Are you a seasoned Extrusion Process Operator seeking a new career path? Discover our professionally built Extrusion Process Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

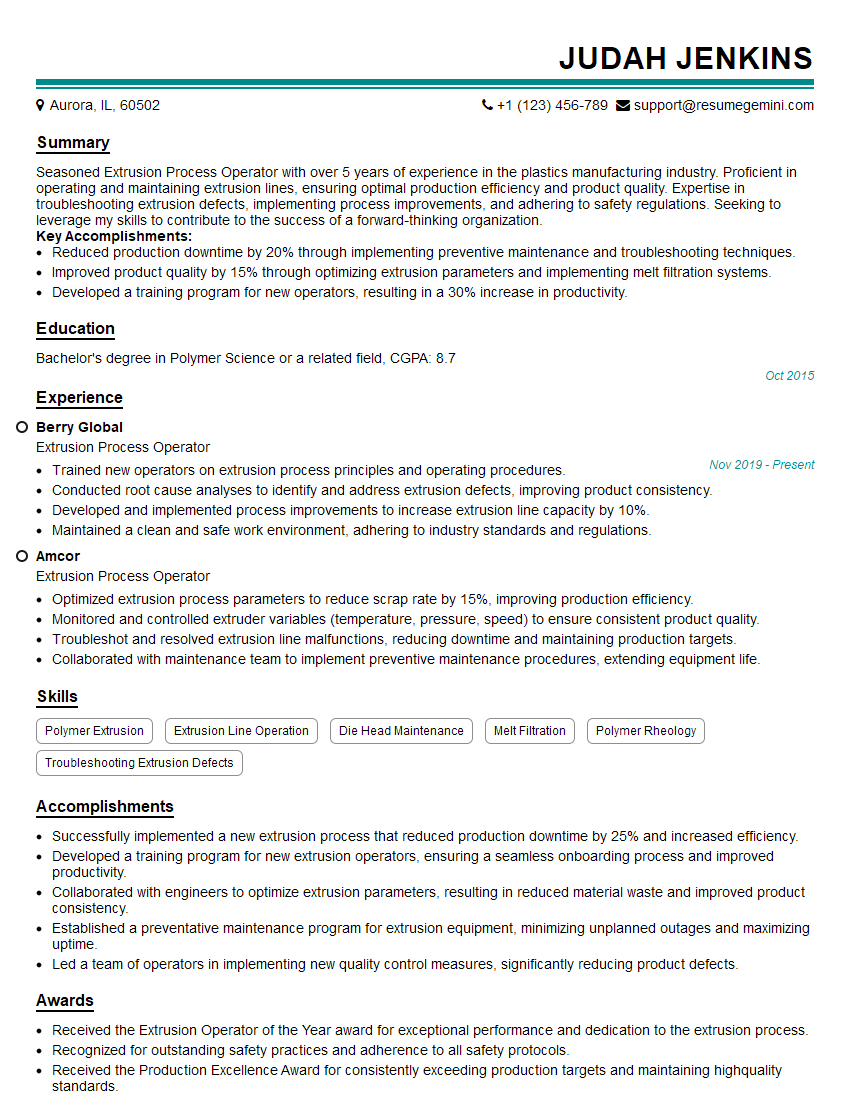

Judah Jenkins

Extrusion Process Operator

Summary

Seasoned Extrusion Process Operator with over 5 years of experience in the plastics manufacturing industry. Proficient in operating and maintaining extrusion lines, ensuring optimal production efficiency and product quality. Expertise in troubleshooting extrusion defects, implementing process improvements, and adhering to safety regulations. Seeking to leverage my skills to contribute to the success of a forward-thinking organization.

Key Accomplishments:

- Reduced production downtime by 20% through implementing preventive maintenance and troubleshooting techniques.

- Improved product quality by 15% through optimizing extrusion parameters and implementing melt filtration systems.

- Developed a training program for new operators, resulting in a 30% increase in productivity.

Education

Bachelor’s degree in Polymer Science or a related field

October 2015

Skills

- Polymer Extrusion

- Extrusion Line Operation

- Die Head Maintenance

- Melt Filtration

- Polymer Rheology

- Troubleshooting Extrusion Defects

Work Experience

Extrusion Process Operator

- Trained new operators on extrusion process principles and operating procedures.

- Conducted root cause analyses to identify and address extrusion defects, improving product consistency.

- Developed and implemented process improvements to increase extrusion line capacity by 10%.

