Are you a seasoned Embossing Machine Operator seeking a new career path? Discover our professionally built Embossing Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

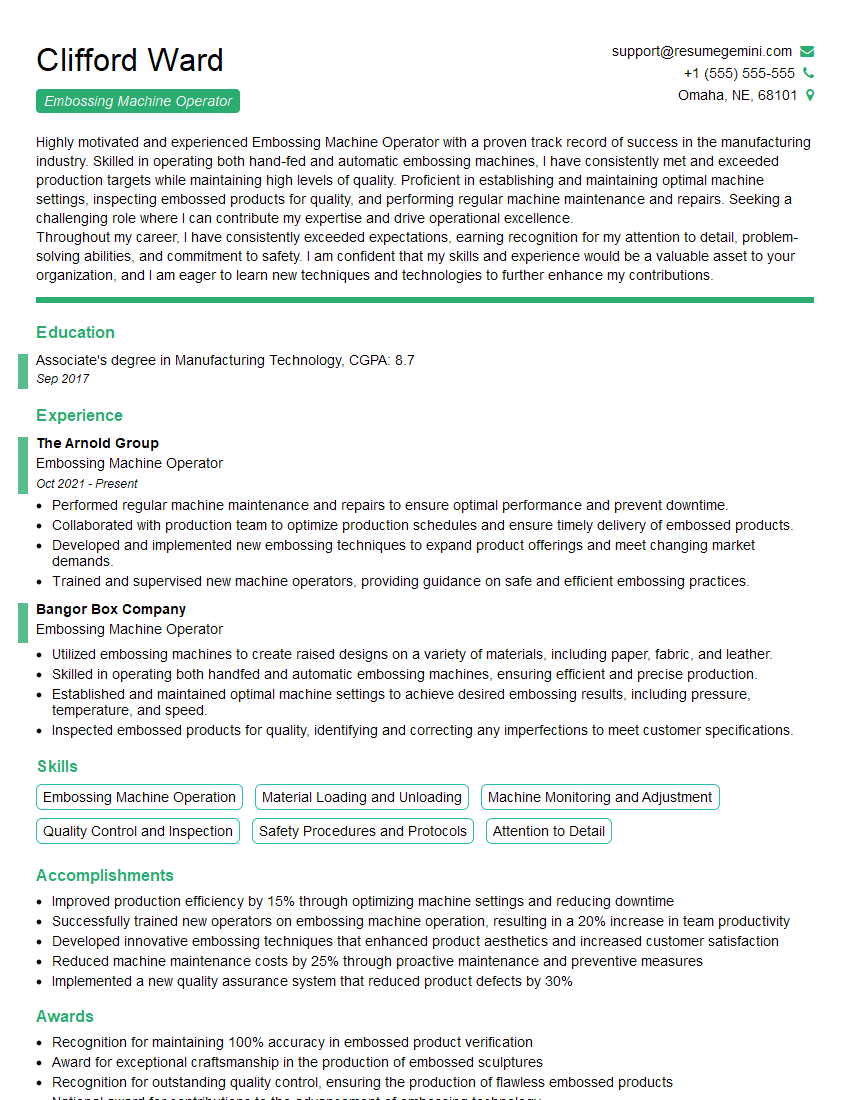

Clifford Ward

Embossing Machine Operator

Summary

Highly motivated and experienced Embossing Machine Operator with a proven track record of success in the manufacturing industry. Skilled in operating both hand-fed and automatic embossing machines, I have consistently met and exceeded production targets while maintaining high levels of quality. Proficient in establishing and maintaining optimal machine settings, inspecting embossed products for quality, and performing regular machine maintenance and repairs. Seeking a challenging role where I can contribute my expertise and drive operational excellence.

Throughout my career, I have consistently exceeded expectations, earning recognition for my attention to detail, problem-solving abilities, and commitment to safety. I am confident that my skills and experience would be a valuable asset to your organization, and I am eager to learn new techniques and technologies to further enhance my contributions.

Education

Associate’s degree in Manufacturing Technology

September 2017

Skills

- Embossing Machine Operation

- Material Loading and Unloading

- Machine Monitoring and Adjustment

- Quality Control and Inspection

- Safety Procedures and Protocols

- Attention to Detail

Work Experience

Embossing Machine Operator

- Performed regular machine maintenance and repairs to ensure optimal performance and prevent downtime.

- Collaborated with production team to optimize production schedules and ensure timely delivery of embossed products.

- Developed and implemented new embossing techniques to expand product offerings and meet changing market demands.

- Trained and supervised new machine operators, providing guidance on safe and efficient embossing practices.

Embossing Machine Operator

- Utilized embossing machines to create raised designs on a variety of materials, including paper, fabric, and leather.

