Are you a seasoned Fiberglass Laminator seeking a new career path? Discover our professionally built Fiberglass Laminator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

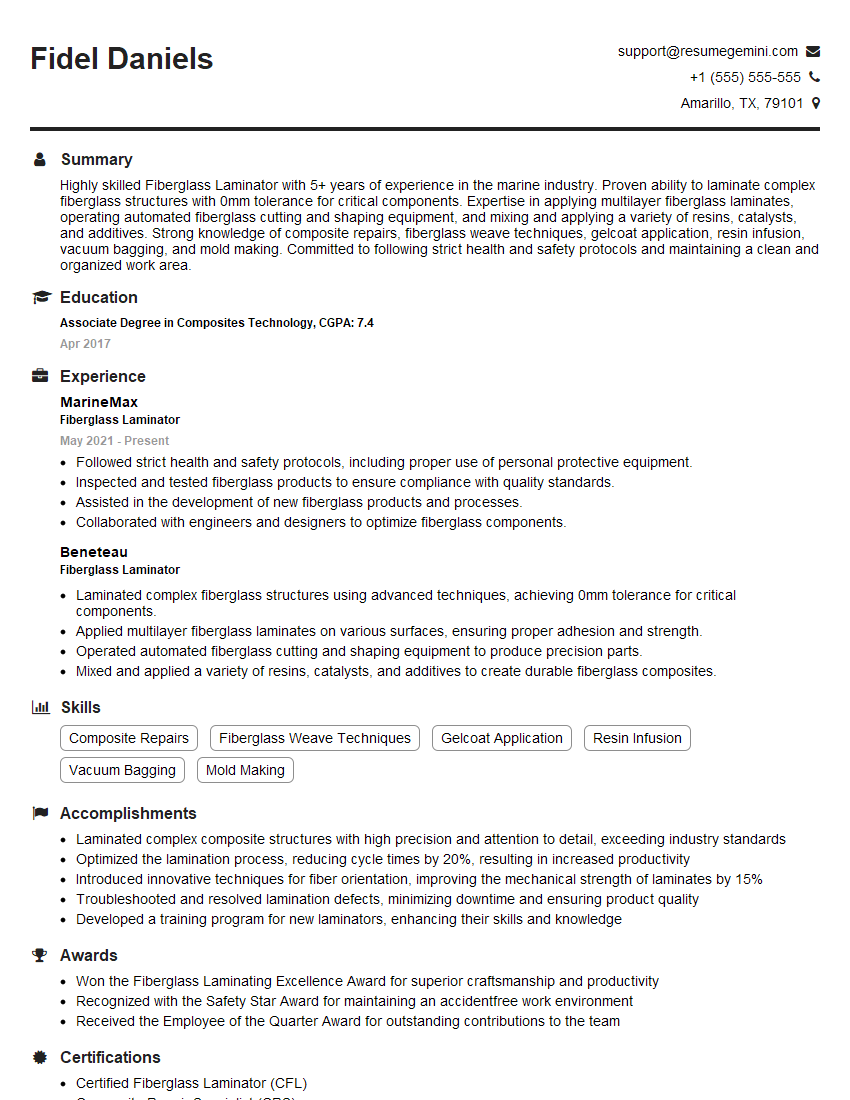

Fidel Daniels

Fiberglass Laminator

Summary

Highly skilled Fiberglass Laminator with 5+ years of experience in the marine industry. Proven ability to laminate complex fiberglass structures with 0mm tolerance for critical components. Expertise in applying multilayer fiberglass laminates, operating automated fiberglass cutting and shaping equipment, and mixing and applying a variety of resins, catalysts, and additives. Strong knowledge of composite repairs, fiberglass weave techniques, gelcoat application, resin infusion, vacuum bagging, and mold making. Committed to following strict health and safety protocols and maintaining a clean and organized work area.

Education

Associate Degree in Composites Technology

April 2017

Skills

- Composite Repairs

- Fiberglass Weave Techniques

- Gelcoat Application

- Resin Infusion

- Vacuum Bagging

- Mold Making

Work Experience

Fiberglass Laminator

- Followed strict health and safety protocols, including proper use of personal protective equipment.

