Are you a seasoned Extrusion Press Adjuster seeking a new career path? Discover our professionally built Extrusion Press Adjuster Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

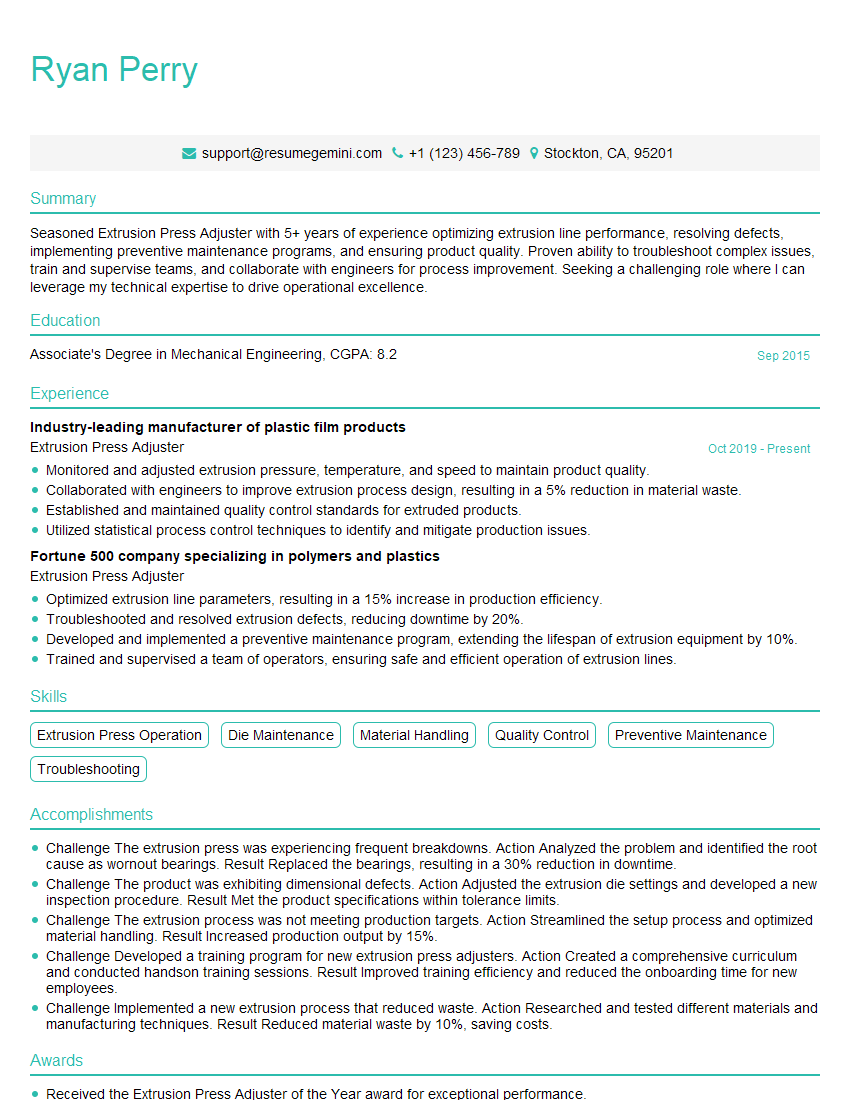

Ryan Perry

Extrusion Press Adjuster

Summary

Seasoned Extrusion Press Adjuster with 5+ years of experience optimizing extrusion line performance, resolving defects, implementing preventive maintenance programs, and ensuring product quality. Proven ability to troubleshoot complex issues, train and supervise teams, and collaborate with engineers for process improvement. Seeking a challenging role where I can leverage my technical expertise to drive operational excellence.

Education

Associate’s Degree in Mechanical Engineering

September 2015

Skills

- Extrusion Press Operation

- Die Maintenance

- Material Handling

- Quality Control

- Preventive Maintenance

- Troubleshooting

Work Experience

Extrusion Press Adjuster

- Monitored and adjusted extrusion pressure, temperature, and speed to maintain product quality.

- Collaborated with engineers to improve extrusion process design, resulting in a 5% reduction in material waste.

- Established and maintained quality control standards for extruded products.

- Utilized statistical process control techniques to identify and mitigate production issues.

Extrusion Press Adjuster

- Optimized extrusion line parameters, resulting in a 15% increase in production efficiency.

