Are you a seasoned Electrical Discharge Machine Setup Operator seeking a new career path? Discover our professionally built Electrical Discharge Machine Setup Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

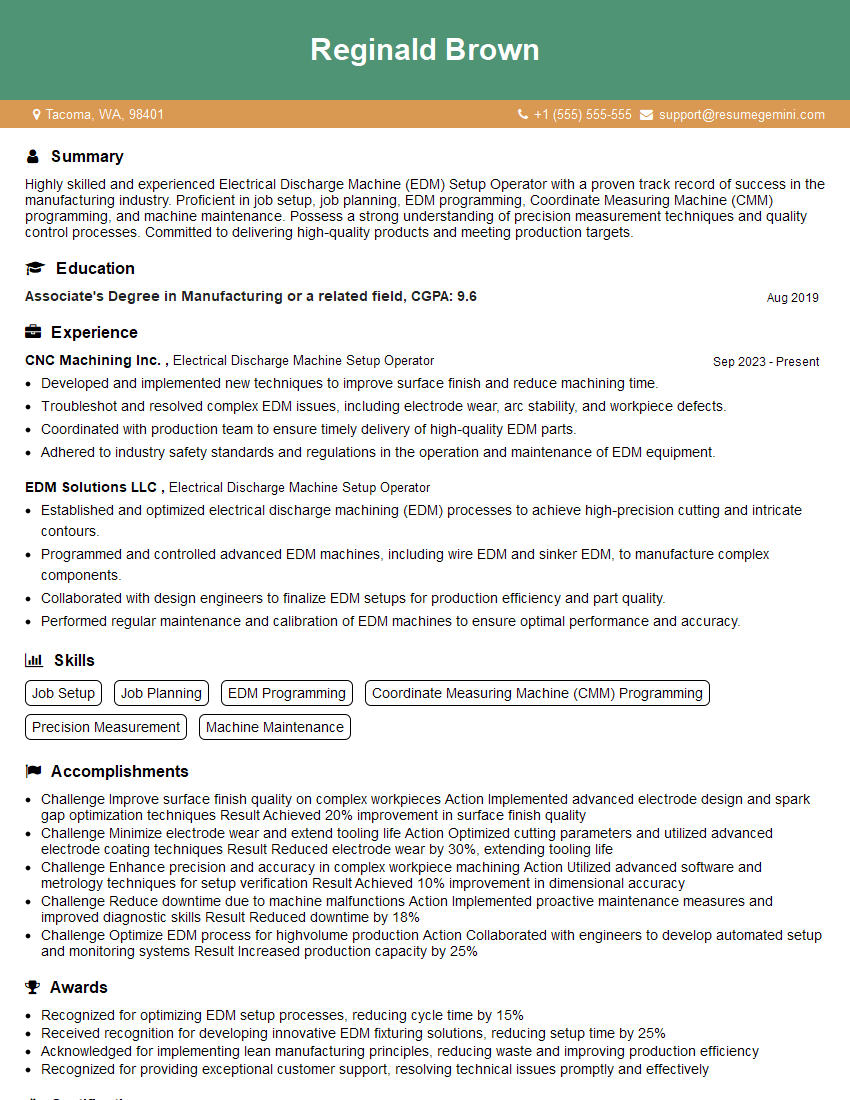

Reginald Brown

Electrical Discharge Machine Setup Operator

Summary

Highly skilled and experienced Electrical Discharge Machine (EDM) Setup Operator with a proven track record of success in the manufacturing industry. Proficient in job setup, job planning, EDM programming, Coordinate Measuring Machine (CMM) programming, and machine maintenance. Possess a strong understanding of precision measurement techniques and quality control processes. Committed to delivering high-quality products and meeting production targets.

Education

Associate’s Degree in Manufacturing or a related field

August 2019

Skills

- Job Setup

- Job Planning

- EDM Programming

- Coordinate Measuring Machine (CMM) Programming

- Precision Measurement

- Machine Maintenance

Work Experience

Electrical Discharge Machine Setup Operator

- Developed and implemented new techniques to improve surface finish and reduce machining time.

- Troubleshot and resolved complex EDM issues, including electrode wear, arc stability, and workpiece defects.

- Coordinated with production team to ensure timely delivery of high-quality EDM parts.

- Adhered to industry safety standards and regulations in the operation and maintenance of EDM equipment.

Electrical Discharge Machine Setup Operator

- Established and optimized electrical discharge machining (EDM) processes to achieve high-precision cutting and intricate contours.

