Are you a seasoned Electroplating Laborer seeking a new career path? Discover our professionally built Electroplating Laborer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

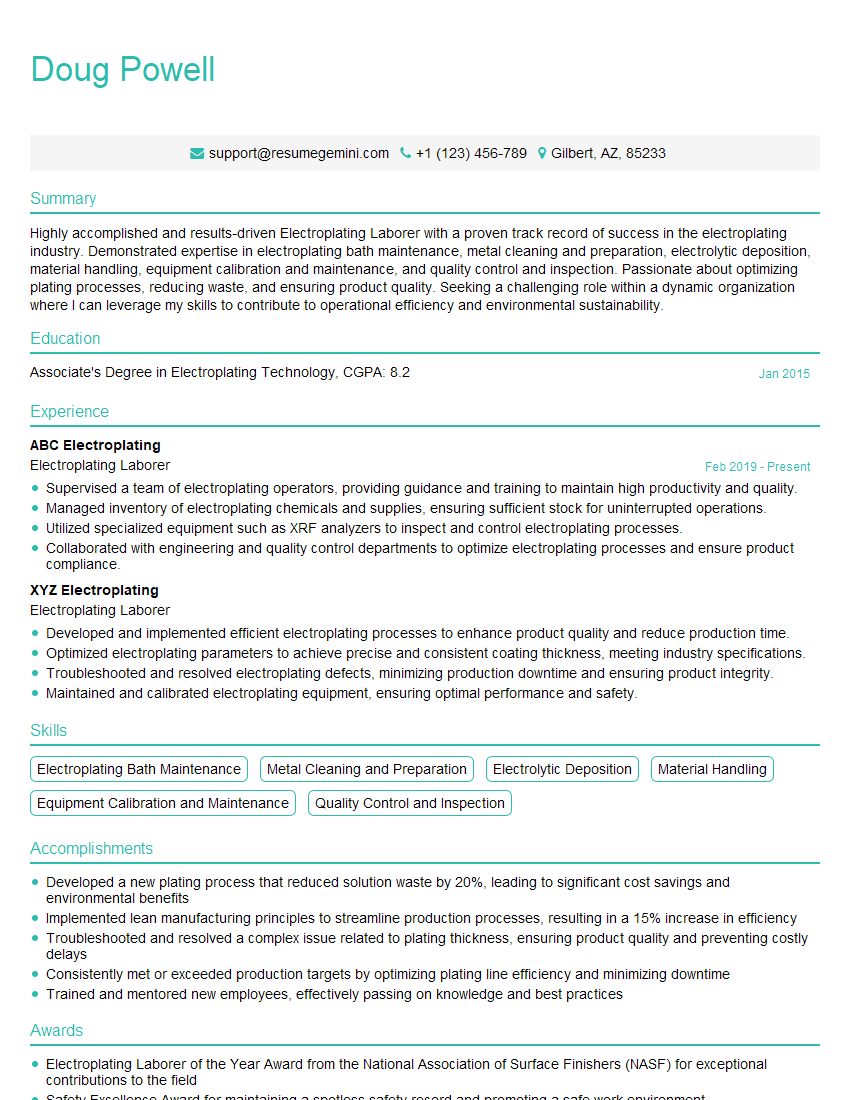

Doug Powell

Electroplating Laborer

Summary

Highly accomplished and results-driven Electroplating Laborer with a proven track record of success in the electroplating industry. Demonstrated expertise in electroplating bath maintenance, metal cleaning and preparation, electrolytic deposition, material handling, equipment calibration and maintenance, and quality control and inspection. Passionate about optimizing plating processes, reducing waste, and ensuring product quality. Seeking a challenging role within a dynamic organization where I can leverage my skills to contribute to operational efficiency and environmental sustainability.

Education

Associate’s Degree in Electroplating Technology

January 2015

Skills

- Electroplating Bath Maintenance

- Metal Cleaning and Preparation

- Electrolytic Deposition

- Material Handling

- Equipment Calibration and Maintenance

- Quality Control and Inspection

Work Experience

Electroplating Laborer

- Supervised a team of electroplating operators, providing guidance and training to maintain high productivity and quality.

- Managed inventory of electroplating chemicals and supplies, ensuring sufficient stock for uninterrupted operations.

- Utilized specialized equipment such as XRF analyzers to inspect and control electroplating processes.

- Collaborated with engineering and quality control departments to optimize electroplating processes and ensure product compliance.

