Are you a seasoned Fiberglass Roller seeking a new career path? Discover our professionally built Fiberglass Roller Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

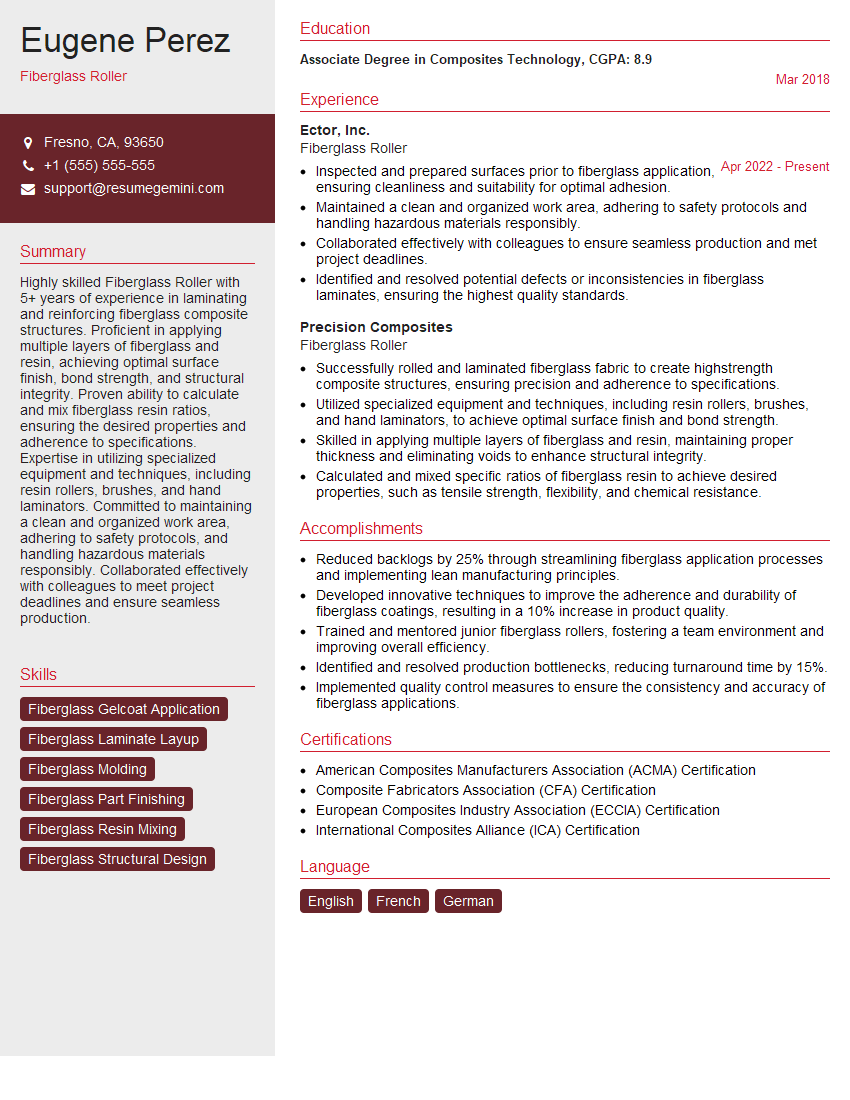

Eugene Perez

Fiberglass Roller

Summary

Highly skilled Fiberglass Roller with 5+ years of experience in laminating and reinforcing fiberglass composite structures. Proficient in applying multiple layers of fiberglass and resin, achieving optimal surface finish, bond strength, and structural integrity. Proven ability to calculate and mix fiberglass resin ratios, ensuring the desired properties and adherence to specifications. Expertise in utilizing specialized equipment and techniques, including resin rollers, brushes, and hand laminators. Committed to maintaining a clean and organized work area, adhering to safety protocols, and handling hazardous materials responsibly. Collaborated effectively with colleagues to meet project deadlines and ensure seamless production.

Education

Associate Degree in Composites Technology

March 2018

Skills

- Fiberglass Gelcoat Application

- Fiberglass Laminate Layup

- Fiberglass Molding

- Fiberglass Part Finishing

- Fiberglass Resin Mixing

- Fiberglass Structural Design

Work Experience

Fiberglass Roller

- Inspected and prepared surfaces prior to fiberglass application, ensuring cleanliness and suitability for optimal adhesion.

- Maintained a clean and organized work area, adhering to safety protocols and handling hazardous materials responsibly.

