Are you a seasoned Equipment Maintenance Supervisor seeking a new career path? Discover our professionally built Equipment Maintenance Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

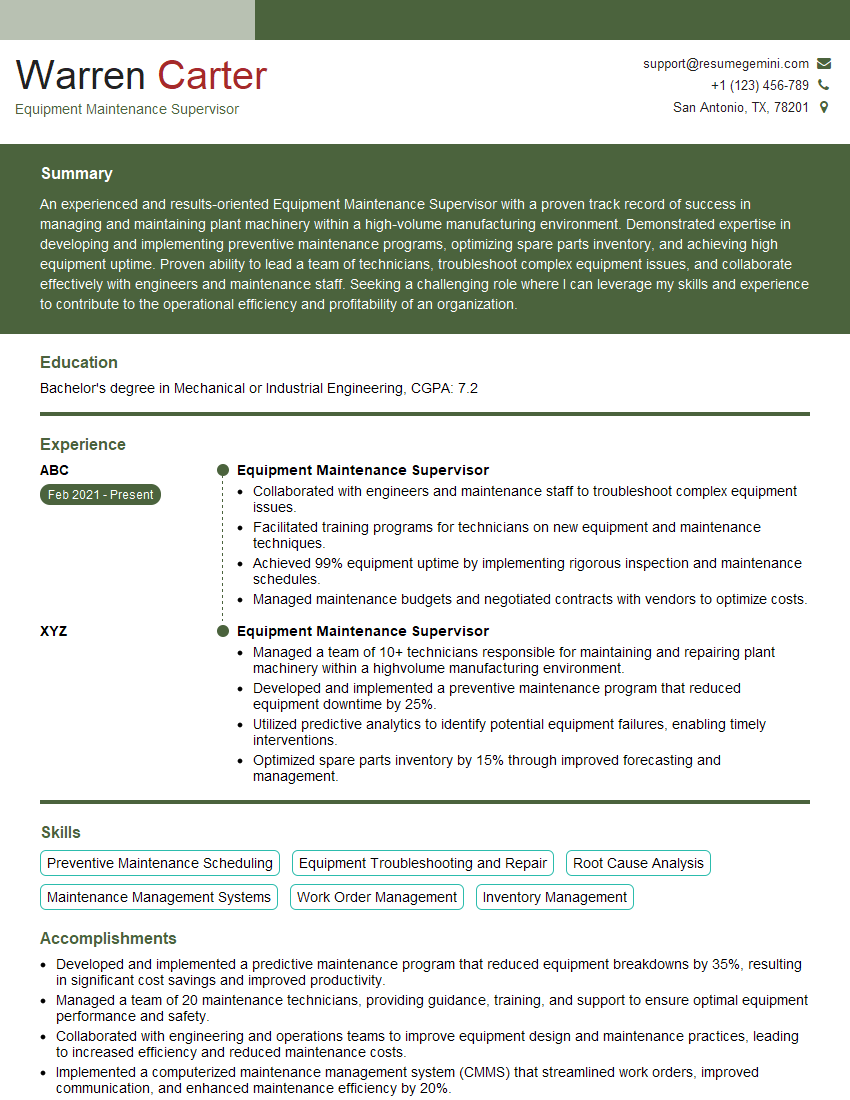

Warren Carter

Equipment Maintenance Supervisor

Summary

An experienced and results-oriented Equipment Maintenance Supervisor with a proven track record of success in managing and maintaining plant machinery within a high-volume manufacturing environment. Demonstrated expertise in developing and implementing preventive maintenance programs, optimizing spare parts inventory, and achieving high equipment uptime. Proven ability to lead a team of technicians, troubleshoot complex equipment issues, and collaborate effectively with engineers and maintenance staff. Seeking a challenging role where I can leverage my skills and experience to contribute to the operational efficiency and profitability of an organization.

Education

Bachelor’s degree in Mechanical or Industrial Engineering

January 2017

Skills

- Preventive Maintenance Scheduling

- Equipment Troubleshooting and Repair

- Root Cause Analysis

- Maintenance Management Systems

- Work Order Management

- Inventory Management

Work Experience

Equipment Maintenance Supervisor

- Collaborated with engineers and maintenance staff to troubleshoot complex equipment issues.

- Facilitated training programs for technicians on new equipment and maintenance techniques.

- Achieved 99% equipment uptime by implementing rigorous inspection and maintenance schedules.

- Managed maintenance budgets and negotiated contracts with vendors to optimize costs.

Equipment Maintenance Supervisor

- Managed a team of 10+ technicians responsible for maintaining and repairing plant machinery within a highvolume manufacturing environment.

