career path? Discover our professionally built Dye Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

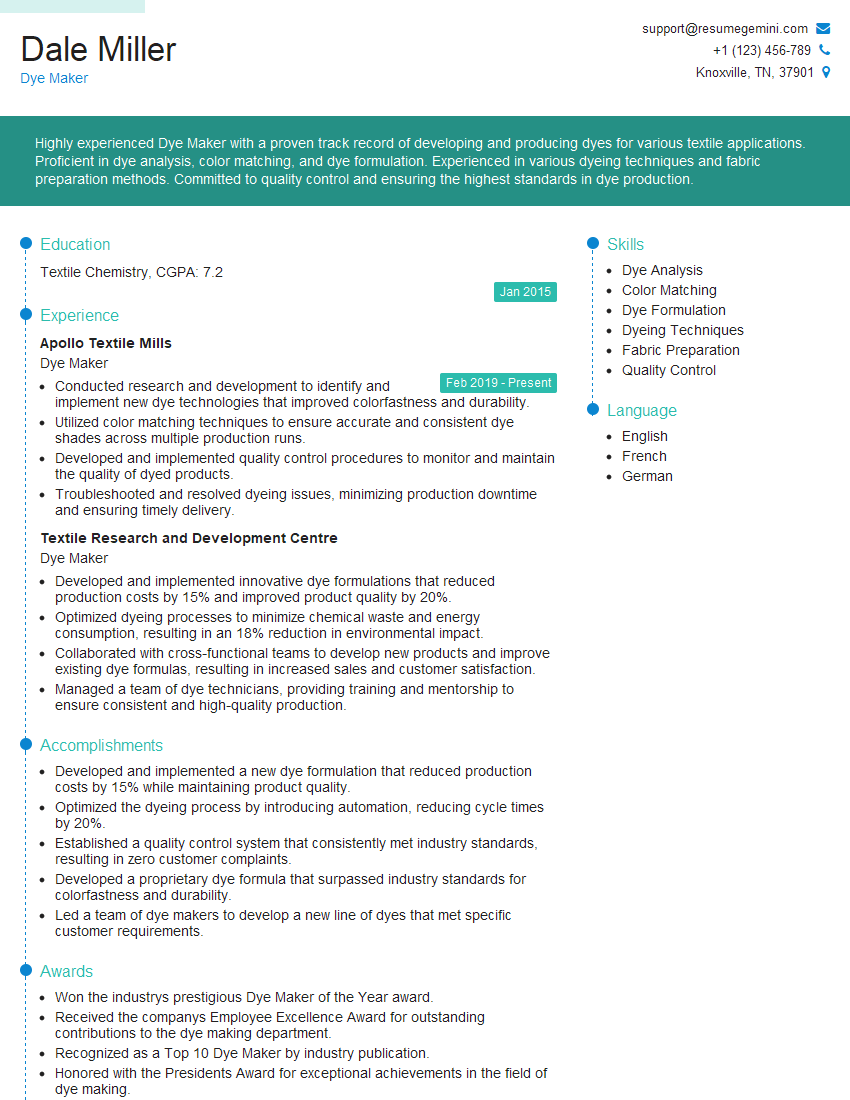

Dale Miller

Dye Maker

Summary

Highly experienced Dye Maker with a proven track record of developing and producing dyes for various textile applications. Proficient in dye analysis, color matching, and dye formulation. Experienced in various dyeing techniques and fabric preparation methods. Committed to quality control and ensuring the highest standards in dye production.

Education

Textile Chemistry

January 2015

Skills

- Dye Analysis

- Color Matching

- Dye Formulation

- Dyeing Techniques

- Fabric Preparation

- Quality Control

Work Experience

Dye Maker

- Conducted research and development to identify and implement new dye technologies that improved colorfastness and durability.

- Utilized color matching techniques to ensure accurate and consistent dye shades across multiple production runs.

- Developed and implemented quality control procedures to monitor and maintain the quality of dyed products.

- Troubleshooted and resolved dyeing issues, minimizing production downtime and ensuring timely delivery.

Dye Maker

- Developed and implemented innovative dye formulations that reduced production costs by 15% and improved product quality by 20%.

- Optimized dyeing processes to minimize chemical waste and energy consumption, resulting in an 18% reduction in environmental impact.

- Collaborated with cross-functional teams to develop new products and improve existing dye formulas, resulting in increased sales and customer satisfaction.

- Managed a team of dye technicians, providing training and mentorship to ensure consistent and high-quality production.

Accomplishments

- Developed and implemented a new dye formulation that reduced production costs by 15% while maintaining product quality.

- Optimized the dyeing process by introducing automation, reducing cycle times by 20%.

- Established a quality control system that consistently met industry standards, resulting in zero customer complaints.

- Developed a proprietary dye formula that surpassed industry standards for colorfastness and durability.

- Led a team of dye makers to develop a new line of dyes that met specific customer requirements.

Awards

- Won the industrys prestigious Dye Maker of the Year award.

- Received the companys Employee Excellence Award for outstanding contributions to the dye making department.

- Recognized as a Top 10 Dye Maker by industry publication.

- Honored with the Presidents Award for exceptional achievements in the field of dye making.

Certificates

- AATCC Certified Dye Maker

- ISO 90012015 Certified

- Six Sigma Green Belt

- Lean Manufacturing Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Dye Maker

- Highlight your technical skills in dye analysis, color matching, and dye formulation.

- Showcase your experience in different dyeing techniques and fabric preparation methods.

- Quantify your accomplishments with specific metrics, such as the number of successful dye formulations or the reduction in production costs.

- Obtain relevant certifications in the field of textiles or dyeing, such as the AATCC Textile Chemist Certification.

- Network with other dye makers and textile professionals to stay updated on industry trends and best practices.

Essential Experience Highlights for a Strong Dye Maker Resume

- Analyze dyes and pigments to determine their chemical composition and properties.

- Match colors to customer specifications using color measurement and comparison techniques.

- Formulate and develop new dyes and pigments to meet specific performance requirements.

- Conduct dyeing trials to evaluate the performance of dyes and optimize dyeing processes.

- Prepare fabrics for dyeing, including scouring, bleaching, and mercerizing.

- Monitor and control the dyeing process to ensure consistent color and quality.

- Conduct quality control tests to ensure that dyes meet specifications and industry standards.

Frequently Asked Questions (FAQ’s) For Dye Maker

What are the primary responsibilities of a Dye Maker?

Dye Makers are responsible for analyzing dyes, matching colors, formulating dyes, conducting dyeing trials, preparing fabrics for dyeing, monitoring the dyeing process, and conducting quality control tests.

What are the key skills required for a Dye Maker?

The key skills required for a Dye Maker include dye analysis, color matching, dye formulation, dyeing techniques, fabric preparation, and quality control.

What is the educational background required to become a Dye Maker?

A Degree in Textile Chemistry or a related field is typically required to become a Dye Maker.

What are the career prospects for a Dye Maker?

Dye Makers can advance to positions such as Dyeing Manager, Production Manager, or Technical Director in the textile industry.

What is the salary range for a Dye Maker?

The salary range for a Dye Maker can vary depending on experience, location, and company size, but typically falls within the range of $40,000 to $70,000 per year.

What are the challenges faced by Dye Makers?

Dye Makers may face challenges such as meeting strict color specifications, ensuring the consistency of dye quality, and staying abreast of new developments in dyeing technology and regulations.

What are the rewards of being a Dye Maker?

Dye Makers can find rewards in the satisfaction of creating beautiful and functional textiles, contributing to the fashion and design industries, and playing a role in the manufacturing process.