Are you a seasoned Extrusion Die Repairer seeking a new career path? Discover our professionally built Extrusion Die Repairer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

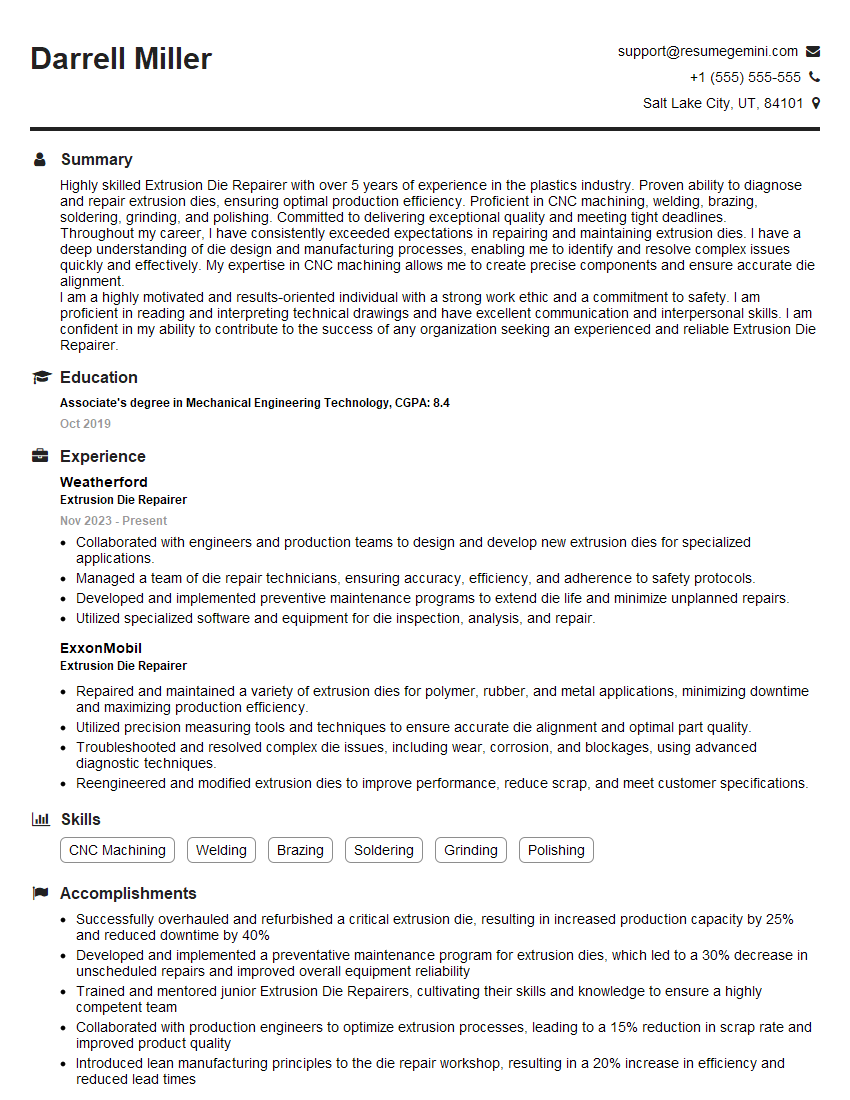

Darrell Miller

Extrusion Die Repairer

Summary

Highly skilled Extrusion Die Repairer with over 5 years of experience in the plastics industry. Proven ability to diagnose and repair extrusion dies, ensuring optimal production efficiency. Proficient in CNC machining, welding, brazing, soldering, grinding, and polishing. Committed to delivering exceptional quality and meeting tight deadlines.

Throughout my career, I have consistently exceeded expectations in repairing and maintaining extrusion dies. I have a deep understanding of die design and manufacturing processes, enabling me to identify and resolve complex issues quickly and effectively. My expertise in CNC machining allows me to create precise components and ensure accurate die alignment.

I am a highly motivated and results-oriented individual with a strong work ethic and a commitment to safety. I am proficient in reading and interpreting technical drawings and have excellent communication and interpersonal skills. I am confident in my ability to contribute to the success of any organization seeking an experienced and reliable Extrusion Die Repairer.

Education

Associate’s degree in Mechanical Engineering Technology

October 2019

Skills

- CNC Machining

- Welding

- Brazing

- Soldering

- Grinding

- Polishing

Work Experience

Extrusion Die Repairer

- Collaborated with engineers and production teams to design and develop new extrusion dies for specialized applications.

- Managed a team of die repair technicians, ensuring accuracy, efficiency, and adherence to safety protocols.

- Developed and implemented preventive maintenance programs to extend die life and minimize unplanned repairs.

