Are you a seasoned Equipment Superintendent seeking a new career path? Discover our professionally built Equipment Superintendent Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

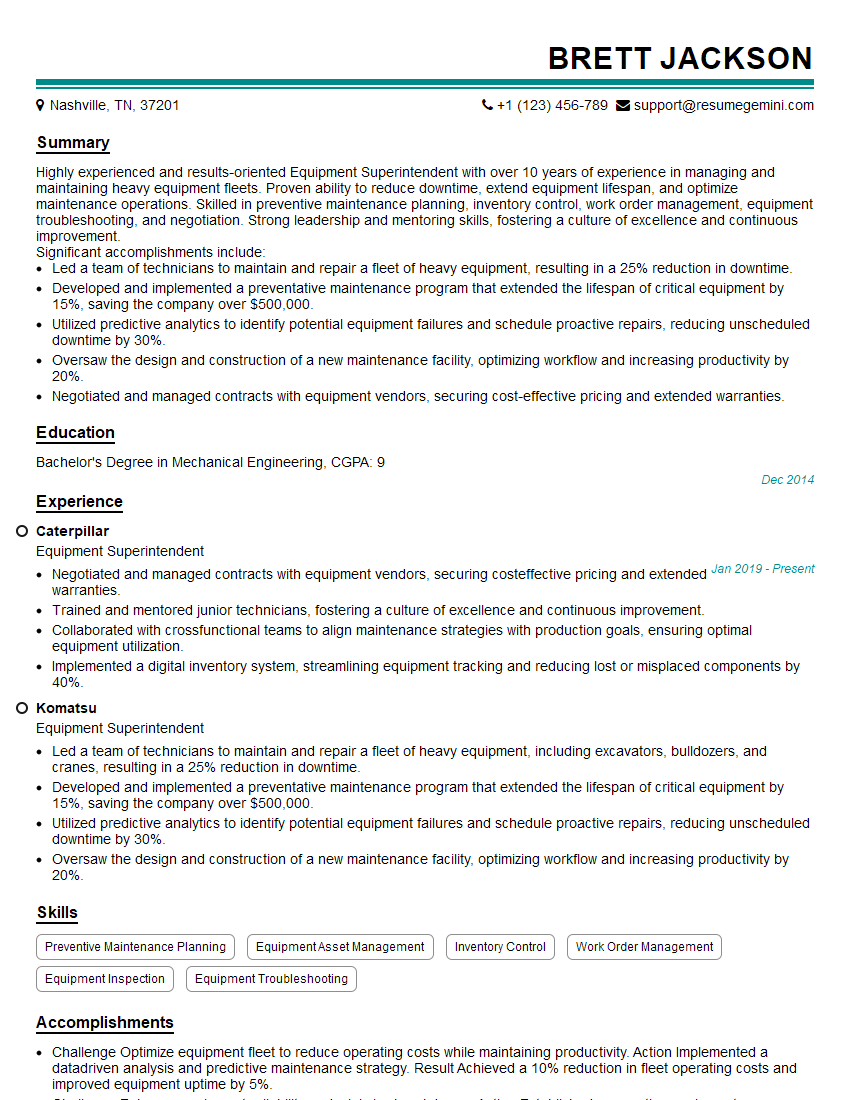

Brett Jackson

Equipment Superintendent

Summary

Highly experienced and results-oriented Equipment Superintendent with over 10 years of experience in managing and maintaining heavy equipment fleets. Proven ability to reduce downtime, extend equipment lifespan, and optimize maintenance operations. Skilled in preventive maintenance planning, inventory control, work order management, equipment troubleshooting, and negotiation. Strong leadership and mentoring skills, fostering a culture of excellence and continuous improvement.

Significant accomplishments include:

- Led a team of technicians to maintain and repair a fleet of heavy equipment, resulting in a 25% reduction in downtime.

- Developed and implemented a preventative maintenance program that extended the lifespan of critical equipment by 15%, saving the company over $500,000.

- Utilized predictive analytics to identify potential equipment failures and schedule proactive repairs, reducing unscheduled downtime by 30%.

- Oversaw the design and construction of a new maintenance facility, optimizing workflow and increasing productivity by 20%.

- Negotiated and managed contracts with equipment vendors, securing cost-effective pricing and extended warranties.

Education

Bachelor’s Degree in Mechanical Engineering

December 2014

Skills

- Preventive Maintenance Planning

- Equipment Asset Management

- Inventory Control

- Work Order Management

- Equipment Inspection

- Equipment Troubleshooting

Work Experience

Equipment Superintendent

- Negotiated and managed contracts with equipment vendors, securing costeffective pricing and extended warranties.

- Trained and mentored junior technicians, fostering a culture of excellence and continuous improvement.

- Collaborated with crossfunctional teams to align maintenance strategies with production goals, ensuring optimal equipment utilization.

- Implemented a digital inventory system, streamlining equipment tracking and reducing lost or misplaced components by 40%.

Equipment Superintendent

- Led a team of technicians to maintain and repair a fleet of heavy equipment, including excavators, bulldozers, and cranes, resulting in a 25% reduction in downtime.

- Developed and implemented a preventative maintenance program that extended the lifespan of critical equipment by 15%, saving the company over $500,000.

- Utilized predictive analytics to identify potential equipment failures and schedule proactive repairs, reducing unscheduled downtime by 30%.