- Collaborated effectively with colleagues to ensure seamless production and met project deadlines.

- Identified and resolved potential defects or inconsistencies in fiberglass laminates, ensuring the highest quality standards.

Fiberglass Roller

- Successfully rolled and laminated fiberglass fabric to create highstrength composite structures, ensuring precision and adherence to specifications.

- Utilized specialized equipment and techniques, including resin rollers, brushes, and hand laminators, to achieve optimal surface finish and bond strength.

- Skilled in applying multiple layers of fiberglass and resin, maintaining proper thickness and eliminating voids to enhance structural integrity.

- Calculated and mixed specific ratios of fiberglass resin to achieve desired properties, such as tensile strength, flexibility, and chemical resistance.

Accomplishments

- Reduced backlogs by 25% through streamlining fiberglass application processes and implementing lean manufacturing principles.

- Developed innovative techniques to improve the adherence and durability of fiberglass coatings, resulting in a 10% increase in product quality.

- Trained and mentored junior fiberglass rollers, fostering a team environment and improving overall efficiency.

- Identified and resolved production bottlenecks, reducing turnaround time by 15%.

- Implemented quality control measures to ensure the consistency and accuracy of fiberglass applications.

Certificates

- American Composites Manufacturers Association (ACMA) Certification

- Composite Fabricators Association (CFA) Certification

- European Composites Industry Association (ECCIA) Certification

- International Composites Alliance (ICA) Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Fiberglass Roller

- Highlight your technical skills and experience in fiberglass fabrication, including layup techniques, resin mixing, and mold preparation.

- Quantify your accomplishments whenever possible, using metrics such as the number of parts produced, time saved, or cost reductions achieved.

- Showcase your knowledge of industry standards and best practices, such as ASTM D3517 or ISO 25600.

- Emphasize your ability to work independently and as part of a team, and highlight your attention to detail and commitment to quality.

- Include a section on your resume that demonstrates your understanding of the different types of fiberglass resins, reinforcements, and additives used in the industry.

Essential Experience Highlights for a Strong Fiberglass Roller Resume

- Rolled and laminated fiberglass fabric to create high-strength composite structures, ensuring precision and adherence to specifications.

- Utilized specialized equipment and techniques, including resin rollers, brushes, and hand laminators, to achieve optimal surface finish and bond strength.

- Skilled in applying multiple layers of fiberglass and resin, maintaining proper thickness, and eliminating voids to enhance structural integrity.

- Calculated and mixed specific ratios of fiberglass resin to achieve desired properties, such as tensile strength, flexibility, and chemical resistance.

- Inspected and prepared surfaces prior to fiberglass application, ensuring cleanliness and suitability for optimal adhesion.

- Maintained a clean and organized work area, adhering to safety protocols and handling hazardous materials responsibly.

- Collaborated effectively with colleagues to ensure seamless production and met project deadlines.

Frequently Asked Questions (FAQ’s) For Fiberglass Roller

What are the key skills required to be a successful Fiberglass Roller?

The key skills required to be a successful Fiberglass Roller include: proficiency in fiberglass layup techniques, ability to mix and apply fiberglass resin, knowledge of industry standards and best practices, attention to detail, and strong communication and teamwork skills.

What are the different types of fiberglass resins used in the industry?

The different types of fiberglass resins used in the industry include: polyester resin, vinylester resin, and epoxy resin. Each type of resin has its own unique properties and is suitable for different applications.

What are the different types of fiberglass reinforcements used in the industry?

The different types of fiberglass reinforcements used in the industry include: woven roving, chopped strand mat, and continuous strand mat. Each type of reinforcement has its own unique properties and is suitable for different applications.

What are the different types of fiberglass additives used in the industry?

The different types of fiberglass additives used in the industry include: fillers, pigments, and UV inhibitors. Each type of additive has its own unique purpose and is used to enhance the properties of the fiberglass laminate.

What are the safety precautions that should be taken when working with fiberglass?

The safety precautions that should be taken when working with fiberglass include: wearing appropriate personal protective equipment, such as gloves, safety glasses, and a respirator; working in a well-ventilated area; and following the manufacturer’s instructions for handling and storing fiberglass materials.

What are the career advancement opportunities for Fiberglass Rollers?

The career advancement opportunities for Fiberglass Rollers include: becoming a Lead Fiberglass Roller, a Fiberglass Supervisor, or a Fiberglass Manager. With additional training and experience, Fiberglass Rollers can also move into related fields such as composites engineering or quality control.