Are you a seasoned Extruding Machine Operator/Setter/Tender seeking a new career path? Discover our professionally built Extruding Machine Operator/Setter/Tender Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

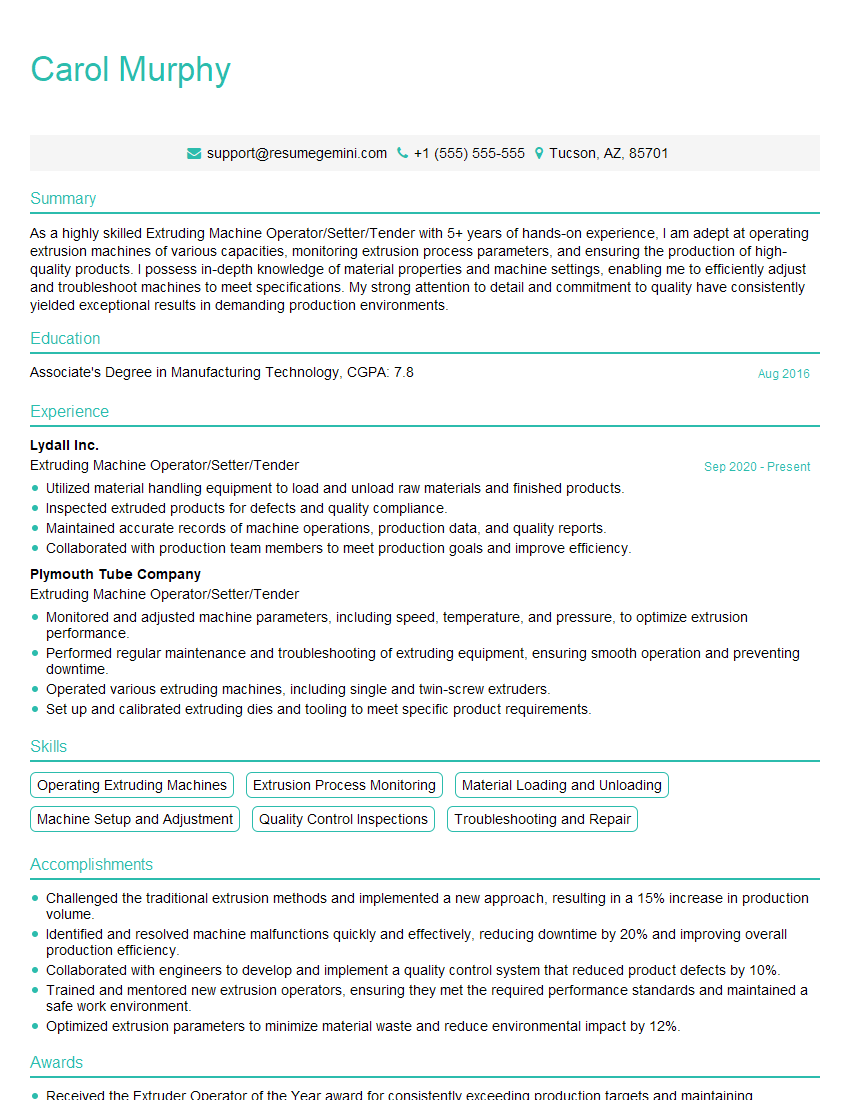

Carol Murphy

Extruding Machine Operator/Setter/Tender

Summary

As a highly skilled Extruding Machine Operator/Setter/Tender with 5+ years of hands-on experience, I am adept at operating extrusion machines of various capacities, monitoring extrusion process parameters, and ensuring the production of high-quality products. I possess in-depth knowledge of material properties and machine settings, enabling me to efficiently adjust and troubleshoot machines to meet specifications. My strong attention to detail and commitment to quality have consistently yielded exceptional results in demanding production environments.

Education

Associate’s Degree in Manufacturing Technology

August 2016

Skills

- Operating Extruding Machines

- Extrusion Process Monitoring

- Material Loading and Unloading

- Machine Setup and Adjustment

- Quality Control Inspections

- Troubleshooting and Repair

Work Experience

Extruding Machine Operator/Setter/Tender

- Utilized material handling equipment to load and unload raw materials and finished products.