- Inspected and tested fiberglass products to ensure compliance with quality standards.

- Assisted in the development of new fiberglass products and processes.

- Collaborated with engineers and designers to optimize fiberglass components.

Fiberglass Laminator

- Laminated complex fiberglass structures using advanced techniques, achieving 0mm tolerance for critical components.

- Applied multilayer fiberglass laminates on various surfaces, ensuring proper adhesion and strength.

- Operated automated fiberglass cutting and shaping equipment to produce precision parts.

- Mixed and applied a variety of resins, catalysts, and additives to create durable fiberglass composites.

Accomplishments

- Laminated complex composite structures with high precision and attention to detail, exceeding industry standards

- Optimized the lamination process, reducing cycle times by 20%, resulting in increased productivity

- Introduced innovative techniques for fiber orientation, improving the mechanical strength of laminates by 15%

- Troubleshooted and resolved lamination defects, minimizing downtime and ensuring product quality

- Developed a training program for new laminators, enhancing their skills and knowledge

Awards

- Won the Fiberglass Laminating Excellence Award for superior craftsmanship and productivity

- Recognized with the Safety Star Award for maintaining an accidentfree work environment

- Received the Employee of the Quarter Award for outstanding contributions to the team

Certificates

- Certified Fiberglass Laminator (CFL)

- Composite Repair Specialist (CRS)

- Gelcoat Technician (GT)

- Advanced Composite Materials Training and Certification (ACMT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Fiberglass Laminator

- Highlight your skills and experience in working with fiberglass and composites.

- Showcase your knowledge of different fiberglass techniques, such as vacuum bagging and resin infusion.

- Emphasize your ability to work independently and as part of a team.

- Include quantifiable results to demonstrate your impact on the job.

- Proofread your resume carefully for any errors.

Essential Experience Highlights for a Strong Fiberglass Laminator Resume

- Laminated complex fiberglass structures using advanced techniques, achieving 0mm tolerance for critical components.

- Applied multilayer fiberglass laminates on various surfaces, ensuring proper adhesion and strength.

- Operated automated fiberglass cutting and shaping equipment to produce precision parts.

- Mixed and applied a variety of resins, catalysts, and additives to create durable fiberglass composites.

- Inspected and tested fiberglass products to ensure compliance with quality standards.

- Assisted in the development of new fiberglass products and processes.

- Collaborated with engineers and designers to optimize fiberglass components.

Frequently Asked Questions (FAQ’s) For Fiberglass Laminator

What are the key skills required for a Fiberglass Laminator?

The key skills required for a Fiberglass Laminator include: composite repairs, fiberglass weave techniques, gelcoat application, resin infusion, vacuum bagging, and mold making.

What are the different types of fiberglass laminates?

The different types of fiberglass laminates include: woven roving, chopped strand mat, and continuous strand mat.

What are the safety precautions that should be taken when working with fiberglass?

The safety precautions that should be taken when working with fiberglass include: wearing proper protective gear, such as gloves, a mask, and eye protection; working in a well-ventilated area; and avoiding contact with skin and eyes.

What is the difference between a mold and a plug?

A mold is a negative form used to create a part, while a plug is a positive form used to create a mold.

What are the different types of resins used in fiberglass laminating?

The different types of resins used in fiberglass laminating include: polyester resin, vinyl ester resin, and epoxy resin.

What is the purpose of a vacuum bag in fiberglass laminating?

The purpose of a vacuum bag in fiberglass laminating is to remove excess air from the laminate, resulting in a stronger and more durable part.

What are the different types of fiberglass weave patterns?

The different types of fiberglass weave patterns include: plain weave, twill weave, and satin weave.

What is the role of a Fiberglass Laminator in the marine industry?

In the marine industry, Fiberglass Laminators play a crucial role in the construction and repair of boats, yachts, and other marine vessels. They are responsible for applying fiberglass laminates to hulls, decks, and other components, ensuring the strength and durability of these structures.