- Utilized specialized software and equipment for die inspection, analysis, and repair.

Extrusion Die Repairer

- Repaired and maintained a variety of extrusion dies for polymer, rubber, and metal applications, minimizing downtime and maximizing production efficiency.

- Utilized precision measuring tools and techniques to ensure accurate die alignment and optimal part quality.

- Troubleshooted and resolved complex die issues, including wear, corrosion, and blockages, using advanced diagnostic techniques.

- Reengineered and modified extrusion dies to improve performance, reduce scrap, and meet customer specifications.

Accomplishments

- Successfully overhauled and refurbished a critical extrusion die, resulting in increased production capacity by 25% and reduced downtime by 40%

- Developed and implemented a preventative maintenance program for extrusion dies, which led to a 30% decrease in unscheduled repairs and improved overall equipment reliability

- Trained and mentored junior Extrusion Die Repairers, cultivating their skills and knowledge to ensure a highly competent team

- Collaborated with production engineers to optimize extrusion processes, leading to a 15% reduction in scrap rate and improved product quality

- Introduced lean manufacturing principles to the die repair workshop, resulting in a 20% increase in efficiency and reduced lead times

Awards

- Recognized with the Extrusion Die Repairer of the Year award for outstanding performance and contributions to the industry

- Received the Excellence in Die Repair award for innovative techniques and exceptional results in die repair and maintenance

- Honored with the Safety Champion award for implementing and maintaining exemplary safety practices in the extrusion die repair environment

- Certified by the Institute of Extrusion Die Repair as a Master Extrusion Die Repairer

Certificates

- Certified Extrusion Die Repairer

- Certified Welding Inspector

- Certified Quality Control Inspector

- Certified Safety Professional

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Extrusion Die Repairer

- Highlight your technical skills and experience in CNC machining, welding, and other relevant areas.

- Showcase your ability to diagnose and resolve complex extrusion die issues.

- Emphasize your commitment to safety and quality assurance.

- Provide specific examples of your accomplishments and the positive impact you have had on production efficiency.

- Tailor your resume to each job application, highlighting the skills and experience that are most relevant to the specific role.

Essential Experience Highlights for a Strong Extrusion Die Repairer Resume

- Diagnose and repair extrusion dies to ensure optimal production efficiency

- Perform CNC machining operations to create precise components and ensure accurate die alignment

- Utilize welding, brazing, soldering, grinding, and polishing techniques to repair and maintain dies

- Inspect and test repaired dies to ensure they meet specifications and quality standards

- Adhere to strict safety protocols and maintain a clean and organized work environment

- Collaborate with engineers and production team to identify and resolve die-related issues

- Stay up-to-date on industry best practices and advancements in die repair techniques

Frequently Asked Questions (FAQ’s) For Extrusion Die Repairer

What are the essential skills for an Extrusion Die Repairer?

Essential skills for an Extrusion Die Repairer include proficiency in CNC machining, welding, brazing, soldering, grinding, and polishing. They should also have a strong understanding of die design and manufacturing processes, as well as excellent problem-solving and analytical abilities.

What are the key responsibilities of an Extrusion Die Repairer?

Key responsibilities of an Extrusion Die Repairer include diagnosing and repairing extrusion dies, performing CNC machining operations, inspecting and testing repaired dies, collaborating with engineers and production team, and adhering to safety protocols.

What industries employ Extrusion Die Repairers?

Extrusion Die Repairers are employed in a variety of industries, including plastics, automotive, and aerospace. They work in manufacturing facilities, repair shops, and other industrial settings.

What is the job outlook for Extrusion Die Repairers?

The job outlook for Extrusion Die Repairers is expected to be positive in the coming years. The increasing demand for plastic products and the growing complexity of extrusion dies will drive the need for skilled repairers.

What are the career advancement opportunities for Extrusion Die Repairers?

With experience and additional training, Extrusion Die Repairers can advance to positions such as Extrusion Die Designer, Extrusion Process Engineer, or Maintenance Supervisor.

What are the typical working conditions for Extrusion Die Repairers?

Extrusion Die Repairers typically work in manufacturing facilities or repair shops. They may be exposed to noise, dust, and chemicals. They may also work in confined spaces or at heights.

What are the safety precautions that Extrusion Die Repairers must follow?

Extrusion Die Repairers must follow strict safety precautions, including wearing appropriate personal protective equipment, following lockout/tagout procedures, and being aware of potential hazards such as moving machinery and hot surfaces.

What are the professional organizations for Extrusion Die Repairers?

Professional organizations for Extrusion Die Repairers include the Society of Plastics Engineers (SPE) and the American Society for Nondestructive Testing (ASNT).