Are you a seasoned Electrical Discharge Machine Set Up Operator seeking a new career path? Discover our professionally built Electrical Discharge Machine Set Up Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

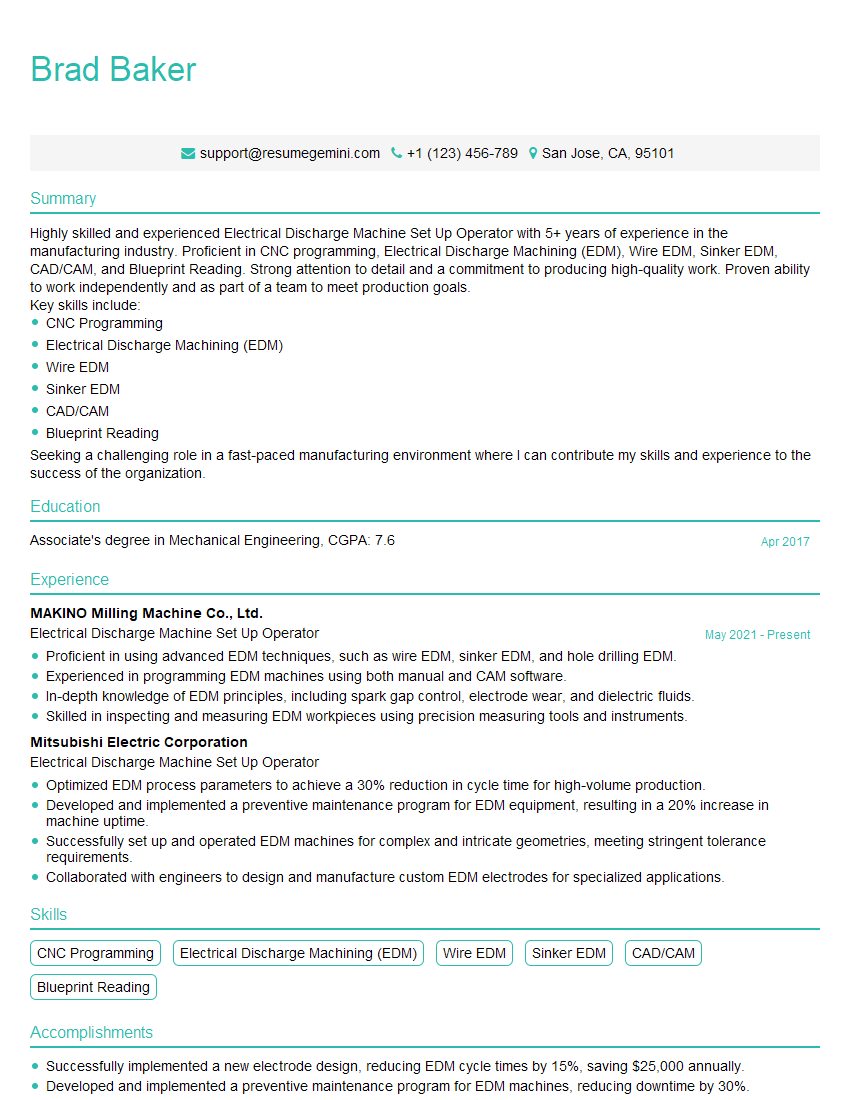

Brad Baker

Electrical Discharge Machine Set Up Operator

Summary

Highly skilled and experienced Electrical Discharge Machine Set Up Operator with 5+ years of experience in the manufacturing industry. Proficient in CNC programming, Electrical Discharge Machining (EDM), Wire EDM, Sinker EDM, CAD/CAM, and Blueprint Reading. Strong attention to detail and a commitment to producing high-quality work. Proven ability to work independently and as part of a team to meet production goals.

Key skills include:

- CNC Programming

- Electrical Discharge Machining (EDM)

- Wire EDM

- Sinker EDM

- CAD/CAM

- Blueprint Reading

Seeking a challenging role in a fast-paced manufacturing environment where I can contribute my skills and experience to the success of the organization.

Education

Associate’s degree in Mechanical Engineering

April 2017

Skills

- CNC Programming

- Electrical Discharge Machining (EDM)

- Wire EDM

- Sinker EDM

- CAD/CAM

- Blueprint Reading

Work Experience

Electrical Discharge Machine Set Up Operator

- Proficient in using advanced EDM techniques, such as wire EDM, sinker EDM, and hole drilling EDM.