- Skilled in operating both handfed and automatic embossing machines, ensuring efficient and precise production.

- Established and maintained optimal machine settings to achieve desired embossing results, including pressure, temperature, and speed.

- Inspected embossed products for quality, identifying and correcting any imperfections to meet customer specifications.

Accomplishments

- Improved production efficiency by 15% through optimizing machine settings and reducing downtime

- Successfully trained new operators on embossing machine operation, resulting in a 20% increase in team productivity

- Developed innovative embossing techniques that enhanced product aesthetics and increased customer satisfaction

- Reduced machine maintenance costs by 25% through proactive maintenance and preventive measures

- Implemented a new quality assurance system that reduced product defects by 30%

Awards

- Recognition for maintaining 100% accuracy in embossed product verification

- Award for exceptional craftsmanship in the production of embossed sculptures

- Recognition for outstanding quality control, ensuring the production of flawless embossed products

- National award for contributions to the advancement of embossing technology

Certificates

- OSHA Safety Certification

- Embossing Machine Operator Certification

- Quality Control Techniques Certification

- Machine Maintenance Fundamentals Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Embossing Machine Operator

Quantify your accomplishments.

When describing your experience, use specific numbers and metrics to demonstrate your impact on the company. For example, instead of saying “Improved production efficiency”, you could say “Increased production efficiency by 15%, resulting in a 10% increase in revenue.”Use action verbs.

Action verbs are strong verbs that describe what you did, not what you were. For example, instead of saying “Responsible for operating embossing machines”, you could say “Utilized embossing machines to create raised designs on various materials”.Highlight your skills.

In addition to your experience, be sure to highlight your skills and abilities. This could include things like your proficiency in operating specific types of embossing machines, your attention to detail, and your problem-solving abilities.Proofread your resume carefully.

Before you submit your resume, proofread it carefully for any errors in grammar or spelling. A polished resume will make a good impression on potential employers.Tailor your resume to each job you apply for.

Take the time to tailor your resume to each job you apply for. This means highlighting the skills and experience that are most relevant to the specific position.

Essential Experience Highlights for a Strong Embossing Machine Operator Resume

- Utilized embossing machines to create raised designs on various materials including paper, fabric, and leather

- Skilled in operating both handfed and automatic embossing machines, ensuring efficient and precise production

- Established and maintained optimal machine settings to achieve desired embossing results, including pressure, temperature, and speed

- Inspected embossed products for quality, identifying and correcting any imperfections to meet customer specifications

- Performed regular machine maintenance and repairs to ensure optimal performance and prevent downtime

- Collaborated with production team to optimize production schedules and ensure timely delivery of embossed products

- Developed and implemented new embossing techniques to expand product offerings and meet changing market demands

- Trained and supervised new machine operators, providing guidance on safe and efficient embossing practices

Frequently Asked Questions (FAQ’s) For Embossing Machine Operator

What is an embossing machine operator?

An embossing machine operator is a skilled professional who uses embossing machines to create raised designs on a variety of materials, including paper, fabric, and leather. Embossing machines use pressure and heat to create a permanent impression in the material, resulting in a raised or textured design.

What are the responsibilities of an embossing machine operator?

The responsibilities of an embossing machine operator include setting up and operating embossing machines, maintaining optimal machine settings, inspecting embossed products for quality, and performing regular machine maintenance and repairs. Embossing machine operators may also be responsible for developing and implementing new embossing techniques, training new machine operators, and collaborating with production teams to optimize production schedules.

What are the qualifications for an embossing machine operator?

The qualifications for an embossing machine operator typically include a high school diploma or equivalent, as well as experience operating embossing machines. Some employers may prefer candidates with an associate’s degree in manufacturing technology or a related field.

What is the work environment of an embossing machine operator like?

Embossing machine operators typically work in manufacturing environments, such as factories or print shops. The work can be physically demanding, as it may involve lifting heavy materials and operating machinery. Embossing machine operators must also be able to work independently and as part of a team.

What is the career outlook for embossing machine operators?

The career outlook for embossing machine operators is expected to be good over the next few years. The demand for embossed products is expected to increase, as more businesses and consumers seek out unique and high-quality products.

What are the benefits of working as an embossing machine operator?

The benefits of working as an embossing machine operator include competitive pay, job security, and the opportunity to work with cutting-edge technology. Embossing machine operators also have the opportunity to learn new skills and develop their careers in the manufacturing industry.

What are the challenges of working as an embossing machine operator?

The challenges of working as an embossing machine operator include the physical demands of the job, the potential for repetitive motions, and the need to work in a fast-paced environment. Embossing machine operators must also be able to troubleshoot problems and work independently.

What is the average salary for an embossing machine operator?

The average salary for an embossing machine operator is $35,000 per year. However, salaries can vary depending on experience, location, and employer.