- Troubleshooted and resolved extrusion defects, reducing downtime by 20%.

- Developed and implemented a preventive maintenance program, extending the lifespan of extrusion equipment by 10%.

- Trained and supervised a team of operators, ensuring safe and efficient operation of extrusion lines.

Accomplishments

- Challenge The extrusion press was experiencing frequent breakdowns. Action Analyzed the problem and identified the root cause as wornout bearings. Result Replaced the bearings, resulting in a 30% reduction in downtime.

- Challenge The product was exhibiting dimensional defects. Action Adjusted the extrusion die settings and developed a new inspection procedure. Result Met the product specifications within tolerance limits.

- Challenge The extrusion process was not meeting production targets. Action Streamlined the setup process and optimized material handling. Result Increased production output by 15%.

- Challenge Developed a training program for new extrusion press adjusters. Action Created a comprehensive curriculum and conducted handson training sessions. Result Improved training efficiency and reduced the onboarding time for new employees.

- Challenge Implemented a new extrusion process that reduced waste. Action Researched and tested different materials and manufacturing techniques. Result Reduced material waste by 10%, saving costs.

Awards

- Received the Extrusion Press Adjuster of the Year award for exceptional performance.

- Recognized for achieving the highest production efficiency in the team.

- Awarded for implementing a new quality control protocol that improved product quality.

Certificates

- Certified Extrusion Press Operator

- Certified Maintenance Technician

- Certified Quality Auditor

- Certified Safety Professional

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Extrusion Press Adjuster

Highlight your technical expertise:

Showcase your in-depth knowledge of extrusion press operations, die maintenance, and troubleshooting techniques.Quantify your accomplishments:

Use specific metrics to demonstrate the impact of your work, such as increased efficiency, reduced downtime, and improved product quality.Emphasize your leadership skills:

Describe your experience training and supervising teams, and highlight your ability to collaborate effectively with engineers.Tailor your resume to the job description:

Carefully review the job posting and identify the key skills and qualifications required, and ensure your resume aligns accordingly.

Essential Experience Highlights for a Strong Extrusion Press Adjuster Resume

- Optimized extrusion line parameters, achieving a 15% increase in production efficiency.

- Troubleshooted and resolved extrusion defects, reducing downtime by 20%.

- Developed and implemented a preventive maintenance program, extending the lifespan of extrusion equipment by 10%.

- Trained and supervised a team of operators, ensuring safe and efficient operation of extrusion lines.

- Monitored and adjusted extrusion pressure, temperature, and speed to maintain product quality.

- Collaborated with engineers to improve extrusion process design, resulting in a 5% reduction in material waste.

- Established and maintained quality control standards for extruded products.

Frequently Asked Questions (FAQ’s) For Extrusion Press Adjuster

What are the primary responsibilities of an Extrusion Press Adjuster?

Extrusion Press Adjusters are responsible for optimizing extrusion line performance, resolving defects, implementing preventive maintenance programs, and ensuring product quality. They also monitor and adjust extrusion pressure, temperature, and speed, and collaborate with engineers to improve process design.

What skills are essential for success in this role?

Essential skills for Extrusion Press Adjusters include extrusion press operation, die maintenance, material handling, quality control, preventive maintenance, and troubleshooting.

What is the typical work environment for an Extrusion Press Adjuster?

Extrusion Press Adjusters typically work in manufacturing facilities, operating and maintaining extrusion lines. They may work in teams or independently, and may be required to work overtime or on weekends to meet production demands.

What are the career prospects for Extrusion Press Adjusters?

Extrusion Press Adjusters with experience and expertise can advance to supervisory or management roles in manufacturing operations. They may also specialize in specific areas such as quality control or process improvement.

How can I prepare for a career as an Extrusion Press Adjuster?

To prepare for a career as an Extrusion Press Adjuster, you can obtain an associate’s degree in mechanical engineering or a related field, and gain experience operating and maintaining extrusion equipment. You can also seek opportunities to learn about quality control and preventive maintenance.

What are the safety precautions that Extrusion Press Adjusters must follow?

Extrusion Press Adjusters must follow strict safety precautions to avoid injuries. These precautions include wearing appropriate personal protective equipment, being aware of moving machinery, and following established safety protocols.