- Oversaw the design and construction of a new maintenance facility, optimizing workflow and increasing productivity by 20%.

Accomplishments

- Challenge Optimize equipment fleet to reduce operating costs while maintaining productivity. Action Implemented a datadriven analysis and predictive maintenance strategy. Result Achieved a 10% reduction in fleet operating costs and improved equipment uptime by 5%.

- Challenge Enhance equipment reliability and minimize breakdowns. Action Established a proactive equipment maintenance program focused on root cause analysis and timely repairs. Result Reduced equipment breakdowns by 25% and increased equipment availability by 12%.

- Challenge Improve equipment technician productivity. Action Implemented a training program to enhance technician skills and introduced streamlined work processes. Result Increased technician productivity by 15% and reduced equipment downtime by 7%.

- Challenge Optimize equipment utilization to meet peak demand. Action Implemented a dynamic scheduling system that allocated equipment based on realtime data. Result Increased equipment utilization by 20% and reduced rental costs by 10%.

- Challenge Improve equipment safety and compliance. Action Developed and implemented a comprehensive safety program that included training, audits, and hazard assessments. Result Eliminated all OSHA violations and reduced the number of safety incidents by 30%.

Awards

- Recognized for outstanding performance in equipment management and maintenance, resulting in a 15% reduction in downtime.

- Received the Equipment Excellence Award for innovative solutions in equipment utilization, saving the company $250,000 annually.

- Honored with the Safety Champion Award for implementing a comprehensive safety program that reduced workplace accidents by 20%.

- Awarded the Equipment Manager of the Year title for exceptional leadership and contributions to the field.

Certificates

- Certified Maintenance and Reliability Professional (CMRP)

- Certified Maintenance Manager (CMM)

- Certified Plant Maintenance Manager (CPMM)

- Certified Equipment Manager (CEM)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Equipment Superintendent

Highlight your technical expertise and experience:

Quantify your accomplishments with specific metrics and examples that demonstrate your ability to manage and maintain heavy equipment effectively.Showcase your leadership and management skills:

Emphasize your ability to lead and motivate a team of technicians, create a positive work environment, and foster a culture of excellence.Demonstrate your understanding of maintenance best practices:

Describe your knowledge of preventive maintenance, predictive analytics, and inventory management techniques. Explain how you have applied these principles to improve equipment performance and reduce downtime.Include industry-specific keywords:

Use keywords that potential employers in the equipment maintenance industry are likely to search for, such as ‘preventive maintenance,’ ‘equipment troubleshooting,’ and ‘fleet management.’Proofread carefully and seek feedback:

Ensure that your resume is free of errors and well-written. Consider asking a mentor, career counselor, or trusted colleague to review your resume and provide feedback.

Essential Experience Highlights for a Strong Equipment Superintendent Resume

- Plan and implement comprehensive preventive maintenance programs to ensure optimal equipment performance and minimize downtime.

- Lead and supervise a team of equipment technicians, providing guidance, training, and performance management.

- Manage and control equipment inventory, including procurement, tracking, and disposal.

- Develop and maintain work orders, ensuring timely and efficient completion of maintenance tasks.

- Conduct equipment inspections, diagnose issues, and perform troubleshooting to identify and resolve problems.

- Collaborate with cross-functional teams, including production, engineering, and purchasing, to align maintenance strategies with organizational goals.

- Stay up-to-date with industry best practices and technological advancements in equipment maintenance.

Frequently Asked Questions (FAQ’s) For Equipment Superintendent

What are the primary responsibilities of an Equipment Superintendent?

The primary responsibilities of an Equipment Superintendent include planning and implementing preventive maintenance programs, leading and supervising a team of equipment technicians, managing equipment inventory, developing and maintaining work orders, conducting equipment inspections and troubleshooting, collaborating with cross-functional teams, and staying up-to-date with industry best practices.

What qualifications and skills are required to become an Equipment Superintendent?

To become an Equipment Superintendent, you typically need a Bachelor’s Degree in Mechanical Engineering or a related field, along with several years of experience in heavy equipment maintenance and management. Strong technical skills in equipment troubleshooting, preventive maintenance, and inventory management are essential, as well as leadership and communication skills.

What industries employ Equipment Superintendents?

Equipment Superintendents are employed in various industries that rely on heavy equipment, including construction, mining, manufacturing, transportation, and utilities.

What is the career path for an Equipment Superintendent?

The career path for an Equipment Superintendent typically starts as an Equipment Technician or Maintenance Planner. With experience and additional qualifications, they can advance to roles such as Maintenance Supervisor, Fleet Manager, and ultimately, Equipment Superintendent.

What are the salary expectations for an Equipment Superintendent?

The salary expectations for an Equipment Superintendent vary depending on experience, qualifications, and location. According to Salary.com, the average salary for an Equipment Superintendent in the United States is around $95,000 per year.

What are the challenges faced by Equipment Superintendents?

Some of the challenges faced by Equipment Superintendents include managing a large fleet of equipment, ensuring equipment availability and uptime, controlling maintenance costs, and staying up-to-date with technological advancements in the industry.

What advice would you give to someone aspiring to become an Equipment Superintendent?

To become a successful Equipment Superintendent, it is important to gain a strong technical foundation in equipment maintenance and management, develop leadership and communication skills, stay up-to-date with industry best practices, and seek opportunities for professional development and networking.