Electroplating Laborer

- Developed and implemented efficient electroplating processes to enhance product quality and reduce production time.

- Optimized electroplating parameters to achieve precise and consistent coating thickness, meeting industry specifications.

- Troubleshooted and resolved electroplating defects, minimizing production downtime and ensuring product integrity.

- Maintained and calibrated electroplating equipment, ensuring optimal performance and safety.

Accomplishments

- Developed a new plating process that reduced solution waste by 20%, leading to significant cost savings and environmental benefits

- Implemented lean manufacturing principles to streamline production processes, resulting in a 15% increase in efficiency

- Troubleshooted and resolved a complex issue related to plating thickness, ensuring product quality and preventing costly delays

- Consistently met or exceeded production targets by optimizing plating line efficiency and minimizing downtime

- Trained and mentored new employees, effectively passing on knowledge and best practices

Awards

- Electroplating Laborer of the Year Award from the National Association of Surface Finishers (NASF) for exceptional contributions to the field

- Safety Excellence Award for maintaining a spotless safety record and promoting a safe work environment

- Recognized by the company for exceptional customer service and dedication to meeting customer needs

- Received a Quality Excellence Award for consistently producing highquality electroplated products

Certificates

- Electroplating Technician Certification

- Electroplating Basic Training Certification

- Workplace Safety and Health (OSHA)

- Hazardous Waste Management (EPA)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Electroplating Laborer

- Quantify your accomplishments with specific metrics to demonstrate your impact.

- Highlight your proficiency in lean manufacturing principles and how you have applied them to improve processes.

- Emphasize your ability to work effectively in a team environment and collaborate with colleagues.

- Showcase your commitment to safety and environmental compliance in the workplace.

Essential Experience Highlights for a Strong Electroplating Laborer Resume

- Maintain and optimize electroplating baths to ensure optimal plating conditions.

- Clean and prepare metal surfaces to enhance adhesion and plating quality.

- Operate electrolytic deposition equipment to apply specified coatings to various materials.

- Handle and store chemicals and materials safely and efficiently.

- Calibrate and maintain electroplating equipment to ensure accuracy and precision.

- Perform quality control inspections to verify adherence to specifications and standards.

- Troubleshoot and resolve plating issues to minimize downtime and maintain production efficiency.

Frequently Asked Questions (FAQ’s) For Electroplating Laborer

What is the role of an Electroplating Laborer?

An Electroplating Laborer is responsible for preparing, plating, and finishing metal surfaces using electroplating techniques. They maintain electroplating baths, clean and prepare metal surfaces, operate electrolytic deposition equipment, handle and store chemicals, calibrate and maintain equipment, perform quality control inspections, and troubleshoot plating issues.

What skills are required to be an Electroplating Laborer?

Electroplating Laborers typically have an Associate’s Degree in Electroplating Technology or a related field. They should have a strong understanding of electroplating principles, chemistry, and safety procedures. They should also be proficient in operating and maintaining electroplating equipment, handling chemicals, and performing quality control inspections.

What are the career prospects for Electroplating Laborers?

Electroplating Laborers can advance to supervisory roles, such as Electroplating Supervisor or Manager. With additional education and experience, they may also qualify for positions in research and development, quality control, or environmental compliance.

What is the work environment of an Electroplating Laborer like?

Electroplating Laborers typically work in industrial settings, such as electroplating shops or manufacturing facilities. They may work with chemicals, solvents, and other hazardous materials, so they must wear appropriate personal protective equipment and follow safety protocols.

What is the salary range for Electroplating Laborers?

The salary range for Electroplating Laborers varies depending on their experience, location, and employer. According to Indeed, the average salary for an Electroplating Laborer in the United States is around $50,000 per year.

What are the job opportunities for Electroplating Laborers?

Electroplating Laborers are employed in various industries, including automotive, aerospace, electronics, and jewelry. They may work for electroplating companies, manufacturers, or job shops. There is a growing demand for Electroplating Laborers due to the increasing use of electroplating in a wide range of applications.

What are the challenges faced by Electroplating Laborers?

Electroplating Laborers may face challenges related to safety, environmental compliance, and production efficiency. They must be aware of the hazards associated with working with chemicals and electricity and follow proper safety procedures. They must also be knowledgeable about environmental regulations and ensure that their work complies with these requirements. Additionally, Electroplating Laborers may face pressure to meet production targets while maintaining quality standards.