Are you a seasoned Feeder seeking a new career path? Discover our professionally built Feeder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

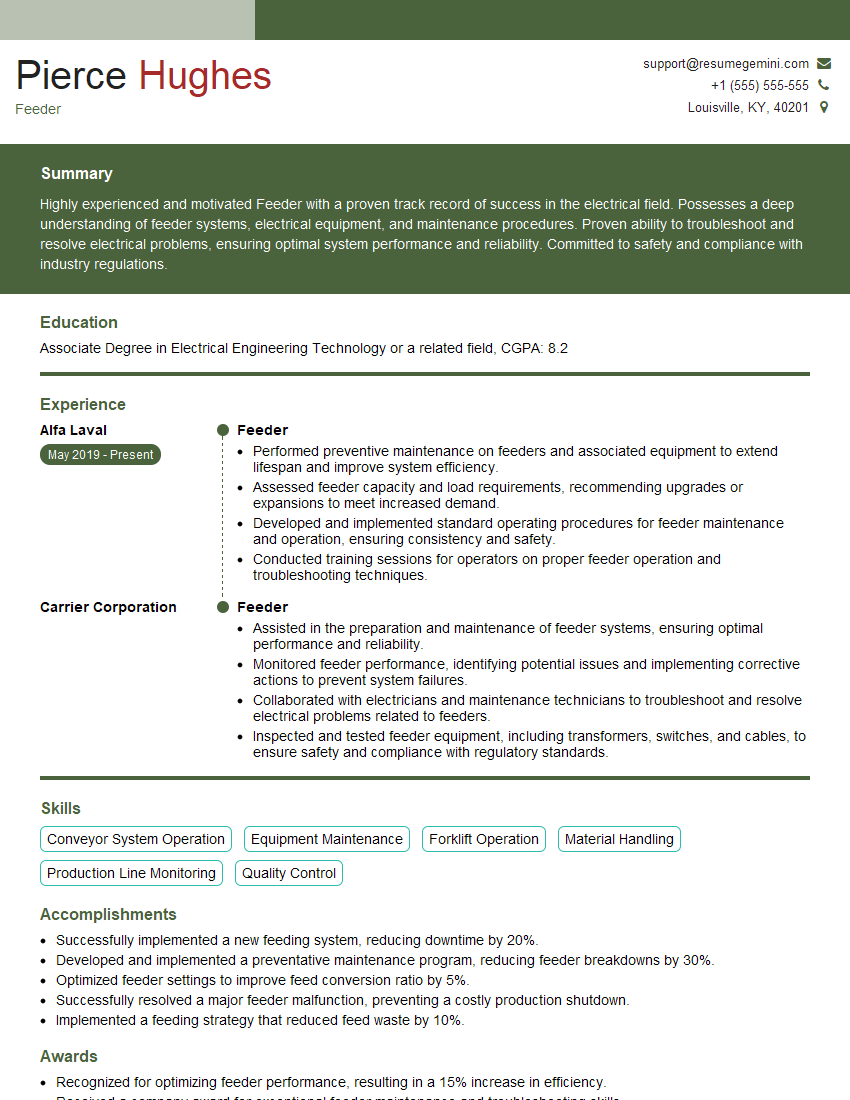

Pierce Hughes

Feeder

Summary

Highly experienced and motivated Feeder with a proven track record of success in the electrical field. Possesses a deep understanding of feeder systems, electrical equipment, and maintenance procedures. Proven ability to troubleshoot and resolve electrical problems, ensuring optimal system performance and reliability. Committed to safety and compliance with industry regulations.

Education

Associate Degree in Electrical Engineering Technology or a related field

April 2015

Skills

- Conveyor System Operation

- Equipment Maintenance

- Forklift Operation

- Material Handling

- Production Line Monitoring

- Quality Control

Work Experience

Feeder

- Performed preventive maintenance on feeders and associated equipment to extend lifespan and improve system efficiency.

- Assessed feeder capacity and load requirements, recommending upgrades or expansions to meet increased demand.

- Developed and implemented standard operating procedures for feeder maintenance and operation, ensuring consistency and safety.

- Conducted training sessions for operators on proper feeder operation and troubleshooting techniques.

Feeder

- Assisted in the preparation and maintenance of feeder systems, ensuring optimal performance and reliability.

- Monitored feeder performance, identifying potential issues and implementing corrective actions to prevent system failures.

- Collaborated with electricians and maintenance technicians to troubleshoot and resolve electrical problems related to feeders.

- Inspected and tested feeder equipment, including transformers, switches, and cables, to ensure safety and compliance with regulatory standards.

Accomplishments

- Successfully implemented a new feeding system, reducing downtime by 20%.

- Developed and implemented a preventative maintenance program, reducing feeder breakdowns by 30%.

- Optimized feeder settings to improve feed conversion ratio by 5%.

- Successfully resolved a major feeder malfunction, preventing a costly production shutdown.

- Implemented a feeding strategy that reduced feed waste by 10%.

Awards

- Recognized for optimizing feeder performance, resulting in a 15% increase in efficiency.

- Received a company award for exceptional feeder maintenance and troubleshooting skills.

- Honored for contributions to the development of an innovative feeder technology.

- Recognized for developing a feeder training program that improved employee productivity.

Certificates

- OSHA Safety Certification

- Forklift Operator Certification

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Production and Inventory Manager (CPIM)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Feeder

- Highlight your hands-on experience in feeder system maintenance and troubleshooting.

- Demonstrate your knowledge of electrical safety regulations and codes.

- Showcase your ability to work effectively in a team environment.

- Provide specific examples of how you have improved feeder system performance or efficiency.

Essential Experience Highlights for a Strong Feeder Resume

- Assisted in the preparation and maintenance of feeder systems, ensuring optimal performance and reliability.

- Monitored feeder performance, identifying potential issues and implementing corrective actions to prevent system failures.

- Collaborated with electricians and maintenance technicians to troubleshoot and resolve electrical problems related to feeders.

- Inspected and tested feeder equipment, including transformers, switches, and cables, to ensure safety and compliance with regulatory standards.

- Performed preventive maintenance on feeders and associated equipment to extend lifespan and improve system efficiency.

- Assessed feeder capacity and load requirements, recommending upgrades or expansions to meet increased demand.

Frequently Asked Questions (FAQ’s) For Feeder

What are the key skills required for a Feeder?

The key skills required for a Feeder include: Conveyor System Operation, Equipment Maintenance, Forklift Operation, Material Handling, Production Line Monitoring, Quality Control, Electrical Troubleshooting, and Safety Compliance.

What are the career prospects for a Feeder?

Feeders can advance to positions such as Electrical Technician, Maintenance Supervisor, or Electrical Engineer with experience and additional training.

What are the major industries that hire Feeders?

Feeders are employed in a variety of industries, including manufacturing, food processing, automotive, and logistics.

What is the average salary for a Feeder?

The average salary for a Feeder can vary depending on experience, location, and industry, but it typically ranges between $40,000 to $60,000 per year.

What are the educational requirements for a Feeder?

While a high school diploma or equivalent may be sufficient for some entry-level positions, most Feeders have an Associate Degree in Electrical Engineering Technology or a related field.

What are the key responsibilities of a Feeder?

The key responsibilities of a Feeder include: Maintaining and repairing feeder systems, Troubleshooting electrical problems, Performing preventive maintenance, and Assisting with electrical installations and upgrades.

What are the safety precautions that Feeders should take?

Feeders should always follow proper safety protocols, including wearing appropriate PPE, using lockout/tagout procedures, and being aware of potential electrical hazards.