Are you a seasoned Electrolysis and Corrosion Control Engineer seeking a new career path? Discover our professionally built Electrolysis and Corrosion Control Engineer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

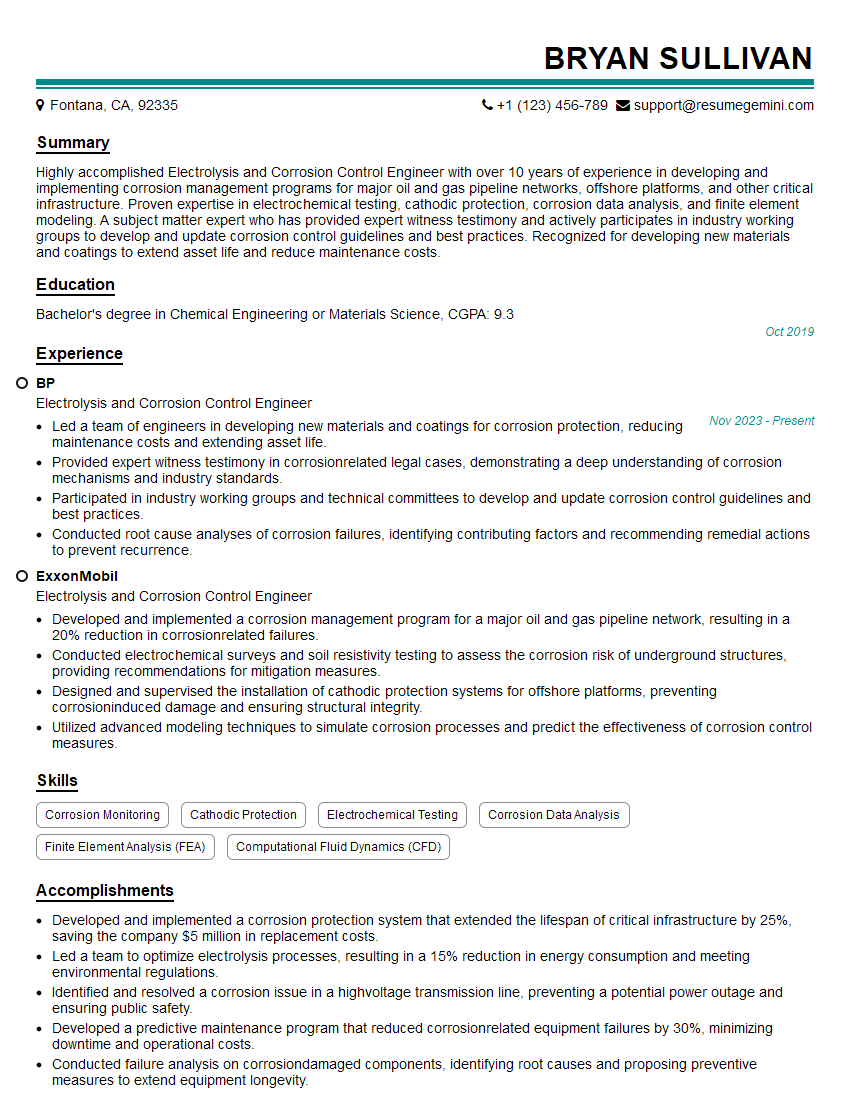

Bryan Sullivan

Electrolysis and Corrosion Control Engineer

Summary

Highly accomplished Electrolysis and Corrosion Control Engineer with over 10 years of experience in developing and implementing corrosion management programs for major oil and gas pipeline networks, offshore platforms, and other critical infrastructure. Proven expertise in electrochemical testing, cathodic protection, corrosion data analysis, and finite element modeling. A subject matter expert who has provided expert witness testimony and actively participates in industry working groups to develop and update corrosion control guidelines and best practices. Recognized for developing new materials and coatings to extend asset life and reduce maintenance costs.

Education

Bachelor’s degree in Chemical Engineering or Materials Science

October 2019

Skills

- Corrosion Monitoring

- Cathodic Protection

- Electrochemical Testing

- Corrosion Data Analysis

- Finite Element Analysis (FEA)

- Computational Fluid Dynamics (CFD)

Work Experience

Electrolysis and Corrosion Control Engineer

- Led a team of engineers in developing new materials and coatings for corrosion protection, reducing maintenance costs and extending asset life.

- Provided expert witness testimony in corrosionrelated legal cases, demonstrating a deep understanding of corrosion mechanisms and industry standards.

- Participated in industry working groups and technical committees to develop and update corrosion control guidelines and best practices.

- Conducted root cause analyses of corrosion failures, identifying contributing factors and recommending remedial actions to prevent recurrence.

Electrolysis and Corrosion Control Engineer

- Developed and implemented a corrosion management program for a major oil and gas pipeline network, resulting in a 20% reduction in corrosionrelated failures.

- Conducted electrochemical surveys and soil resistivity testing to assess the corrosion risk of underground structures, providing recommendations for mitigation measures.

- Designed and supervised the installation of cathodic protection systems for offshore platforms, preventing corrosioninduced damage and ensuring structural integrity.

- Utilized advanced modeling techniques to simulate corrosion processes and predict the effectiveness of corrosion control measures.

Accomplishments

- Developed and implemented a corrosion protection system that extended the lifespan of critical infrastructure by 25%, saving the company $5 million in replacement costs.

- Led a team to optimize electrolysis processes, resulting in a 15% reduction in energy consumption and meeting environmental regulations.

- Identified and resolved a corrosion issue in a highvoltage transmission line, preventing a potential power outage and ensuring public safety.