- Inspected extruded products for defects and quality compliance.

- Maintained accurate records of machine operations, production data, and quality reports.

- Collaborated with production team members to meet production goals and improve efficiency.

Extruding Machine Operator/Setter/Tender

- Monitored and adjusted machine parameters, including speed, temperature, and pressure, to optimize extrusion performance.

- Performed regular maintenance and troubleshooting of extruding equipment, ensuring smooth operation and preventing downtime.

- Operated various extruding machines, including single and twin-screw extruders.

- Set up and calibrated extruding dies and tooling to meet specific product requirements.

Accomplishments

- Challenged the traditional extrusion methods and implemented a new approach, resulting in a 15% increase in production volume.

- Identified and resolved machine malfunctions quickly and effectively, reducing downtime by 20% and improving overall production efficiency.

- Collaborated with engineers to develop and implement a quality control system that reduced product defects by 10%.

- Trained and mentored new extrusion operators, ensuring they met the required performance standards and maintained a safe work environment.

- Optimized extrusion parameters to minimize material waste and reduce environmental impact by 12%.

Awards

- Received the Extruder Operator of the Year award for consistently exceeding production targets and maintaining exceptional machine efficiency.

- Recognized with the Safety Excellence Award for implementing innovative safety measures that significantly reduced workplace accidents.

- Awarded the Employee of the Month honor multiple times for outstanding performance and dedication to the extrusion process.

Certificates

- Certified Extrusion Operator (CEO)

- OSHA Safety Certification

- ISO 9001 Quality Management Certification

- Lean Manufacturing Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Extruding Machine Operator/Setter/Tender

- Quantify your accomplishments using specific metrics and data whenever possible.

- Highlight your ability to troubleshoot and resolve complex technical issues.

- Emphasize your understanding of extrusion principles and the impact of process parameters on product quality.

- Include relevant industry certifications or training programs to demonstrate your commitment to professional development.

Essential Experience Highlights for a Strong Extruding Machine Operator/Setter/Tender Resume

- Set up and adjust extrusion machines, ensuring optimal operating conditions based on material properties and product specifications.

- Monitor extrusion process parameters such as temperature, pressure, and flow rate to maintain process stability and product quality.

- Load and unload raw materials and finished products safely and efficiently using forklifts or other material handling equipment.

- Inspect products regularly to verify dimensions, surface finish, and overall quality against established standards.

- Identify and resolve machine malfunctions, perform routine maintenance, and make necessary repairs to ensure smooth production.

- Collaborate with supervisors, engineers, and quality control personnel to optimize machine performance and troubleshoot complex issues.

- Maintain a clean and organized work area, adhering to safety regulations and industry best practices.

Frequently Asked Questions (FAQ’s) For Extruding Machine Operator/Setter/Tender

What are the key skills required for an Extruding Machine Operator/Setter/Tender?

Key skills include operating extrusion machines, monitoring extrusion processes, loading and unloading materials, troubleshooting and repairs, and quality control inspections.

What industries employ Extruding Machine Operators/Setters/Tenders?

Extruding Machine Operators/Setters/Tenders are employed in various industries, including manufacturing, construction, and plastics.

What is the career outlook for Extruding Machine Operators/Setters/Tenders?

The career outlook is expected to be good, with an increasing demand for skilled operators due to advancements in extrusion technology.

What are the potential salary ranges for Extruding Machine Operators/Setters/Tenders?

Salary ranges vary depending on experience, location, and industry, but typically range from around $15 to $25 per hour.

Are there opportunities for advancement for Extruding Machine Operators/Setters/Tenders?

Yes, there are potential advancement opportunities to roles such as extrusion technician, production supervisor, or quality control inspector.

What type of training is required to become an Extruding Machine Operator/Setter/Tender?

Training can include on-the-job training, vocational programs, or community college courses in manufacturing technology.

What is the work environment like for Extruding Machine Operators/Setters/Tenders?

Work environments can vary but typically involve working in production areas with moderate noise levels and potential exposure to chemicals or molten materials.

What safety precautions should Extruding Machine Operators/Setters/Tenders observe?

Safety precautions include wearing appropriate protective gear, following lockout/tagout procedures, and adhering to established safety protocols.