- Developed and implemented a preventive maintenance program that reduced equipment downtime by 25%.

- Utilized predictive analytics to identify potential equipment failures, enabling timely interventions.

- Optimized spare parts inventory by 15% through improved forecasting and management.

Accomplishments

- Developed and implemented a predictive maintenance program that reduced equipment breakdowns by 35%, resulting in significant cost savings and improved productivity.

- Managed a team of 20 maintenance technicians, providing guidance, training, and support to ensure optimal equipment performance and safety.

- Collaborated with engineering and operations teams to improve equipment design and maintenance practices, leading to increased efficiency and reduced maintenance costs.

- Implemented a computerized maintenance management system (CMMS) that streamlined work orders, improved communication, and enhanced maintenance efficiency by 20%.

- Developed a training program for maintenance technicians that increased their skills and knowledge, resulting in improved equipment uptime and reduced maintenance costs.

Awards

- Recipient of the Excellence in Equipment Maintenance award for outstanding performance in maintaining critical equipment with minimal downtime.

- Recognized by the Maintenance Excellence Network for exceptional leadership and innovation in equipment maintenance strategies.

- Received the Supervisor of the Year award for consistently exceeding performance expectations and fostering a positive work environment.

- Recognized by the National Maintenance Association for contributions to industry best practices and technical advancements in equipment maintenance.

Certificates

- Certified Maintenance and Reliability Professional (CMRP)

- Society for Maintenance & Reliability Professionals (SMRP)

- Certified Preventive Maintenance Manager (CPMM)

- Certified Maintenance & Reliability Engineer (CMRE)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Equipment Maintenance Supervisor

- Highlight your technical expertise: Emphasize your skills in preventive maintenance scheduling, equipment troubleshooting, root cause analysis, and maintenance management systems.

- Quantify your accomplishments: Provide specific data and metrics to demonstrate the impact of your work, such as reduced downtime, increased uptime, and improved equipment performance.

- Showcase your leadership abilities: Describe your experience in leading and motivating a team of technicians, including your ability to delegate tasks, resolve conflicts, and provide constructive feedback.

- Demonstrate your commitment to continuous improvement: Highlight your efforts to stay abreast of industry best practices and your willingness to implement new technologies and strategies to enhance maintenance operations.

Essential Experience Highlights for a Strong Equipment Maintenance Supervisor Resume

- Supervise and lead a team of technicians responsible for maintaining and repairing plant machinery.

- Develop and implement preventive maintenance programs to reduce equipment downtime and improve overall equipment effectiveness.

- Utilize predictive analytics to identify potential equipment failures and take proactive measures to prevent them.

- Optimize spare parts inventory by analyzing usage data and implementing demand forecasting techniques.

- Collaborate with engineers and maintenance staff to troubleshoot complex equipment issues and develop solutions to ensure optimal performance.

- Facilitate training programs for technicians on new equipment and maintenance techniques to enhance their skills and knowledge.

- Monitor equipment performance, conduct regular inspections, and maintain accurate maintenance records to ensure compliance with industry standards.

Frequently Asked Questions (FAQ’s) For Equipment Maintenance Supervisor

What are the key skills required to be a successful Equipment Maintenance Supervisor?

Key skills include preventive maintenance scheduling, equipment troubleshooting and repair, root cause analysis, maintenance management systems, work order management, inventory management, and leadership abilities.

What is the career outlook for Equipment Maintenance Supervisors?

The job outlook for Equipment Maintenance Supervisors is expected to grow faster than average, driven by the increasing demand for skilled professionals to maintain and repair complex machinery and equipment.

What are the typical salary ranges for Equipment Maintenance Supervisors?

The salary ranges for Equipment Maintenance Supervisors vary depending on experience, location, and industry, but generally fall within the range of $50,000 to $100,000 per year.

What are the common career paths for Equipment Maintenance Supervisors?

Common career paths include Maintenance Manager, Plant Manager, and Operations Manager.

What are the challenges faced by Equipment Maintenance Supervisors?

Challenges include managing a team of technicians, ensuring equipment uptime, troubleshooting complex issues, and staying abreast of new technologies and industry best practices.

What advice would you give to someone aspiring to become an Equipment Maintenance Supervisor?

Gain hands-on experience in equipment maintenance, pursue a relevant degree or certification, develop strong technical and leadership skills, and stay informed about industry trends and advancements.

What are the top qualities of a successful Equipment Maintenance Supervisor?

Successful Equipment Maintenance Supervisors are typically highly organized, detail-oriented, analytical, proactive, and possess excellent communication and interpersonal skills.