- Programmed and controlled advanced EDM machines, including wire EDM and sinker EDM, to manufacture complex components.

- Collaborated with design engineers to finalize EDM setups for production efficiency and part quality.

- Performed regular maintenance and calibration of EDM machines to ensure optimal performance and accuracy.

Accomplishments

- Challenge Improve surface finish quality on complex workpieces Action Implemented advanced electrode design and spark gap optimization techniques Result Achieved 20% improvement in surface finish quality

- Challenge Minimize electrode wear and extend tooling life Action Optimized cutting parameters and utilized advanced electrode coating techniques Result Reduced electrode wear by 30%, extending tooling life

- Challenge Enhance precision and accuracy in complex workpiece machining Action Utilized advanced software and metrology techniques for setup verification Result Achieved 10% improvement in dimensional accuracy

- Challenge Reduce downtime due to machine malfunctions Action Implemented proactive maintenance measures and improved diagnostic skills Result Reduced downtime by 18%

- Challenge Optimize EDM process for highvolume production Action Collaborated with engineers to develop automated setup and monitoring systems Result Increased production capacity by 25%

Awards

- Recognized for optimizing EDM setup processes, reducing cycle time by 15%

- Received recognition for developing innovative EDM fixturing solutions, reducing setup time by 25%

- Acknowledged for implementing lean manufacturing principles, reducing waste and improving production efficiency

- Recognized for providing exceptional customer support, resolving technical issues promptly and effectively

Certificates

- Certified Electrical Discharge Machinist (CEDM)

- ISO 9001:2015 Certified

- AS9100 Certified

- ITAR Certified

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Electrical Discharge Machine Setup Operator

- Highlight your technical skills and experience in EDM machine setup and operation.

- Showcase your knowledge of EDM programming and CMM programming.

- Demonstrate your understanding of precision measurement techniques and quality control processes.

- Emphasize your ability to work independently and as part of a team in a fast-paced manufacturing environment.

Essential Experience Highlights for a Strong Electrical Discharge Machine Setup Operator Resume

- Set up and operate EDM machines according to engineering specifications.

- Develop and optimize EDM programs to ensure efficient and accurate machining.

- Inspect and measure workpieces using CMMs to verify dimensional accuracy.

- Maintain and troubleshoot EDM machines to ensure optimal performance.

- Monitor production processes and make adjustments to improve efficiency and quality.

- Collaborate with engineers and quality control personnel to ensure adherence to product specifications.

- Follow safety protocols and maintain a clean and organized work environment.

Frequently Asked Questions (FAQ’s) For Electrical Discharge Machine Setup Operator

What is the role of an Electrical Discharge Machine Setup Operator?

An Electrical Discharge Machine Setup Operator is responsible for setting up, operating, and maintaining EDM machines. They develop and optimize EDM programs, inspect and measure workpieces, and troubleshoot and maintain machines to ensure optimal performance.

What are the key skills required for an Electrical Discharge Machine Setup Operator?

Key skills for an Electrical Discharge Machine Setup Operator include job setup, job planning, EDM programming, Coordinate Measuring Machine (CMM) programming, precision measurement, and machine maintenance.

What is the job outlook for Electrical Discharge Machine Setup Operators?

The job outlook for Electrical Discharge Machine Setup Operators is expected to grow in the coming years due to the increasing demand for precision-machined components in various industries.

What are the career advancement opportunities for Electrical Discharge Machine Setup Operators?

Electrical Discharge Machine Setup Operators can advance their careers by becoming EDM programmers, quality control inspectors, or manufacturing engineers.

What is the average salary for Electrical Discharge Machine Setup Operators?

The average salary for Electrical Discharge Machine Setup Operators varies depending on experience, location, and industry. According to Indeed, the average salary for Electrical Discharge Machine Setup Operators in the United States is around $25 per hour.

What are the benefits of working as an Electrical Discharge Machine Setup Operator?

Benefits of working as an Electrical Discharge Machine Setup Operator include competitive salaries, job security, and opportunities for career advancement.

What are the challenges of working as an Electrical Discharge Machine Setup Operator?

Challenges of working as an Electrical Discharge Machine Setup Operator include working in a fast-paced environment, meeting tight deadlines, and working with potentially hazardous materials.

What is the work environment like for Electrical Discharge Machine Setup Operators?

Electrical Discharge Machine Setup Operators typically work in manufacturing facilities. They may work in a team environment or independently. The work environment can be noisy and dusty.