Are you a seasoned Ethanol Maintenance Mechanic seeking a new career path? Discover our professionally built Ethanol Maintenance Mechanic Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

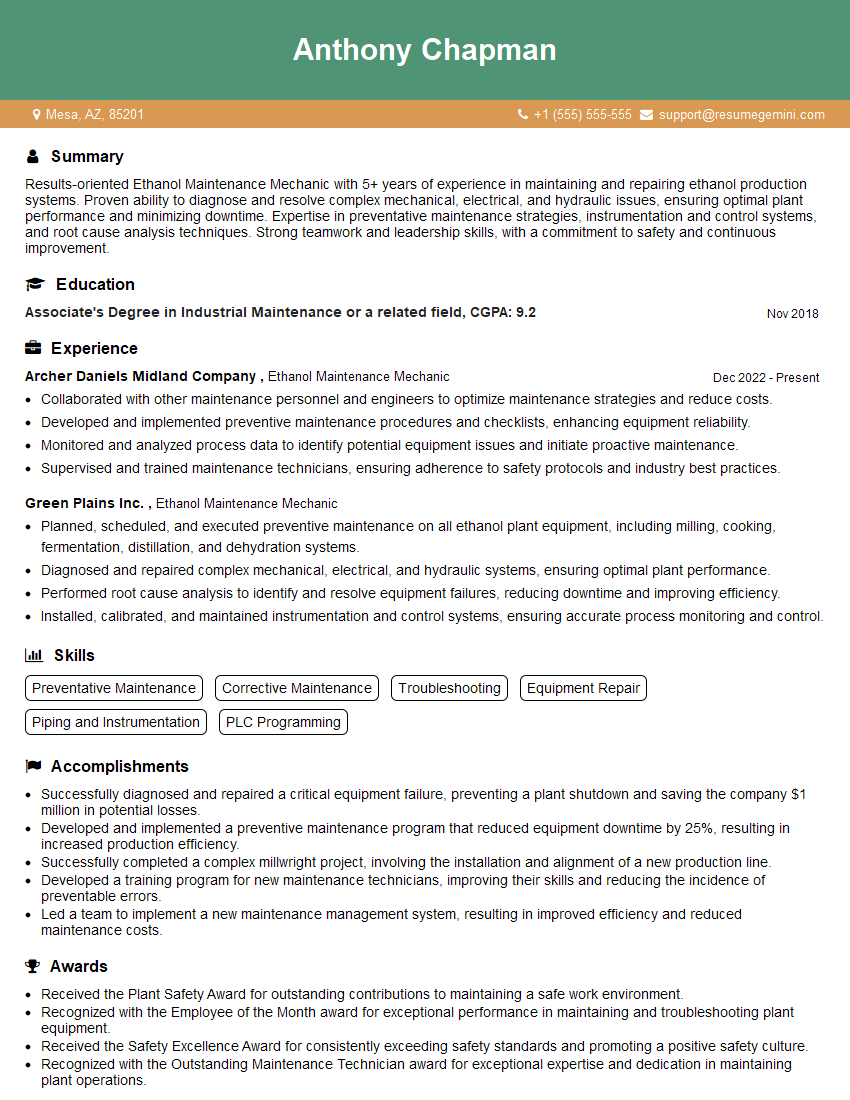

Anthony Chapman

Ethanol Maintenance Mechanic

Summary

Results-oriented Ethanol Maintenance Mechanic with 5+ years of experience in maintaining and repairing ethanol production systems. Proven ability to diagnose and resolve complex mechanical, electrical, and hydraulic issues, ensuring optimal plant performance and minimizing downtime. Expertise in preventative maintenance strategies, instrumentation and control systems, and root cause analysis techniques. Strong teamwork and leadership skills, with a commitment to safety and continuous improvement.

Education

Associate’s Degree in Industrial Maintenance or a related field

November 2018

Skills

- Preventative Maintenance

- Corrective Maintenance

- Troubleshooting

- Equipment Repair

- Piping and Instrumentation

- PLC Programming

Work Experience

Ethanol Maintenance Mechanic

- Collaborated with other maintenance personnel and engineers to optimize maintenance strategies and reduce costs.

- Developed and implemented preventive maintenance procedures and checklists, enhancing equipment reliability.

- Monitored and analyzed process data to identify potential equipment issues and initiate proactive maintenance.

- Supervised and trained maintenance technicians, ensuring adherence to safety protocols and industry best practices.

Ethanol Maintenance Mechanic

- Planned, scheduled, and executed preventive maintenance on all ethanol plant equipment, including milling, cooking, fermentation, distillation, and dehydration systems.

- Diagnosed and repaired complex mechanical, electrical, and hydraulic systems, ensuring optimal plant performance.