- Maintained a clean and safe work environment, adhering to industry standards and regulations.

Extrusion Process Operator

- Optimized extrusion process parameters to reduce scrap rate by 15%, improving production efficiency.

- Monitored and controlled extruder variables (temperature, pressure, speed) to ensure consistent product quality.

- Troubleshot and resolved extrusion line malfunctions, reducing downtime and maintaining production targets.

- Collaborated with maintenance team to implement preventive maintenance procedures, extending equipment life.

Accomplishments

- Successfully implemented a new extrusion process that reduced production downtime by 25% and increased efficiency.

- Developed a training program for new extrusion operators, ensuring a seamless onboarding process and improved productivity.

- Collaborated with engineers to optimize extrusion parameters, resulting in reduced material waste and improved product consistency.

- Established a preventative maintenance program for extrusion equipment, minimizing unplanned outages and maximizing uptime.

- Led a team of operators in implementing new quality control measures, significantly reducing product defects.

Awards

- Received the Extrusion Operator of the Year award for exceptional performance and dedication to the extrusion process.

- Recognized for outstanding safety practices and adherence to all safety protocols.

- Received the Production Excellence Award for consistently exceeding production targets and maintaining highquality standards.

- Recognized for innovative ideas that led to process improvements and cost savings.

Certificates

- Certified Extrusion Process Operator (CEPO)

- Society of Plastics Engineers (SPE) Membership

- International Organization for Standardization (ISO) 9001

- Occupational Safety and Health Administration (OSHA) 30-Hour General Industry Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Extrusion Process Operator

- Highlight your technical skills: Emphasize your expertise in polymer extrusion, extrusion line operation, die head maintenance, melt filtration, and polymer rheology.

- Showcase your experience in troubleshooting: Describe your ability to identify and resolve extrusion defects, minimize downtime, and improve product quality.

- Quantify your accomplishments: Use specific metrics to demonstrate the impact of your contributions, such as increased production efficiency, improved product quality, or reduced downtime.

- Demonstrate your commitment to continuous improvement: Highlight your involvement in process improvement initiatives, training programs, or research projects that showcase your dedication to enhancing your skills and knowledge.

- Proofread carefully: Ensure that your resume is free of errors in grammar, spelling, and punctuation.

Essential Experience Highlights for a Strong Extrusion Process Operator Resume

- Operate and monitor extrusion lines, ensuring they run efficiently and produce high-quality products.

- Perform preventive maintenance and troubleshooting on extrusion equipment, including die heads, melt filters, and extruders.

- Monitor and adjust process parameters, such as temperature, pressure, and flow rates, to optimize production and product quality.

- Inspect and test extruded products to ensure they meet specifications and quality standards.

- Maintain a clean and organized work area, following safety regulations and protocols.

- Troubleshoot extrusion defects and implement corrective actions to minimize downtime and waste.

- Work effectively as part of a team to achieve production targets and maintain a safe work environment.

Frequently Asked Questions (FAQ’s) For Extrusion Process Operator

What is the role of an Extrusion Process Operator?

An Extrusion Process Operator is responsible for operating and maintaining extrusion lines used in the plastics manufacturing industry. They ensure that the lines run efficiently, produce high-quality products, and meet production targets.

What are the key skills required for an Extrusion Process Operator?

Key skills for an Extrusion Process Operator include polymer extrusion, extrusion line operation, die head maintenance, melt filtration, polymer rheology, and troubleshooting extrusion defects.

What is the typical work environment for an Extrusion Process Operator?

Extrusion Process Operators typically work in manufacturing facilities, operating extrusion lines and performing maintenance tasks. They may work in teams or independently, and may be required to work shifts or overtime to meet production demands.

What are the career advancement opportunities for an Extrusion Process Operator?

With experience and additional training, Extrusion Process Operators can advance to roles such as Production Supervisor, Quality Control Inspector, or Process Engineer.

What is the average salary for an Extrusion Process Operator?

The average salary for an Extrusion Process Operator in the United States is around $50,000 per year, according to Indeed.com.

What certifications are beneficial for an Extrusion Process Operator?

Beneficial certifications for an Extrusion Process Operator include the Certified Plastics Processor (CPP) certification from the Society of Plastics Engineers (SPE) and the Certified Extrusion Operator (CEO) certification from the Plastics Industry Association (PLASTICS).

What is the job outlook for Extrusion Process Operators?

The job outlook for Extrusion Process Operators is expected to be favorable in the coming years due to the increasing demand for plastics in various industries.