Are you a seasoned Explosion Welder seeking a new career path? Discover our professionally built Explosion Welder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

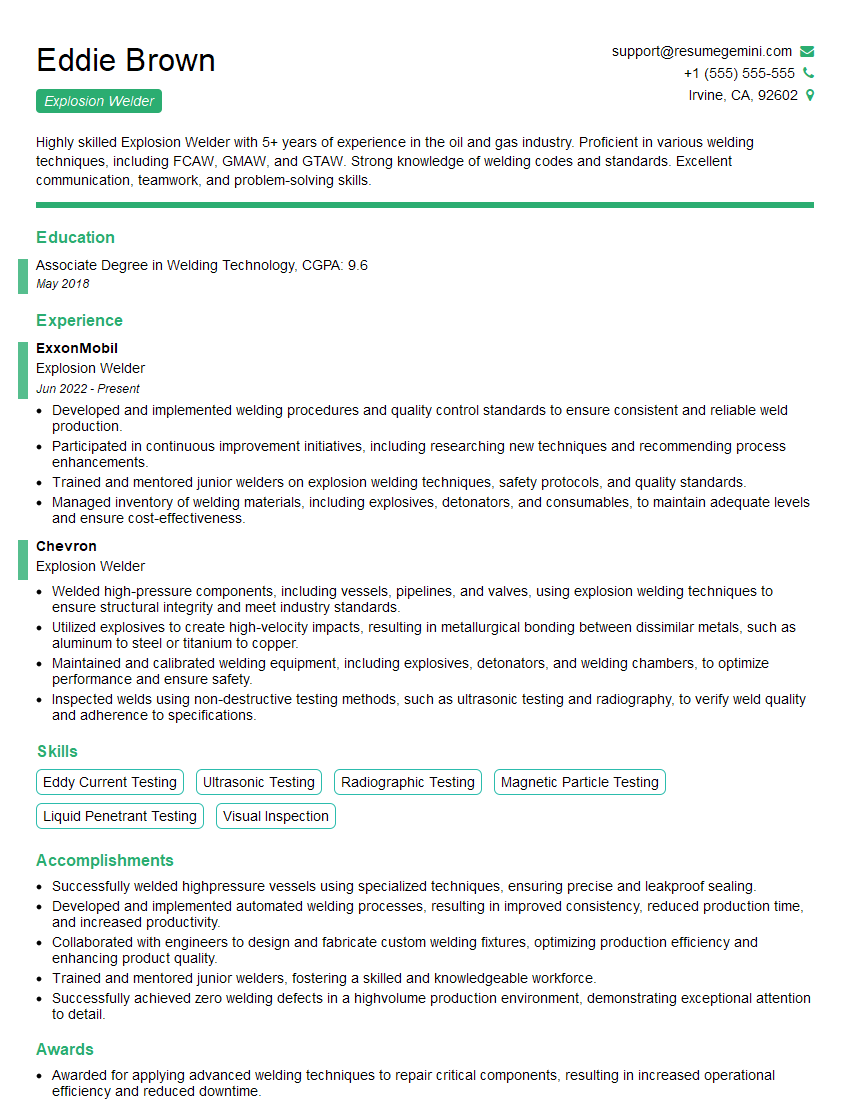

Eddie Brown

Explosion Welder

Summary

Highly skilled Explosion Welder with 5+ years of experience in the oil and gas industry. Proficient in various welding techniques, including FCAW, GMAW, and GTAW. Strong knowledge of welding codes and standards. Excellent communication, teamwork, and problem-solving skills.

Education

Associate Degree in Welding Technology

May 2018

Skills

- Eddy Current Testing

- Ultrasonic Testing

- Radiographic Testing

- Magnetic Particle Testing

- Liquid Penetrant Testing

- Visual Inspection

Work Experience

Explosion Welder

- Developed and implemented welding procedures and quality control standards to ensure consistent and reliable weld production.

- Participated in continuous improvement initiatives, including researching new techniques and recommending process enhancements.

- Trained and mentored junior welders on explosion welding techniques, safety protocols, and quality standards.

- Managed inventory of welding materials, including explosives, detonators, and consumables, to maintain adequate levels and ensure cost-effectiveness.

Explosion Welder

- Welded high-pressure components, including vessels, pipelines, and valves, using explosion welding techniques to ensure structural integrity and meet industry standards.

- Utilized explosives to create high-velocity impacts, resulting in metallurgical bonding between dissimilar metals, such as aluminum to steel or titanium to copper.

- Maintained and calibrated welding equipment, including explosives, detonators, and welding chambers, to optimize performance and ensure safety.

- Inspected welds using non-destructive testing methods, such as ultrasonic testing and radiography, to verify weld quality and adherence to specifications.

Accomplishments

- Successfully welded highpressure vessels using specialized techniques, ensuring precise and leakproof sealing.

- Developed and implemented automated welding processes, resulting in improved consistency, reduced production time, and increased productivity.

- Collaborated with engineers to design and fabricate custom welding fixtures, optimizing production efficiency and enhancing product quality.

- Trained and mentored junior welders, fostering a skilled and knowledgeable workforce.

- Successfully achieved zero welding defects in a highvolume production environment, demonstrating exceptional attention to detail.

Awards

- Awarded for applying advanced welding techniques to repair critical components, resulting in increased operational efficiency and reduced downtime.

- Recognized for consistently exceeding production targets while maintaining exceptional quality standards, contributing to team success.

- Received an industrywide award for developing a novel solution to a complex welding challenge, enhancing safety protocols.

- Certified by the American Welding Society (AWS) as a Certified Welding Inspector (CWI), meeting industry standards and ensuring weld quality.

Certificates

- AWS Certified Welding Inspector (CWI)

- ASNT Level II Non-Destructive Testing Technician Certification

- ASME Boiler and Pressure Vessel Code Authorization

- OSHA Safety 10-Hour Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Explosion Welder

- Highlight your welding certifications and experience.

- Showcase your knowledge of welding codes and standards.

- Emphasize your experience in the oil and gas industry.

- Use keywords that potential employers will be searching for.

Essential Experience Highlights for a Strong Explosion Welder Resume

- Prepare and assemble welding equipment and materials.

- Set up and operate explosion welding machines.

- Monitor and control welding parameters to ensure quality and safety.

- Inspect and test welded joints using Eddy Current Testing, Ultrasonic Testing, Radiographic Testing, Magnetic Particle Testing, Liquid Penetrant Testing, and Visual Inspection.

- Maintain a clean and organized work area.

- Adhere to all safety regulations and procedures.

Frequently Asked Questions (FAQ’s) For Explosion Welder

What is explosion welding?

Explosion welding is a solid-state welding process that uses the force of an explosion to join two metal surfaces. The process is typically used to join dissimilar metals that cannot be welded using traditional methods.

What are the advantages of explosion welding?

Explosion welding offers several advantages over traditional welding methods, including the ability to join dissimilar metals, the production of high-strength welds, and the ability to weld large areas quickly.

What are the disadvantages of explosion welding?

Explosion welding also has some disadvantages, including the need for specialized equipment, the potential for noise and vibration, and the production of hazardous fumes.

What are the applications of explosion welding?

Explosion welding is used in a variety of applications, including the manufacture of aircraft, spacecraft, and automotive components, as well as in the construction of pipelines and pressure vessels.

What are the safety precautions that must be taken when explosion welding?

When explosion welding, it is important to take several safety precautions, including wearing proper protective clothing, using earplugs or ear muffs to protect against noise, and ensuring that the work area is well-ventilated.