- Performed root cause analysis to identify and resolve equipment failures, reducing downtime and improving efficiency.

- Installed, calibrated, and maintained instrumentation and control systems, ensuring accurate process monitoring and control.

Accomplishments

- Successfully diagnosed and repaired a critical equipment failure, preventing a plant shutdown and saving the company $1 million in potential losses.

- Developed and implemented a preventive maintenance program that reduced equipment downtime by 25%, resulting in increased production efficiency.

- Successfully completed a complex millwright project, involving the installation and alignment of a new production line.

- Developed a training program for new maintenance technicians, improving their skills and reducing the incidence of preventable errors.

- Led a team to implement a new maintenance management system, resulting in improved efficiency and reduced maintenance costs.

Awards

- Received the Plant Safety Award for outstanding contributions to maintaining a safe work environment.

- Recognized with the Employee of the Month award for exceptional performance in maintaining and troubleshooting plant equipment.

- Received the Safety Excellence Award for consistently exceeding safety standards and promoting a positive safety culture.

- Recognized with the Outstanding Maintenance Technician award for exceptional expertise and dedication in maintaining plant operations.

Certificates

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Maintenance Manager (CMM)

- Certified Plant Maintenance Manager (CPMM)

- ISA Certified Automation Professional (CAP)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Ethanol Maintenance Mechanic

- Highlight your experience in ethanol production systems, specifically with milling, cooking, fermentation, distillation, and dehydration equipment.

- Quantify your accomplishments with specific metrics, such as reducing downtime or improving efficiency.

- Demonstrate your expertise in troubleshooting and repairing complex mechanical, electrical, and hydraulic systems.

- Emphasize your knowledge of instrumentation and control systems, including installation, calibration, and maintenance.

- Showcase your leadership and teamwork skills, as well as your commitment to safety and continuous improvement.

Essential Experience Highlights for a Strong Ethanol Maintenance Mechanic Resume

- Planned, scheduled, and executed preventive maintenance on all ethanol plant equipment, including milling, cooking, fermentation, distillation, and dehydration systems.

- Diagnosed and repaired complex mechanical, electrical, and hydraulic systems, ensuring optimal plant performance.

- Performed root cause analysis to identify and resolve equipment failures, reducing downtime and improving efficiency.

- Installed, calibrated, and maintained instrumentation and control systems, ensuring accurate process monitoring and control.

- Collaborated with other maintenance personnel and engineers to optimize maintenance strategies and reduce costs.

- Developed and implemented preventive maintenance procedures and checklists, enhancing equipment reliability.

- Monitored and analyzed process data to identify potential equipment issues and initiate proactive maintenance.

- Supervised and trained maintenance technicians, ensuring adherence to safety protocols and industry best practices.

Frequently Asked Questions (FAQ’s) For Ethanol Maintenance Mechanic

What are the primary responsibilities of an Ethanol Maintenance Mechanic?

Ethanol Maintenance Mechanics are responsible for maintaining and repairing ethanol production systems, including diagnosing and resolving mechanical, electrical, and hydraulic issues, performing preventive maintenance, and implementing maintenance strategies to ensure optimal plant performance and minimize downtime.

What qualifications are typically required for an Ethanol Maintenance Mechanic?

Typically, an Associate’s Degree in Industrial Maintenance or a related field is required, along with experience in maintaining and repairing ethanol production systems or similar industrial equipment.

What are the key skills and abilities needed to be an effective Ethanol Maintenance Mechanic?

Effective Ethanol Maintenance Mechanics possess strong mechanical, electrical, and hydraulic troubleshooting and repair skills, knowledge of instrumentation and control systems, and experience in implementing preventive maintenance strategies. They are also typically proficient in root cause analysis techniques and have a commitment to safety and continuous improvement.

What are the career advancement opportunities for an Ethanol Maintenance Mechanic?

With experience and additional training, Ethanol Maintenance Mechanics can advance to roles such as Maintenance Supervisor, Maintenance Manager, or Plant Engineer, or they may specialize in a particular area of maintenance, such as electrical or instrumentation maintenance.

What is the job outlook for Ethanol Maintenance Mechanics?

The job outlook for Ethanol Maintenance Mechanics is expected to be favorable as the demand for ethanol production continues to grow due to its use as a renewable fuel source.

How can I prepare for a career as an Ethanol Maintenance Mechanic?

To prepare for a career as an Ethanol Maintenance Mechanic, you can pursue an education in Industrial Maintenance or a related field, gain hands-on experience through internships or apprenticeships, and obtain certifications in relevant areas such as electrical or instrumentation maintenance.

What are some of the challenges faced by Ethanol Maintenance Mechanics?

Ethanol Maintenance Mechanics may face challenges such as working in a fast-paced and demanding environment, dealing with hazardous or flammable materials, and being on-call for emergencies.