Are you a seasoned Engineering Model Maker seeking a new career path? Discover our professionally built Engineering Model Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

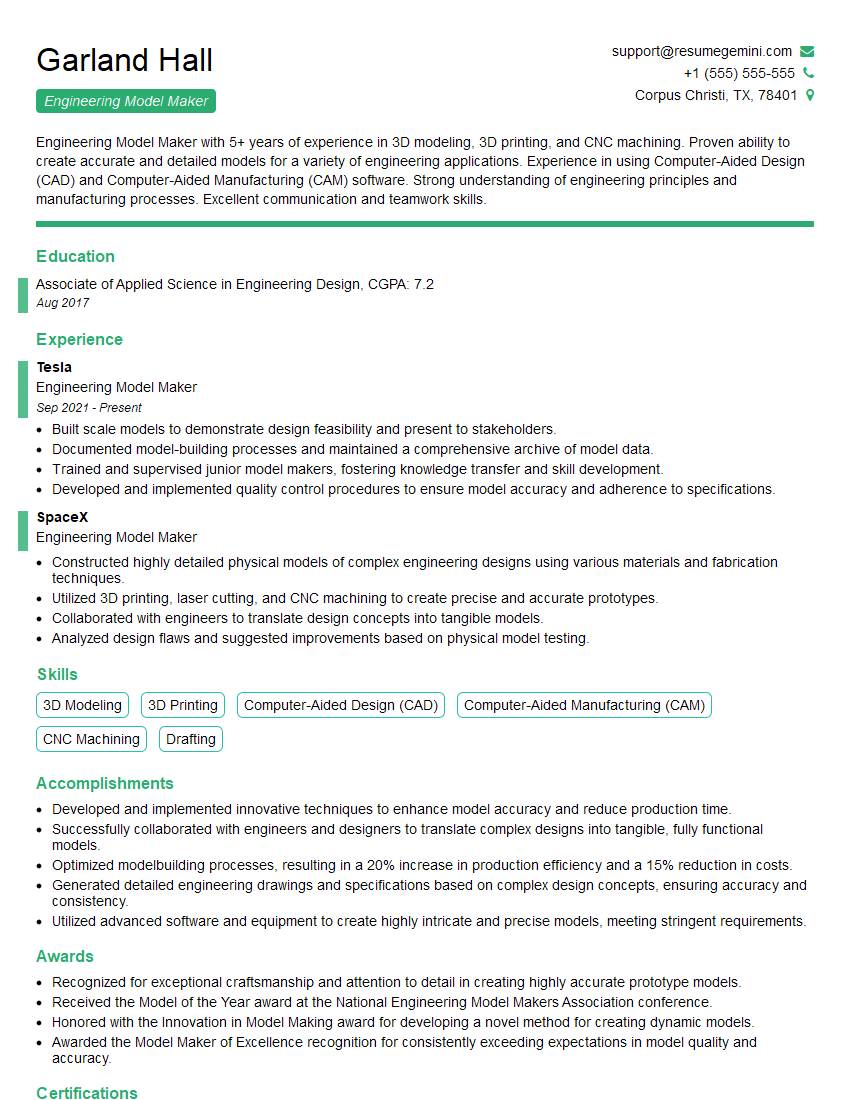

Garland Hall

Engineering Model Maker

Summary

Engineering Model Maker with 5+ years of experience in 3D modeling, 3D printing, and CNC machining. Proven ability to create accurate and detailed models for a variety of engineering applications. Experience in using Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software. Strong understanding of engineering principles and manufacturing processes. Excellent communication and teamwork skills.

Education

Associate of Applied Science in Engineering Design

August 2017

Skills

- 3D Modeling

- 3D Printing

- Computer-Aided Design (CAD)

- Computer-Aided Manufacturing (CAM)

- CNC Machining

- Drafting

Work Experience

Engineering Model Maker

- Built scale models to demonstrate design feasibility and present to stakeholders.

- Documented model-building processes and maintained a comprehensive archive of model data.

- Trained and supervised junior model makers, fostering knowledge transfer and skill development.

- Developed and implemented quality control procedures to ensure model accuracy and adherence to specifications.

Engineering Model Maker

- Constructed highly detailed physical models of complex engineering designs using various materials and fabrication techniques.

- Utilized 3D printing, laser cutting, and CNC machining to create precise and accurate prototypes.

- Collaborated with engineers to translate design concepts into tangible models.

- Analyzed design flaws and suggested improvements based on physical model testing.

Accomplishments

- Developed and implemented innovative techniques to enhance model accuracy and reduce production time.

- Successfully collaborated with engineers and designers to translate complex designs into tangible, fully functional models.

- Optimized modelbuilding processes, resulting in a 20% increase in production efficiency and a 15% reduction in costs.

- Generated detailed engineering drawings and specifications based on complex design concepts, ensuring accuracy and consistency.

- Utilized advanced software and equipment to create highly intricate and precise models, meeting stringent requirements.

Awards

- Recognized for exceptional craftsmanship and attention to detail in creating highly accurate prototype models.

- Received the Model of the Year award at the National Engineering Model Makers Association conference.

- Honored with the Innovation in Model Making award for developing a novel method for creating dynamic models.

- Awarded the Model Maker of Excellence recognition for consistently exceeding expectations in model quality and accuracy.

Certificates

- Certified Model Maker (CMM)

- Certified Mold Maker (CMM)

- Certified Pattern Maker (CPM)

- Certified Plastic Injection Mold Designer (CPIMD)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Engineering Model Maker

- Highlight your skills in 3D modeling, 3D printing, and CNC machining.

- Showcase your experience in using CAD and CAM software.

- Demonstrate your understanding of engineering principles and manufacturing processes.

- Provide examples of your work and how it has contributed to successful engineering projects.

Essential Experience Highlights for a Strong Engineering Model Maker Resume

- Create 3D models of parts and assemblies using CAD software

- Prepare 3D models for 3D printing and CNC machining

- Operate 3D printers and CNC machines to create physical models

- Inspect and measure physical models to ensure accuracy

- Document modeling and manufacturing processes

- Collaborate with engineers and designers to refine models and ensure they meet specifications

Frequently Asked Questions (FAQ’s) For Engineering Model Maker

What is the role of an Engineering Model Maker?

An Engineering Model Maker is responsible for creating physical models of parts and assemblies used in engineering and manufacturing. They use 3D modeling, 3D printing, and CNC machining to create accurate and detailed models that can be used for a variety of purposes, such as design verification, prototyping, and manufacturing planning.

What are the qualifications for becoming an Engineering Model Maker?

Most Engineering Model Makers have an associate degree in engineering design or a related field. They also have experience in using CAD and CAM software, as well as 3D printing and CNC machining equipment.

What are the career prospects for Engineering Model Makers?

Engineering Model Makers can find employment in a variety of industries, including automotive, aerospace, and manufacturing. They can also work in research and development, or as consultants.

What is the average salary for an Engineering Model Maker?

The average salary for an Engineering Model Maker is around $60,000 per year.

What are the benefits of working as an Engineering Model Maker?

Engineering Model Makers enjoy a number of benefits, including a good salary, job security, and the opportunity to work on challenging and rewarding projects.

What are the challenges of working as an Engineering Model Maker?

Engineering Model Makers face a number of challenges, including the need to stay up-to-date on the latest technology and the need to work with a variety of materials and processes.