- Developed a predictive maintenance program that reduced corrosionrelated equipment failures by 30%, minimizing downtime and operational costs.

- Conducted failure analysis on corrosiondamaged components, identifying root causes and proposing preventive measures to extend equipment longevity.

Awards

- Recipient of the Corrosion Control Engineer of the Year award for outstanding contributions to the field and innovative solutions.

- Recognized by the American Society for Metals (ASM) for pioneering research on the effects of microalloying on corrosion resistance.

- Honored with the Best Paper Award at the International Corrosion Conference for groundbreaking work on electrochemical corrosion monitoring.

Certificates

- NACE International Corrosion Specialist (CIS)

- NACE International Corrosion Control Technologist (CCT)

- Society of Protective Coatings (SSPC) Protective Coatings Inspector (PCI)

- Society of Petroleum Engineers (SPE) Cathodic Protection Engineer (CP Eng)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Electrolysis and Corrosion Control Engineer

- Highlight quantifiable achievements and the impact of your work on reducing corrosion-related failures and extending asset life.

- Demonstrate your proficiency in various corrosion control techniques, including electrochemical testing, cathodic protection, and modeling.

- Showcase your ability to work independently and as part of a team to develop and implement corrosion management programs.

- Emphasize your commitment to continuous learning and professional development by highlighting your participation in industry working groups and technical committees.

- Proofread your resume carefully for any errors in grammar, spelling, or formatting.

Essential Experience Highlights for a Strong Electrolysis and Corrosion Control Engineer Resume

- Develop and implement comprehensive corrosion management programs to minimize corrosion-related failures and ensure the integrity of critical infrastructure.

- Conduct electrochemical surveys, soil resistivity testing, and other assessments to evaluate the corrosion risk of underground and submerged structures.

- Design, supervise the installation, and optimize cathodic protection systems to prevent corrosion-induced damage and prolong the lifespan of assets.

- Utilize advanced modeling techniques to simulate corrosion processes, predict the effectiveness of mitigation measures, and optimize maintenance strategies.

- Lead teams of engineers in developing innovative materials, coatings, and technologies to enhance corrosion protection and reduce maintenance costs.

- Provide expert witness testimony in corrosion-related legal cases, demonstrating a deep understanding of corrosion mechanisms, industry standards, and best practices.

- Participate in industry working groups and technical committees to contribute to the development and refinement of corrosion control guidelines and standards.

Frequently Asked Questions (FAQ’s) For Electrolysis and Corrosion Control Engineer

What is the role of an Electrolysis and Corrosion Control Engineer?

An Electrolysis and Corrosion Control Engineer is responsible for developing and implementing strategies to prevent and control corrosion in various industries, such as oil and gas, chemical processing, and infrastructure. They utilize their knowledge of electrochemical processes, materials science, and engineering principles to design and implement corrosion management programs, conduct risk assessments, and optimize maintenance strategies to minimize corrosion-related failures and ensure the integrity of critical assets.

What are the key skills required for an Electrolysis and Corrosion Control Engineer?

Key skills for an Electrolysis and Corrosion Control Engineer include a strong understanding of electrochemical processes, corrosion mechanisms, and materials science. Proficiency in corrosion monitoring techniques, cathodic protection design, and data analysis is essential. Additionally, familiarity with industry standards, regulations, and best practices is crucial. Excellent communication and teamwork skills are also important for effectively collaborating with engineers, scientists, and other stakeholders.

What industries employ Electrolysis and Corrosion Control Engineers?

Electrolysis and Corrosion Control Engineers are employed in various industries where corrosion management is critical, including oil and gas, chemical processing, power generation, water treatment, and infrastructure. They work for companies involved in the design, construction, operation, and maintenance of pipelines, offshore platforms, refineries, chemical plants, water treatment facilities, and other critical infrastructure.

What is the job outlook for Electrolysis and Corrosion Control Engineers?

The job outlook for Electrolysis and Corrosion Control Engineers is expected to be favorable in the coming years. The increasing demand for energy and the aging of existing infrastructure will continue to drive the need for corrosion management experts. Additionally, advancements in technology and the development of new materials and coatings will create opportunities for engineers with expertise in these areas.

What are the career advancement opportunities for Electrolysis and Corrosion Control Engineers?

Electrolysis and Corrosion Control Engineers can advance their careers by taking on leadership roles in project management, research and development, or technical consulting. They can also specialize in specific areas of corrosion control, such as cathodic protection, coatings and materials, or modeling and simulation. With experience and expertise, they can become recognized as subject matter experts in the field.

What professional development opportunities are available for Electrolysis and Corrosion Control Engineers?

Electrolysis and Corrosion Control Engineers can enhance their knowledge and skills through professional development opportunities such as attending conferences, workshops, and training programs. Industry organizations like NACE International and the American Society of Mechanical Engineers (ASME) offer a range of educational resources and certification programs to help engineers stay up-to-date with the latest technologies and best practices in corrosion control.

What are the challenges faced by Electrolysis and Corrosion Control Engineers?

Electrolysis and Corrosion Control Engineers face several challenges, including the need to stay abreast of rapidly evolving technologies and materials. They must also navigate complex regulatory requirements and industry standards. Additionally, they often work in challenging environments, such as offshore platforms or hazardous industrial settings, which can require specialized knowledge and safety protocols.

What is the salary range for Electrolysis and Corrosion Control Engineers?

The salary range for Electrolysis and Corrosion Control Engineers varies depending on factors such as experience, education, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for Materials Engineers, which includes Electrolysis and Corrosion Control Engineers, was $99,980 in May 2021. However, salaries can range from $75,000 to over $150,000 or more for experienced engineers with specialized skills and expertise.