- Experienced in programming EDM machines using both manual and CAM software.

- In-depth knowledge of EDM principles, including spark gap control, electrode wear, and dielectric fluids.

- Skilled in inspecting and measuring EDM workpieces using precision measuring tools and instruments.

Electrical Discharge Machine Set Up Operator

- Optimized EDM process parameters to achieve a 30% reduction in cycle time for high-volume production.

- Developed and implemented a preventive maintenance program for EDM equipment, resulting in a 20% increase in machine uptime.

- Successfully set up and operated EDM machines for complex and intricate geometries, meeting stringent tolerance requirements.

- Collaborated with engineers to design and manufacture custom EDM electrodes for specialized applications.

Accomplishments

- Successfully implemented a new electrode design, reducing EDM cycle times by 15%, saving $25,000 annually.

- Developed and implemented a preventive maintenance program for EDM machines, reducing downtime by 30%.

- Successfully trained new EDM operators, ensuring a 95% accuracy rate within 3 months.

- Identified and resolved a recurring problem with EDM surface finish, improving product quality by 12%.

- Developed a costeffective tooling system for EDM operations, reducing tooling expenses by 15%.

Awards

- Recognized for Excellence in EDM Setup Optimization, resulting in a 20% increase in production efficiency.

- Awarded for Outstanding Achievement in Precision EDM Machining, consistently meeting tightest tolerances.

- Recognized for Innovation in EDM Process Development, resulting in a 10% reduction in material waste.

- Awarded for Exceptional Customer Service, consistently exceeding customer expectations in EDMrelated inquiries.

Certificates

- Certified EDM Operator (CEO)

- CNC Programming Certificate

- Blueprint Reading Certificate

- Quality Control Certificate

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Electrical Discharge Machine Set Up Operator

Highlight your technical skills.

Be sure to list all of the relevant software and equipment that you are proficient in.Quantify your experience.

Whenever possible, use numbers to illustrate your accomplishments, such as the number of parts you have produced or the amount of time you have saved by improving processes.Proofread carefully.

Make sure that your resume is free of errors, both grammatical and factual.Tailor your resume to each job.

Take the time to customize your resume to match the specific requirements of each job you apply for.

Essential Experience Highlights for a Strong Electrical Discharge Machine Set Up Operator Resume

- Operate and set up electrical discharge machines (EDM) to produce precision parts and components according to engineering specifications.

- Program and operate CNC machines to control the movement of the EDM electrode during the machining process.

- Interpret blueprints and technical drawings to determine the required machining parameters and setup procedures.

- Monitor the machining process and make adjustments as needed to ensure accuracy and quality.

- Perform preventive maintenance and troubleshooting on EDM machines to minimize downtime and ensure optimal performance.

- Maintain a clean and organized work area and adhere to all safety protocols.

- Work closely with engineers and other team members to ensure that parts meet specifications and production schedules.

Frequently Asked Questions (FAQ’s) For Electrical Discharge Machine Set Up Operator

What is electrical discharge machining (EDM)?

Electrical discharge machining (EDM) is a manufacturing process that uses electrical discharges to remove material from a workpiece. The process is used to create precision parts and components with complex shapes and features.

What are the different types of EDM?

There are two main types of EDM: wire EDM and sinker EDM. Wire EDM uses a thin wire electrode to cut through the workpiece, while sinker EDM uses a shaped electrode to create the desired shape in the workpiece.

What are the advantages of using EDM?

EDM offers a number of advantages over traditional machining methods, including the ability to create complex shapes and features, the ability to machine hard materials, and the ability to achieve high precision.

What are the challenges of using EDM?

EDM can be a challenging process to control, and it can be difficult to achieve the desired surface finish. Additionally, EDM can be a slow process, and it can be expensive to set up and operate.

What are the applications of EDM?

EDM is used in a wide variety of applications, including the manufacture of medical devices, aerospace components, and automotive parts.

What is the future of EDM?

EDM is a rapidly growing technology, and it is expected to continue to play an important role in the manufacturing industry for many years to come.

How can I learn more about EDM?

There are a number of resources available to help you learn more about EDM, including online courses, books, and articles.

I am interested in a career as an EDM operator. What are the steps I need to take?

To become an EDM operator, you will need to have a strong understanding of the process and the equipment used. You can gain this knowledge through formal training or by working as an apprentice under an experienced EDM operator.