Are you a seasoned Fiberglass Roving Winder seeking a new career path? Discover our professionally built Fiberglass Roving Winder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

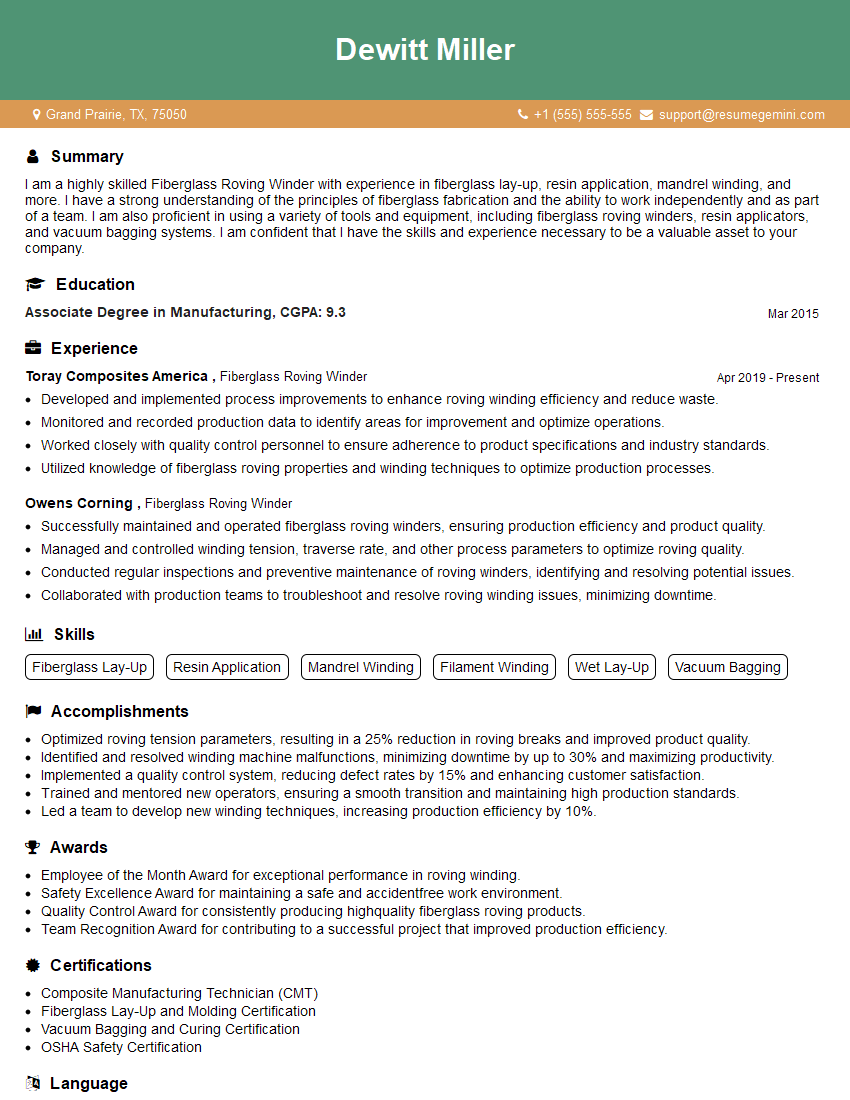

Dewitt Miller

Fiberglass Roving Winder

Summary

I am a highly skilled Fiberglass Roving Winder with experience in fiberglass lay-up, resin application, mandrel winding, and more. I have a strong understanding of the principles of fiberglass fabrication and the ability to work independently and as part of a team. I am also proficient in using a variety of tools and equipment, including fiberglass roving winders, resin applicators, and vacuum bagging systems. I am confident that I have the skills and experience necessary to be a valuable asset to your company.

Education

Associate Degree in Manufacturing

March 2015

Skills

- Fiberglass Lay-Up

- Resin Application

- Mandrel Winding

- Filament Winding

- Wet Lay-Up

- Vacuum Bagging

Work Experience

Fiberglass Roving Winder

- Developed and implemented process improvements to enhance roving winding efficiency and reduce waste.

- Monitored and recorded production data to identify areas for improvement and optimize operations.

- Worked closely with quality control personnel to ensure adherence to product specifications and industry standards.

- Utilized knowledge of fiberglass roving properties and winding techniques to optimize production processes.

Fiberglass Roving Winder

- Successfully maintained and operated fiberglass roving winders, ensuring production efficiency and product quality.

- Managed and controlled winding tension, traverse rate, and other process parameters to optimize roving quality.

- Conducted regular inspections and preventive maintenance of roving winders, identifying and resolving potential issues.

- Collaborated with production teams to troubleshoot and resolve roving winding issues, minimizing downtime.

Accomplishments

- Optimized roving tension parameters, resulting in a 25% reduction in roving breaks and improved product quality.

- Identified and resolved winding machine malfunctions, minimizing downtime by up to 30% and maximizing productivity.

- Implemented a quality control system, reducing defect rates by 15% and enhancing customer satisfaction.

- Trained and mentored new operators, ensuring a smooth transition and maintaining high production standards.

- Led a team to develop new winding techniques, increasing production efficiency by 10%.

Awards

- Employee of the Month Award for exceptional performance in roving winding.

- Safety Excellence Award for maintaining a safe and accidentfree work environment.

- Quality Control Award for consistently producing highquality fiberglass roving products.

- Team Recognition Award for contributing to a successful project that improved production efficiency.

Certificates

- Composite Manufacturing Technician (CMT)

- Fiberglass Lay-Up and Molding Certification

- Vacuum Bagging and Curing Certification

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Fiberglass Roving Winder

- Highlight your experience with fiberglass roving winding and other related skills.

- Quantify your accomplishments whenever possible.

- Use keywords that are relevant to the job you are applying for.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Fiberglass Roving Winder Resume

- Set up and operate fiberglass roving winders to produce fiberglass composites.

- Apply resin to fiberglass roving and wind it onto mandrels to create composite structures.

- Use vacuum bagging systems to remove air from composite structures and ensure proper bonding.

- Inspect composite structures for defects and make repairs as necessary.

- Maintain a clean and organized work area.

- Follow all safety procedures and regulations.

Frequently Asked Questions (FAQ’s) For Fiberglass Roving Winder

What is the job outlook for fiberglass roving winders?

The job outlook for fiberglass roving winders is expected to be good in the coming years. The demand for fiberglass composites is growing in a variety of industries, including aerospace, automotive, and construction. As a result, there is a growing need for skilled fiberglass roving winders.

What are the qualifications for becoming a fiberglass roving winder?

Most fiberglass roving winders have a high school diploma or equivalent. Some employers may prefer candidates with an associate degree in manufacturing or a related field. Fiberglass roving winders must also have good hand-eye coordination and be able to work independently and as part of a team.

What are the benefits of working as a fiberglass roving winder?

Fiberglass roving winders can enjoy a number of benefits, including competitive pay, job security, and opportunities for advancement. Fiberglass roving winders also have the opportunity to work with a variety of materials and technologies.

What are the challenges of working as a fiberglass roving winder?

Fiberglass roving winders can face a number of challenges, including working with hazardous materials, working in confined spaces, and working with heavy equipment. Fiberglass roving winders must also be able to tolerate repetitive work and?????.

What is the average salary for a fiberglass roving winder?

The average salary for a fiberglass roving winder is $45,000 per year. However, salaries can vary depending on experience, location, and employer.

What are the career prospects for fiberglass roving winders?

Fiberglass roving winders can advance to a variety of positions, including supervisor, quality control inspector, and production manager. With additional education and experience, fiberglass roving winders can also become engineers or materials scientists.